A method for measuring wafer liquid film middle variant in CMP process

A technology of liquid thin film and measurement method, which is applied in the direction of grinding machine parts, control of workpiece feed movement, semiconductor/solid device manufacturing, etc., can solve problems such as inability to measure, and achieve the effect of eliminating environmental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

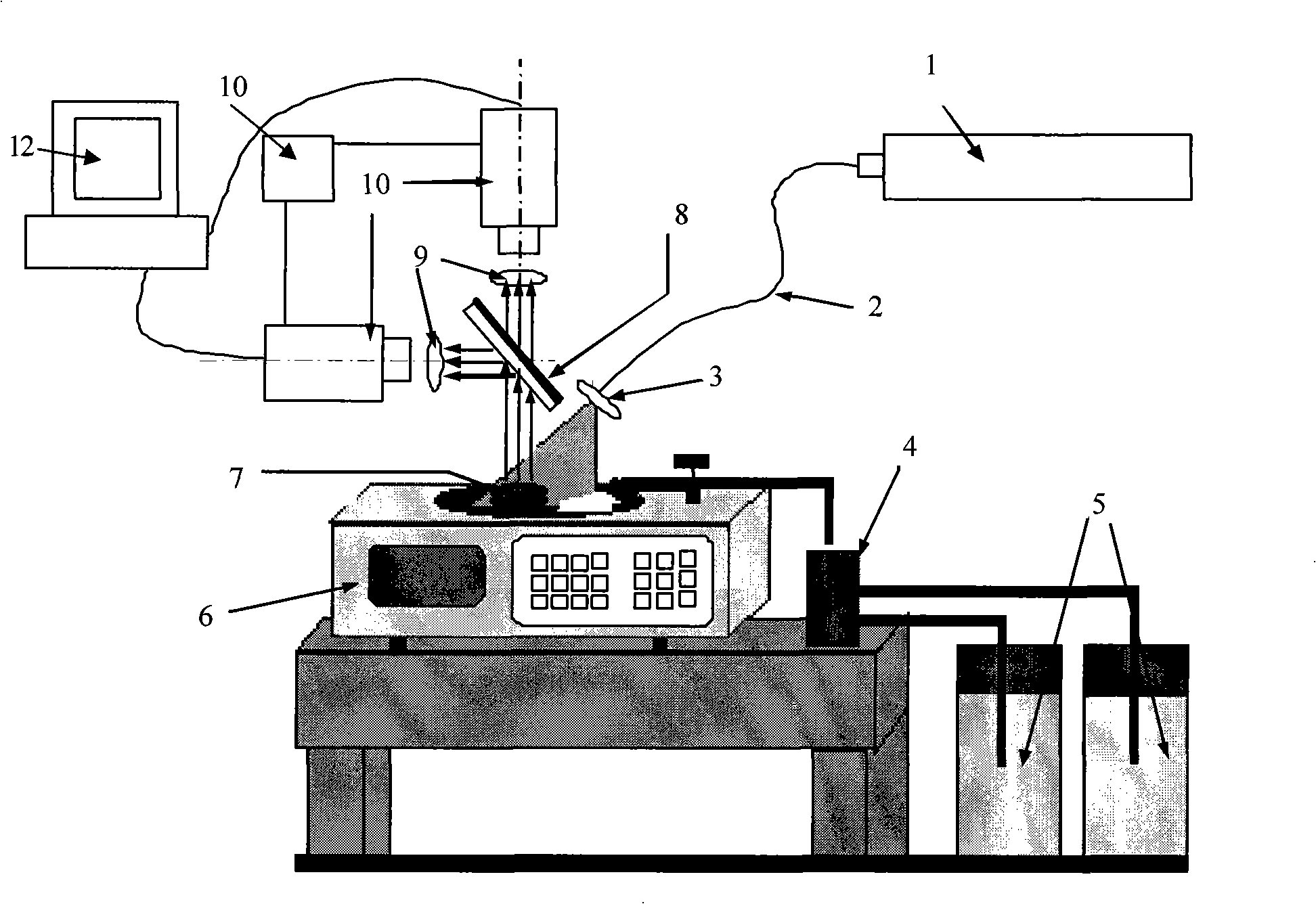

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] refer to figure 1 , a method for measuring the intermediate variable of the liquid film under the wafer in a CMP process, the method for measuring comprises the following steps:

[0025] (1), add fluorescent substance in polishing fluid 5, and polishing fluid 5 is transported between the polishing pad of polishing machine 6 and wafer 7, forms liquid thin film;

[0026] (2), turn on the laser 1 to irradiate the liquid film, and the liquid film generates fluorescence after being excited;

[0027] (3), the fluorescence emitted by the liquid film is transmitted to the camera 10 through the optical filter 9 to collect the fluorescence information;

[0028] (4), carry out image processing on the fluorescent image collected by the camera, in the computer 12, calculate the fluorescent intensity, obtain the thickness of the liquid film according to the corresponding re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com