Wheel disc type hydraulic motor

A wheel-type, water-pressure technology, applied in the field of motors, can solve the problems of low reuse rate, waste of energy costs, flammability, etc., and achieve the effect of high reuse rate, energy saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

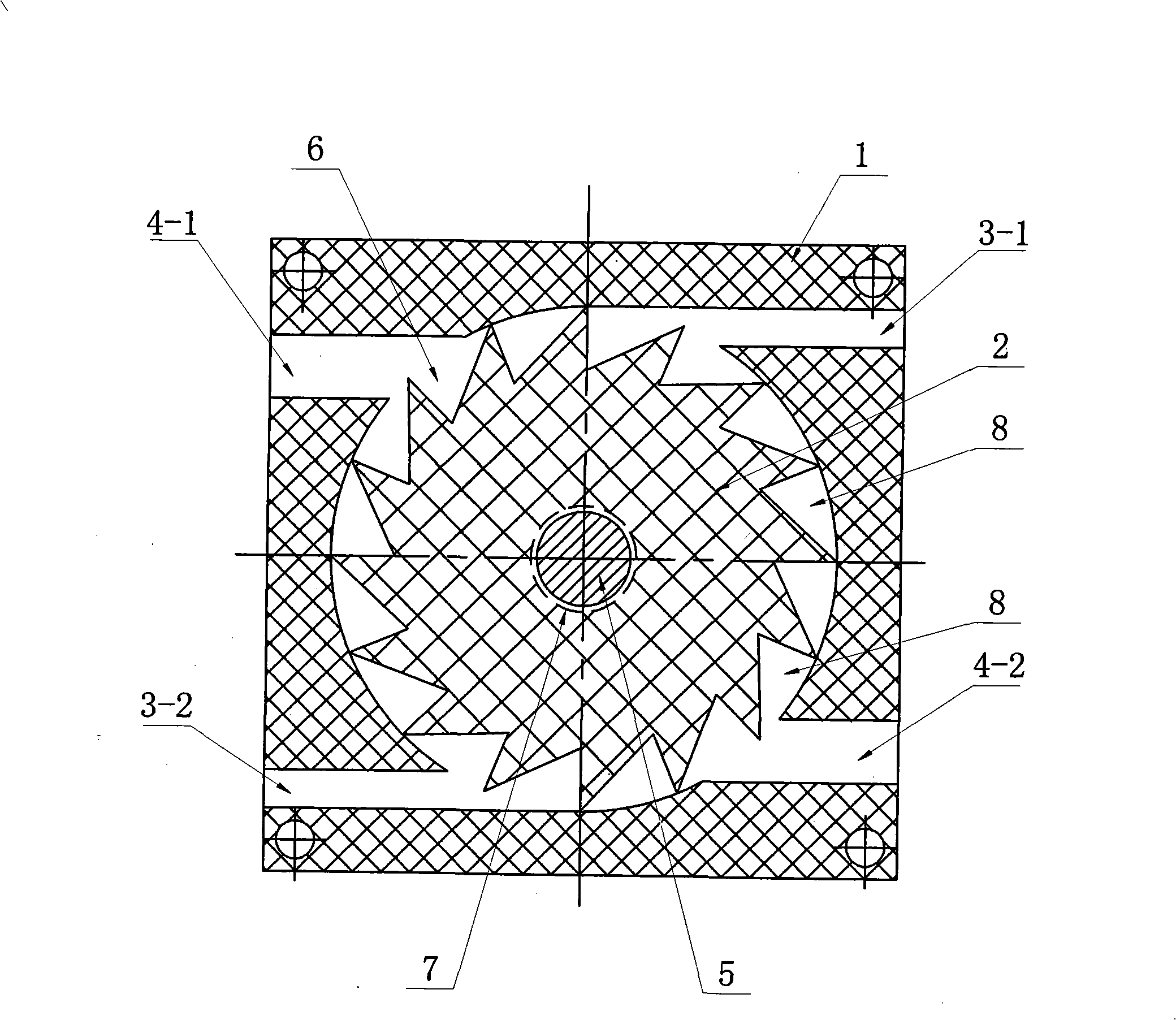

[0007] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment consists of a housing 1, a gear plate 2, a first water inlet channel 3-1, a second water inlet channel 3-2, a first water outlet channel 4-1, a second water outlet channel 4-2, and a power output shaft 5 Composed of sealing ring 7, housing 1 is provided with cavity 6, gear disc 2 is located in the cavity, the center of gear disc 2 is provided with power output shaft 5, and the first water inlet channel 3-1 is located in housing 1 The upper right end of the upper part, the first water outlet channel 4-1 is located at the left end of the upper part of the housing 1, the second water inlet channel 3-2 is located at the left end of the lower part of the housing 1, and the second water outlet channel 4-2 is located at the upper left end of the housing 1. The right end of the lower part of the body 1, the first water inlet channel 3-1, the second water inlet channel 3...

specific Embodiment approach 2

[0008] Embodiment 2: In this embodiment, a plurality of semi-closed and closed water cavities 8 are formed between the inner wall of the casing 1 and the teeth of the gear plate 2 .

specific Embodiment approach 3

[0009] Specific Embodiment 3: In this embodiment, the housing 1 , the gear plate 2 and the power output shaft 5 are made of non-metallic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com