Rocker arm of an internal combustion engine valve train

A valve train, internal combustion engine technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of high cost and processing cost, low wear and guidance accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

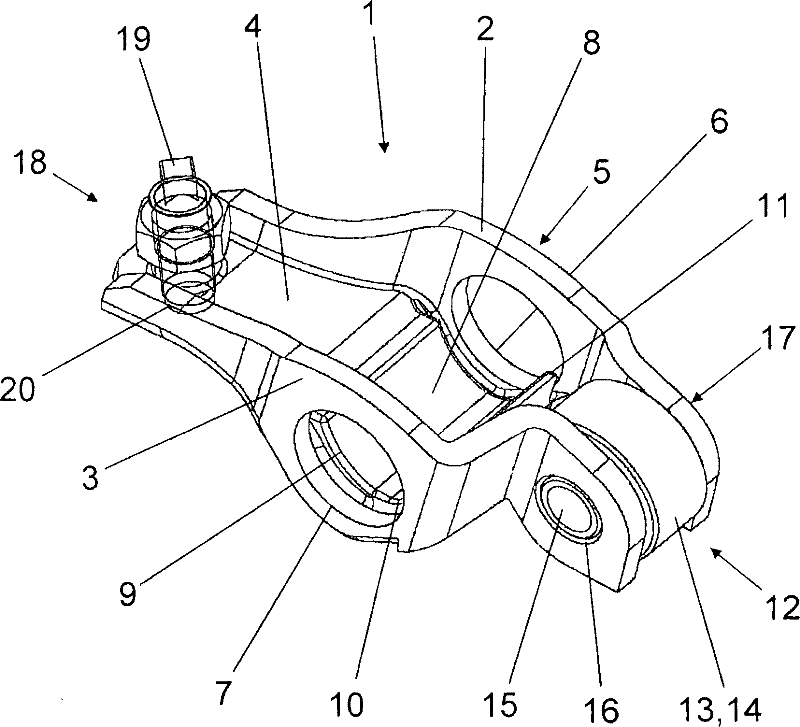

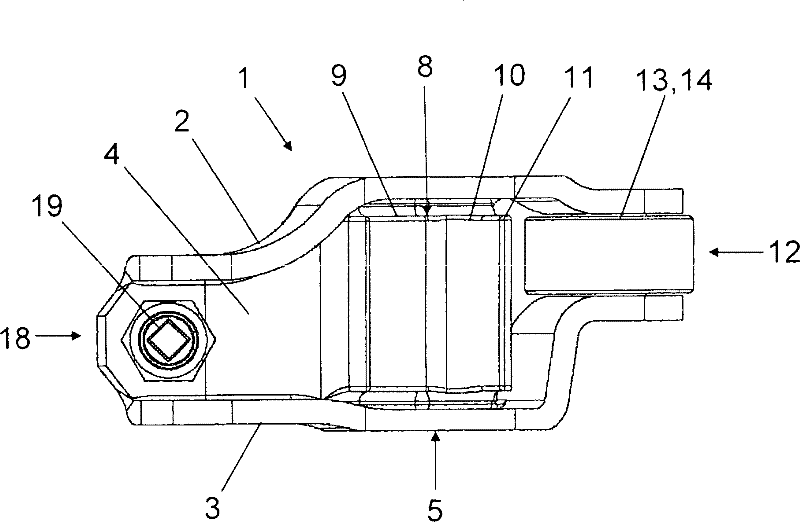

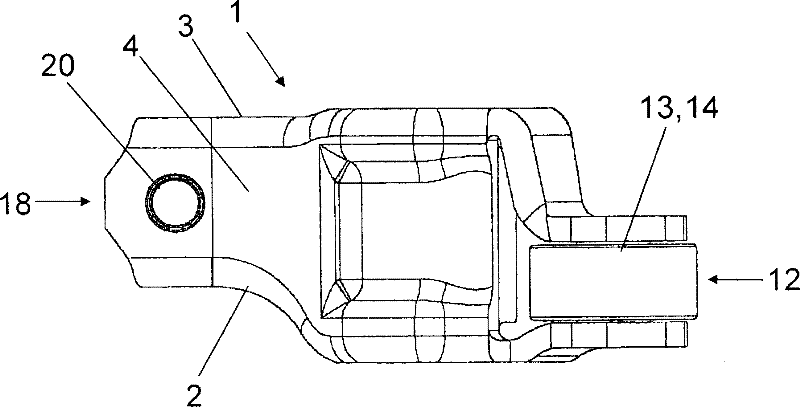

[0023] figure 1 A rocker arm of a valve train of an internal combustion engine is shown. The rocker body 1 is advantageously produced in one piece from sheet steel using suitable forming methods. It essentially has two side walls 2 , 3 connected to each other by a cross member 4 . The crossbeam 4 connects these side walls 2, 3 at the underside of the side walls, so that the rocker body 1 forms a U-like cross section. The side walls 2 , 3 have in the middle 5 two aligned bore holes 6 , 7 designed as bores for mounting the rocker arm on a shaft not shown or on an equivalent center of rotation.

[0024] On the cross member 4, a half bearing shell 8 is formed in alignment with the bores 6, 7 in the region of them. This half bearing shell 8 is used to guide the shaft or to guide a rocker arm on the shaft. The half shell 8 has a first radius 9 and a second radius 10 offset therefrom, wherein the second radius 10 opens into a bead 11 which forms the end of the cross member 4 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com