Axis external diameter length detection process and device

A detection method and detection device technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low efficiency, high work intensity, poor stability, etc., and achieve the effect of simple and convenient operation, slow solution speed and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

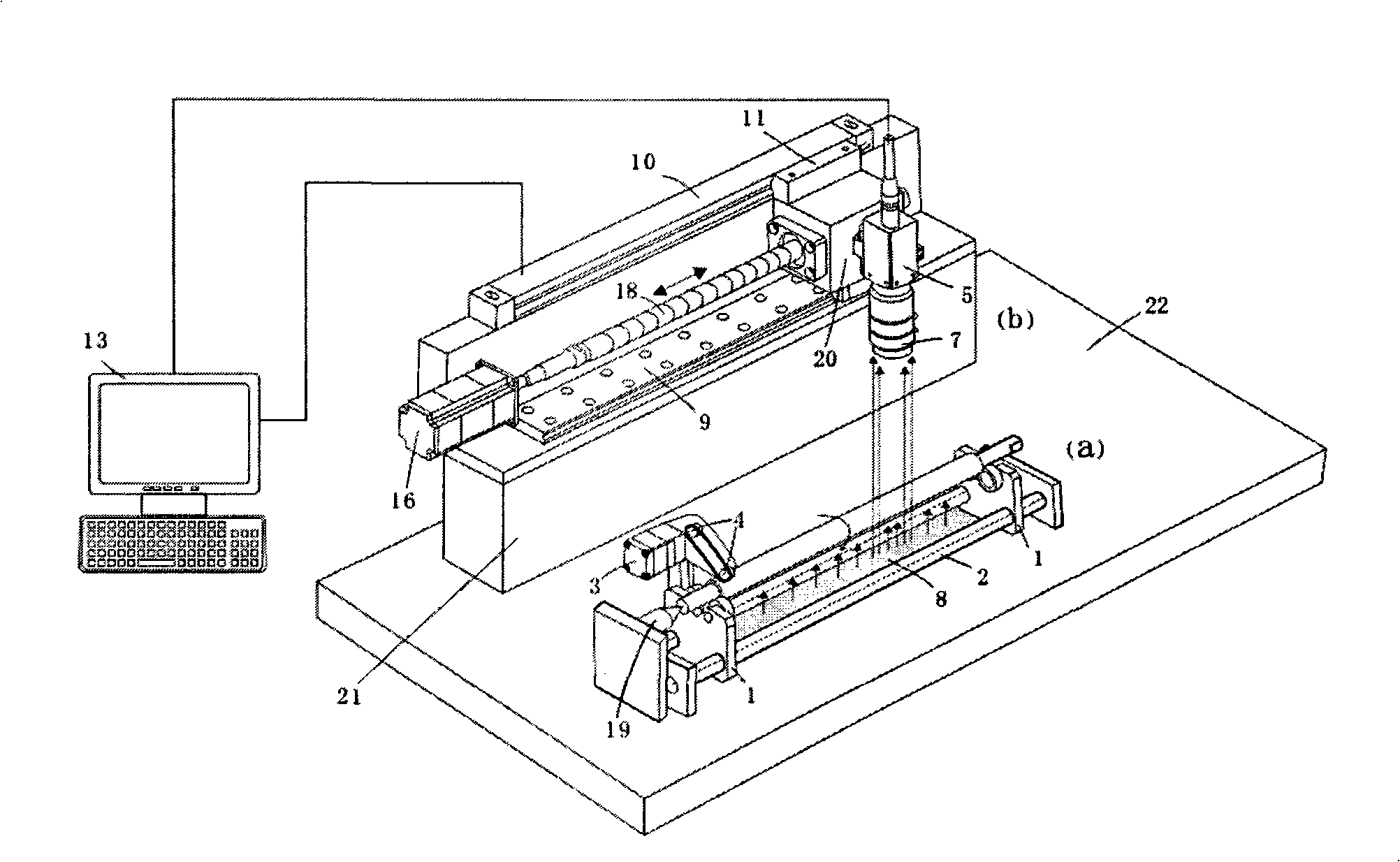

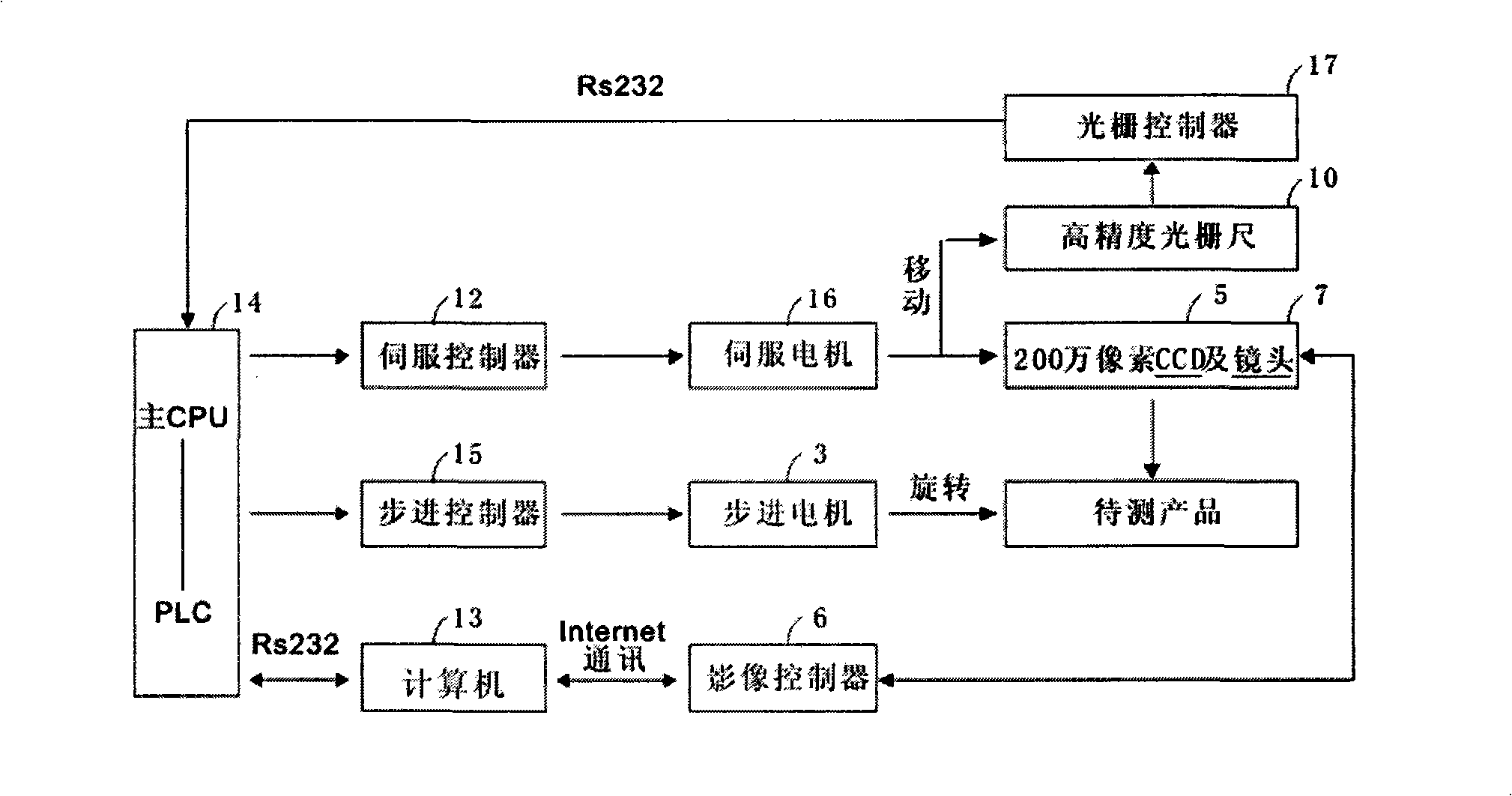

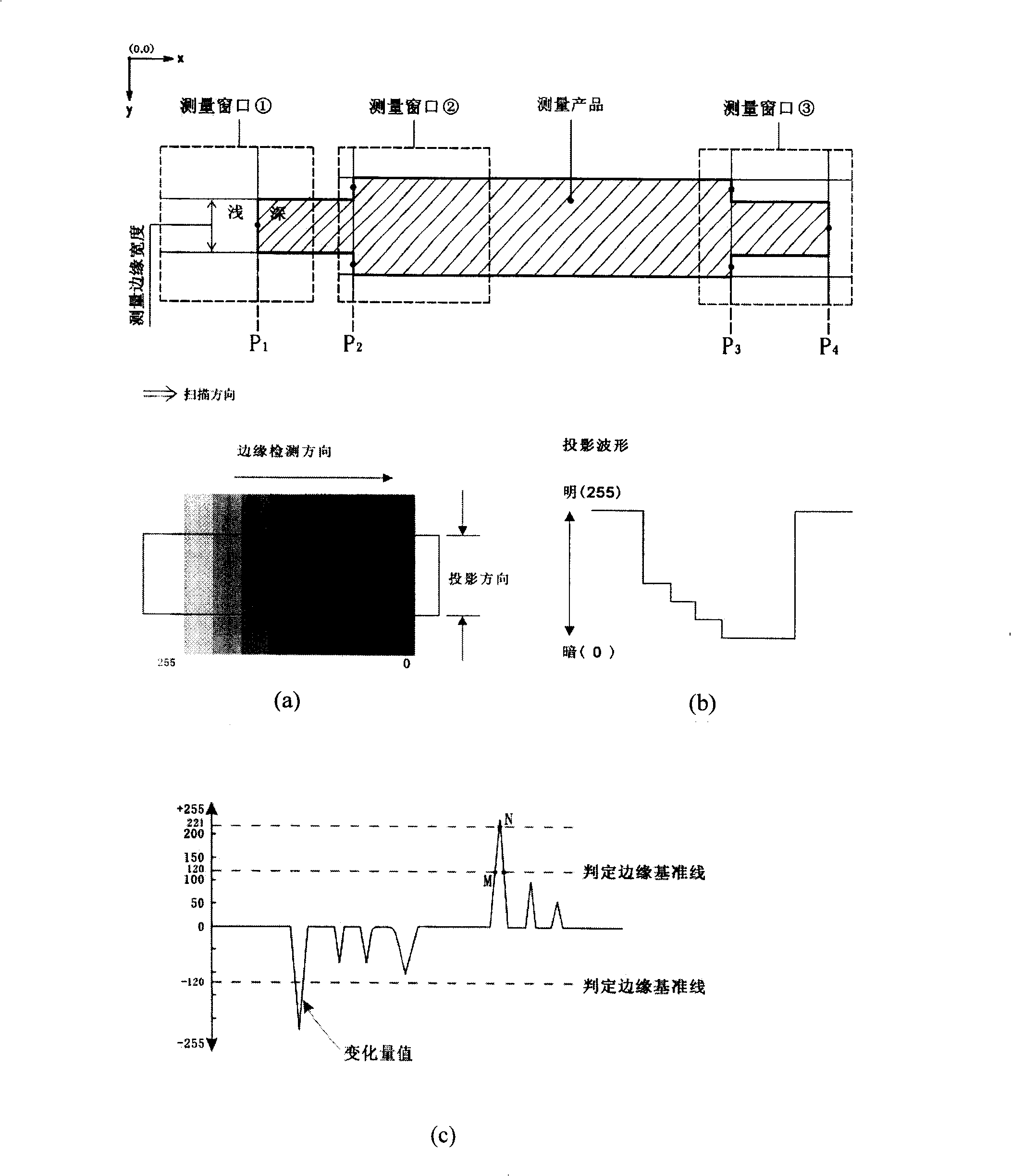

[0024] figure 1 It is a schematic structural diagram of a measuring device according to a specific embodiment of the present invention. figure 1 The middle and bottom are the product receiving platform and the shaft rotation mechanism. The product receiving platform includes two support bases 1 and two guide shafts 2. The two guide shafts 2 are installed horizontally and parallel. The two support bases 1 are installed on the left and right sides of the guide shaft 2 and can move freely along the axial direction of the guide shaft 2. In this way, the distance between the two support seats can be freely adjusted according to the length of the detection shaft. A shaft rotation drive mechanism is arranged behind the left support seat 1. The shaft rotation drive mechanism includes a stepper motor 3 and a pulley 4, which are driven by the stepper motor 3. The rotation of the pulley 4, when the pulley 4 is pressed on the shaft, drives the shaft to rotate radially. When the shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com