Capacitor micro microphone chip

A microphone and capacitive technology, which is applied in the field of microphone chips, can solve the problems of low process yield, large variation in finished product quality, and difficult control of the process, and achieve the effects of reducing volume, improving yield, and reducing the cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

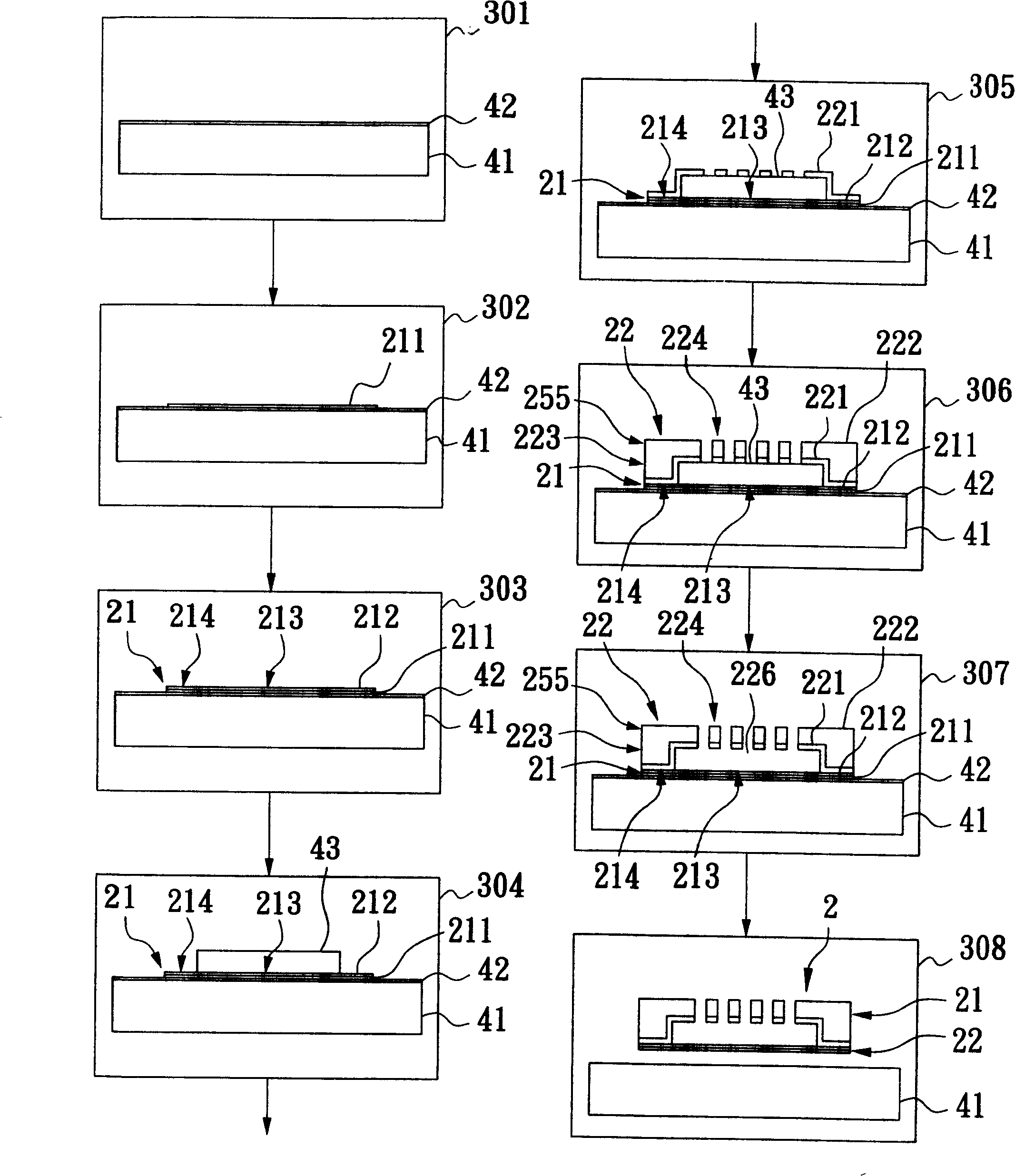

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

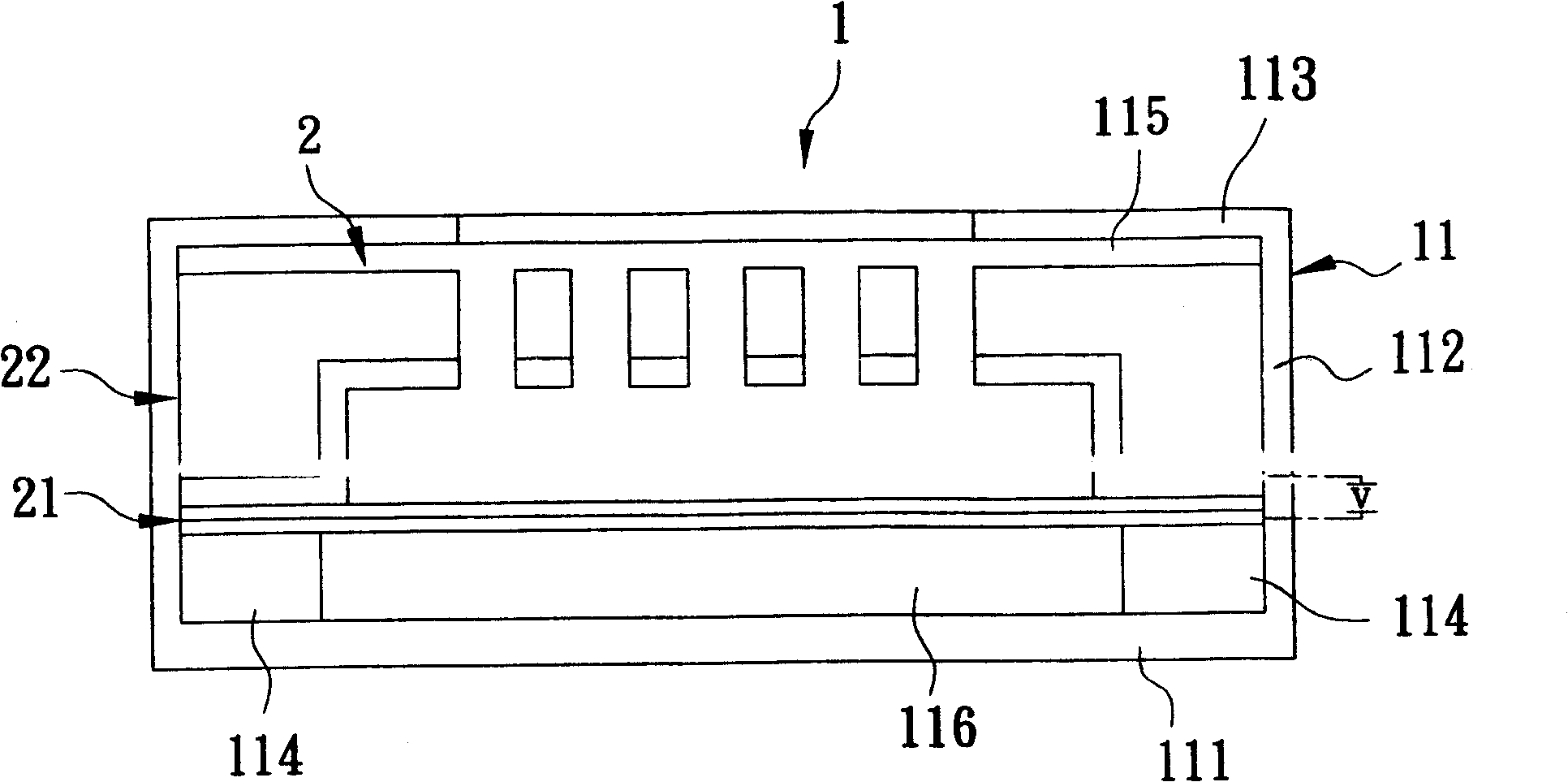

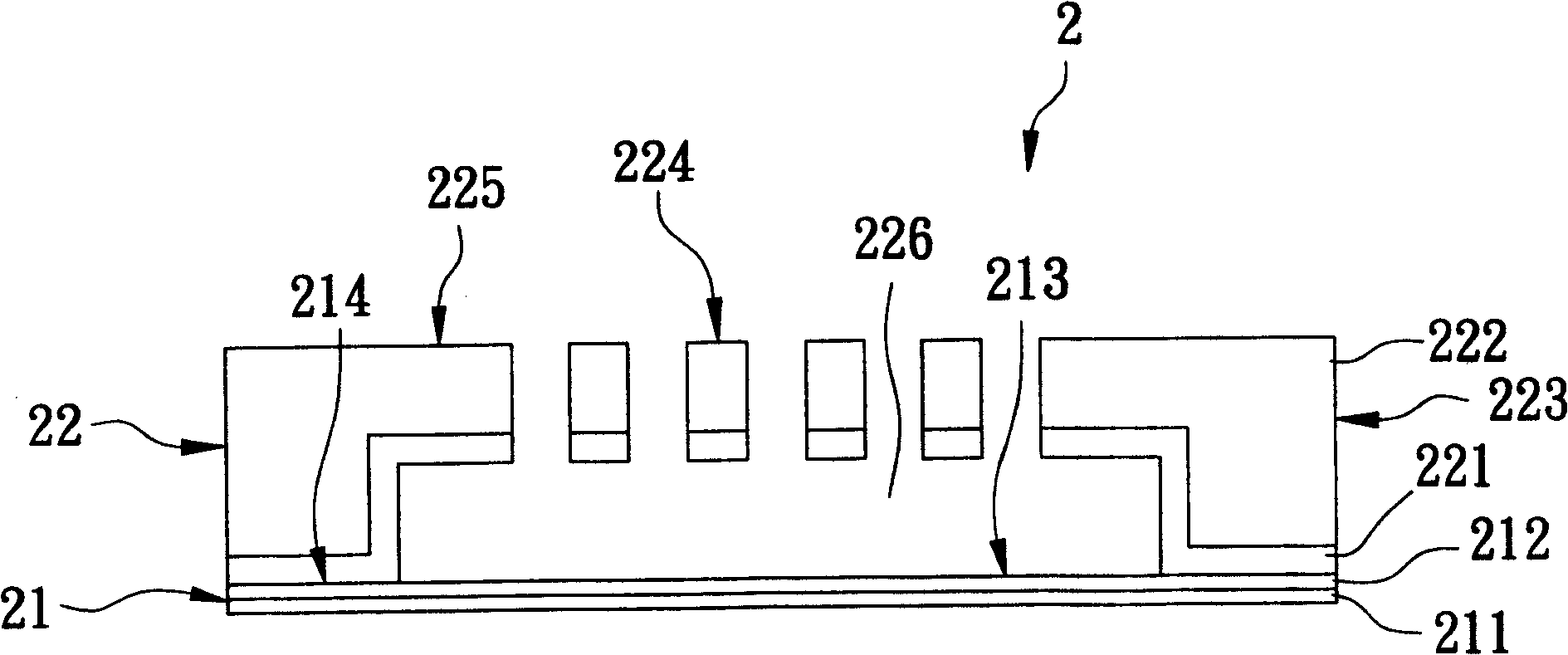

[0019] refer to figure 1 , figure 2 , a first preferred embodiment of the microphone chip of the capacitive miniature microphone of the present invention is that it can cooperate with a housing base 11 to be packaged as figure 1 The capacitive miniature microphone 1 shown is used to sense external sound energy changes.

[0020] The shell seat 1 includes a bottom wall 111, a peripheral wall 112 extending upward from the peripheral edge of the bottom wall 111, a top wall 113 connected to the top edge of the peripheral wall 112 and capable of penetrating sound energy, and a The packaging block 114 on the 111 , the bottom wall 111 , the surrounding wall 112 , and the top wall 113 jointly define a packaging space 115 for the microphone chip 2 to be accommodated.

[0021] The microphone chip 2 is manufactured using semiconductor manufacturing process, MEMS technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com