Blowing control valve

A technology for controlling valves and valve bodies, applied in the direction of valve lifts, valve details, valve devices, etc., can solve problems such as boiler blockage, boiler overheating work, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

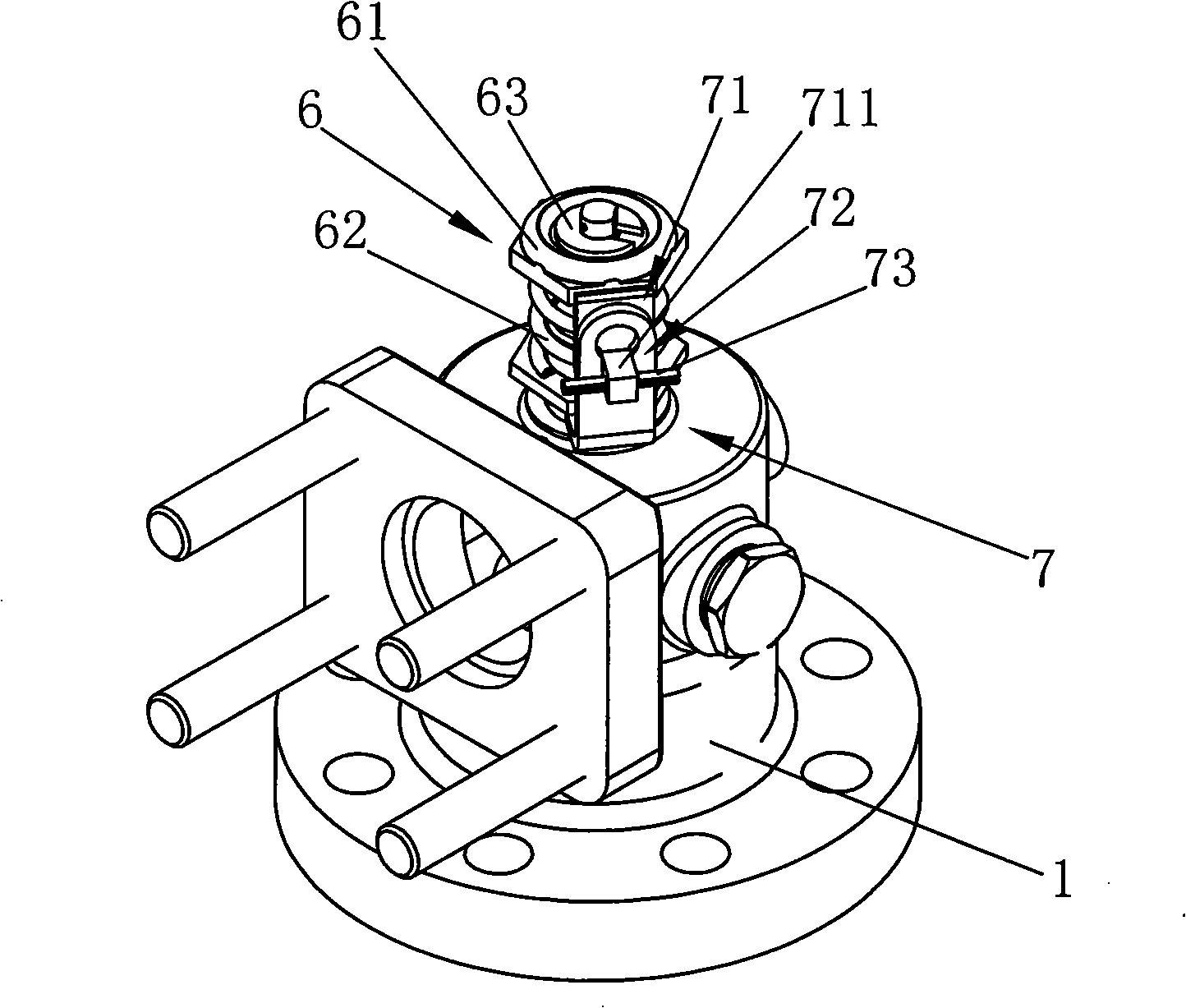

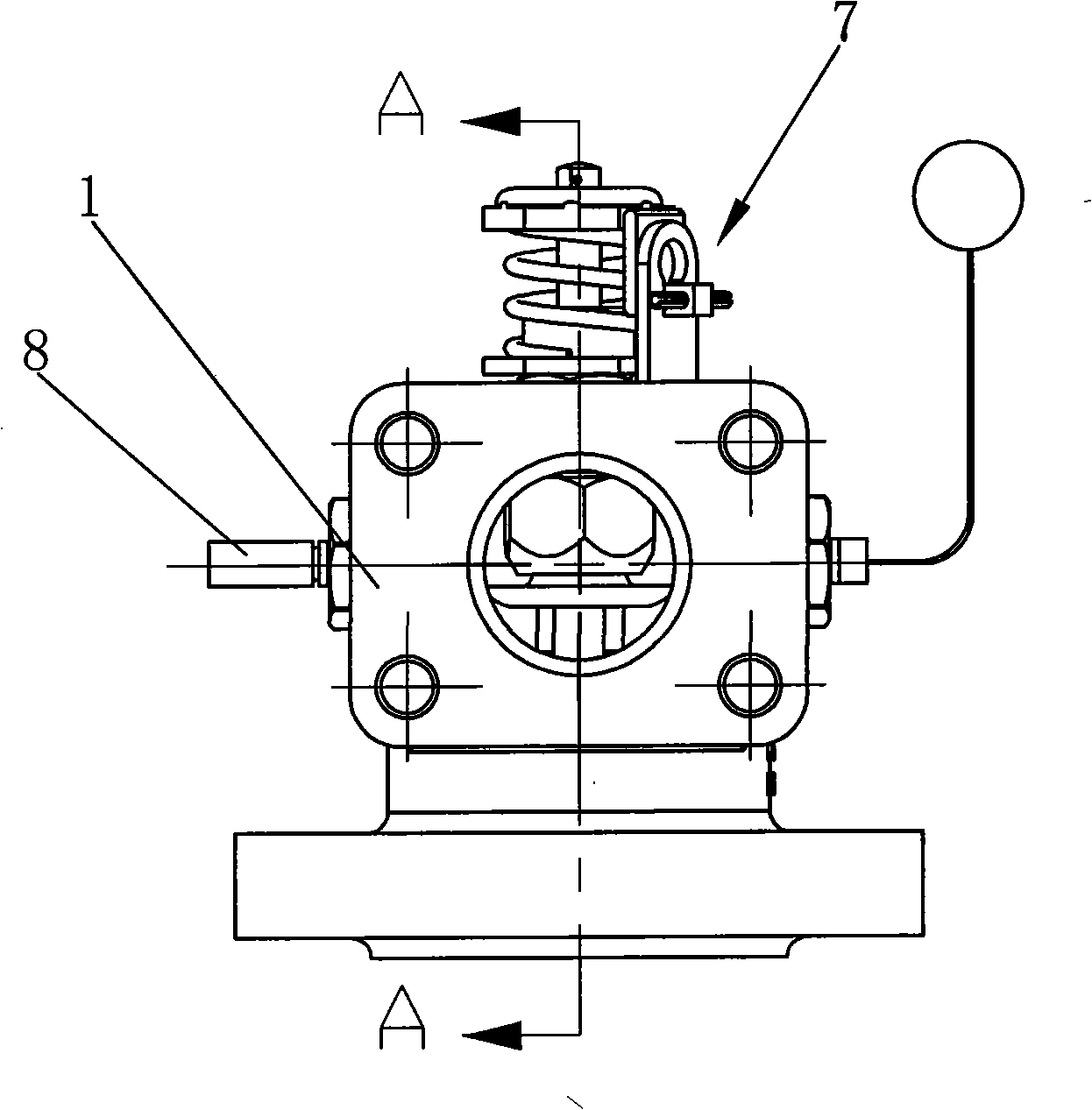

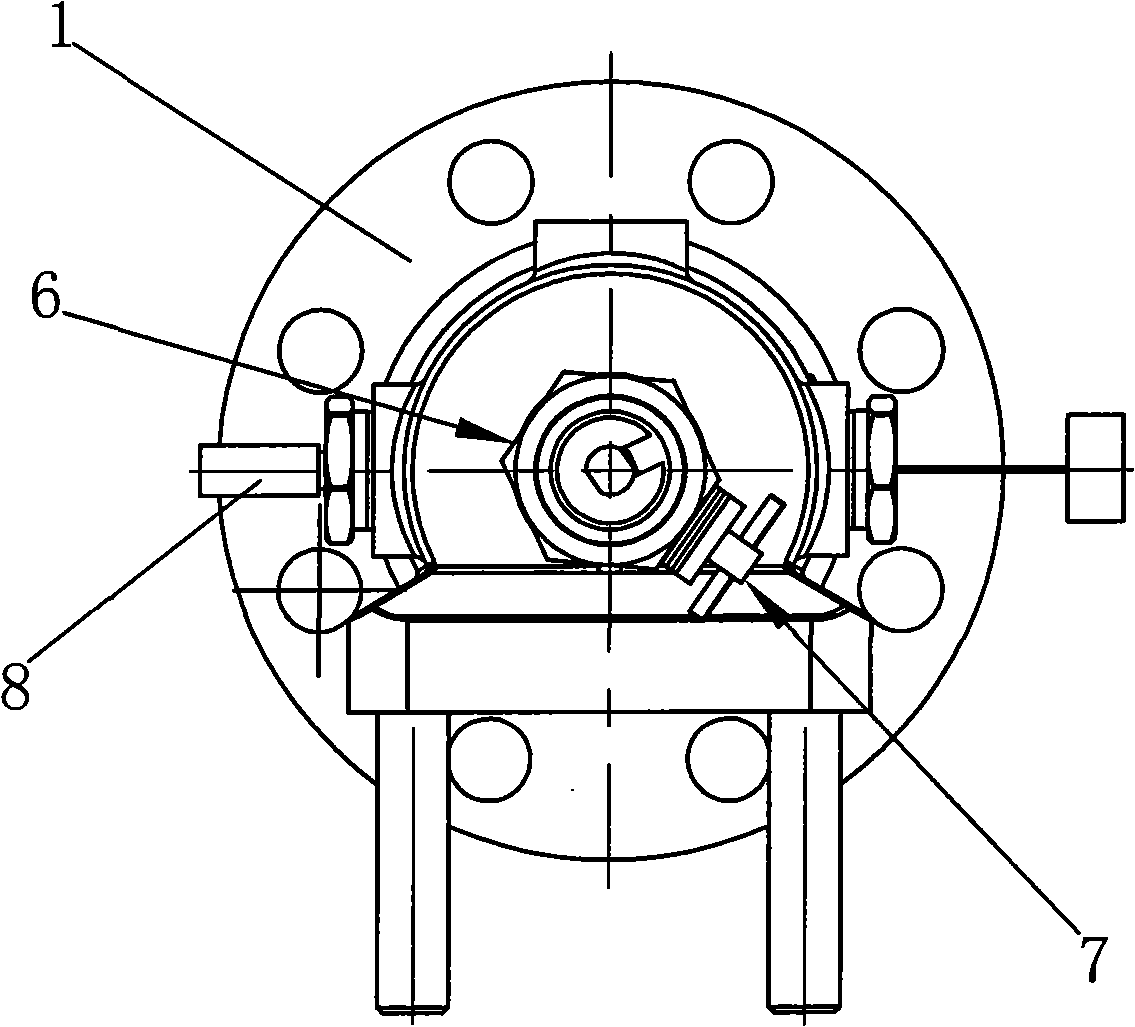

[0016] Such as figure 1 , 2 , 3, and 5, the embodiment of the present invention provides a soot blowing control valve, including a valve body 1, a valve disc 9, a valve seat 2, a valve stem 3, an adjustment ring 4, a guide sleeve 5, and a pressure adjustment device 6, The adjustment ring 4 is in the shape of "⊥", and there is a through square hole 41 in the middle. The adjustment ring 4 is located under the guide sleeve 5 and is sleeved on the valve stem 3. The lower end surface of the guide sleeve 5 corresponds to the upper end of the adjustment ring 4. Circular groove 51, the upper end of the adjustment ring 4 is set in the groove 51, and is threaded with the guide sleeve 5. Hole 41 fits. The pressure regulating device 6 includes an adjusting nut 61 and a pressure spring 62. The adjusting end 31 of the valve stem 3 is exposed from the upper end surface of the valve body 1. A through hole 611 is opened in the center of the adjusting nut 61, and the adjusting nut 61 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com