Shunting injection allocation method and shunting injection allocation machine

A dispenser and dispensing technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of reduction, high polymer molecular weight, etc., and achieve enhanced oil recovery, small shearing effect, The effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

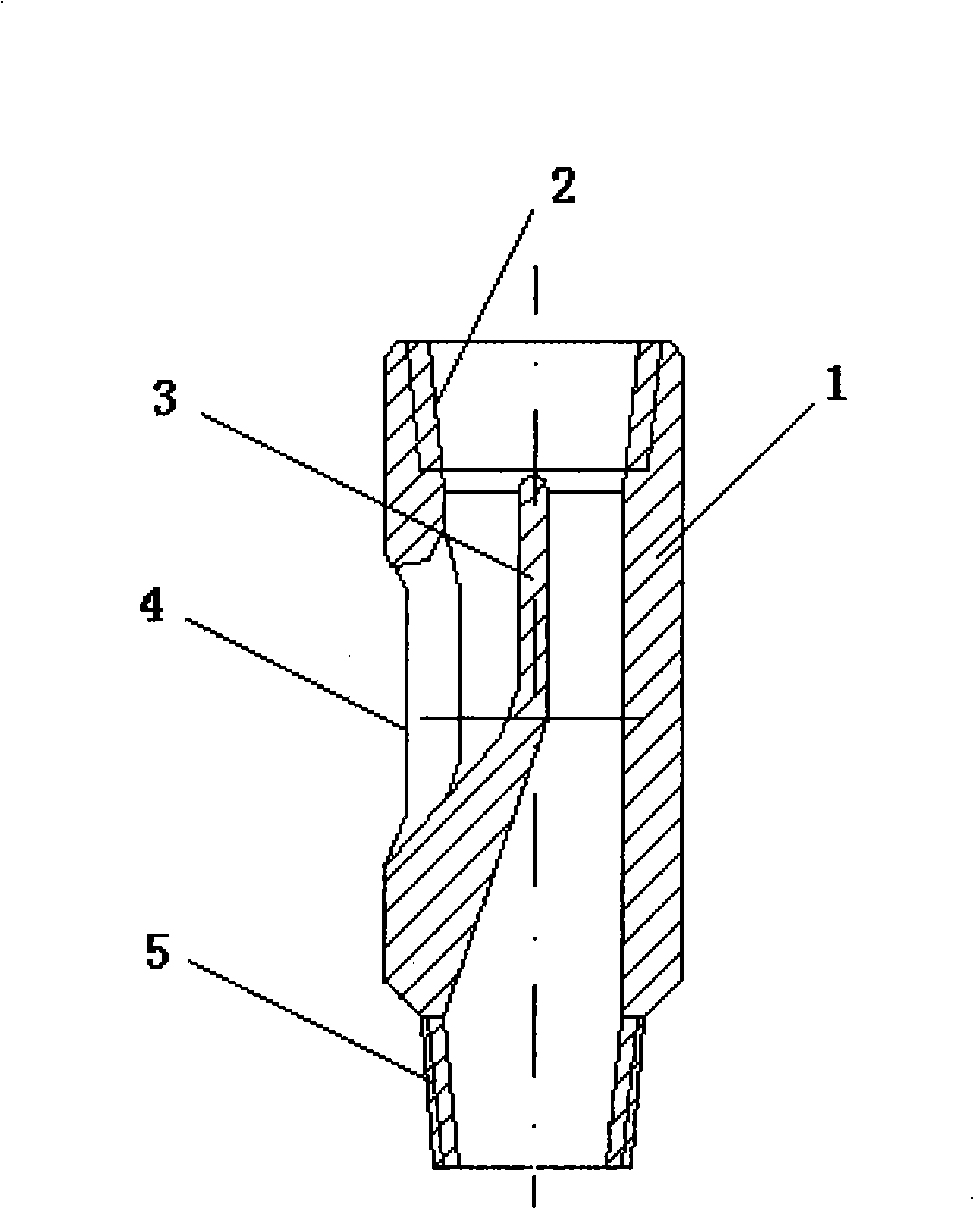

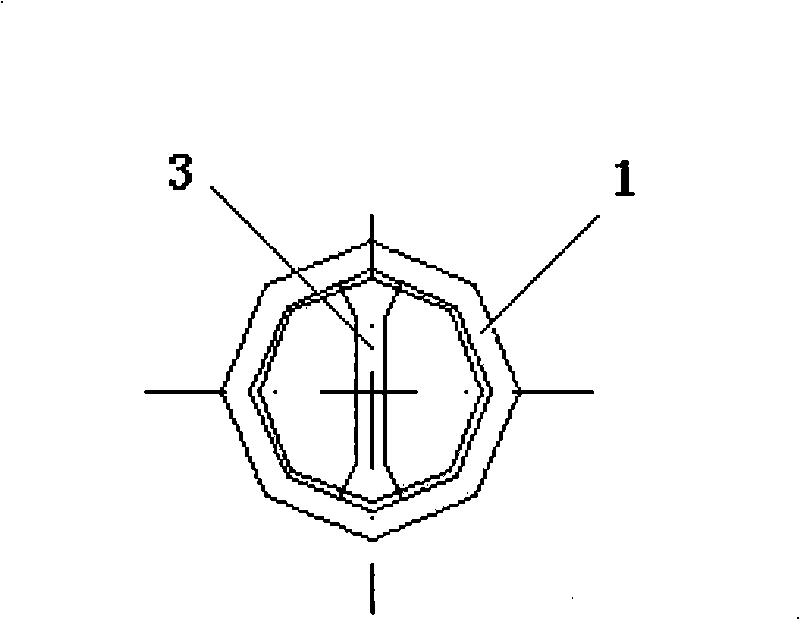

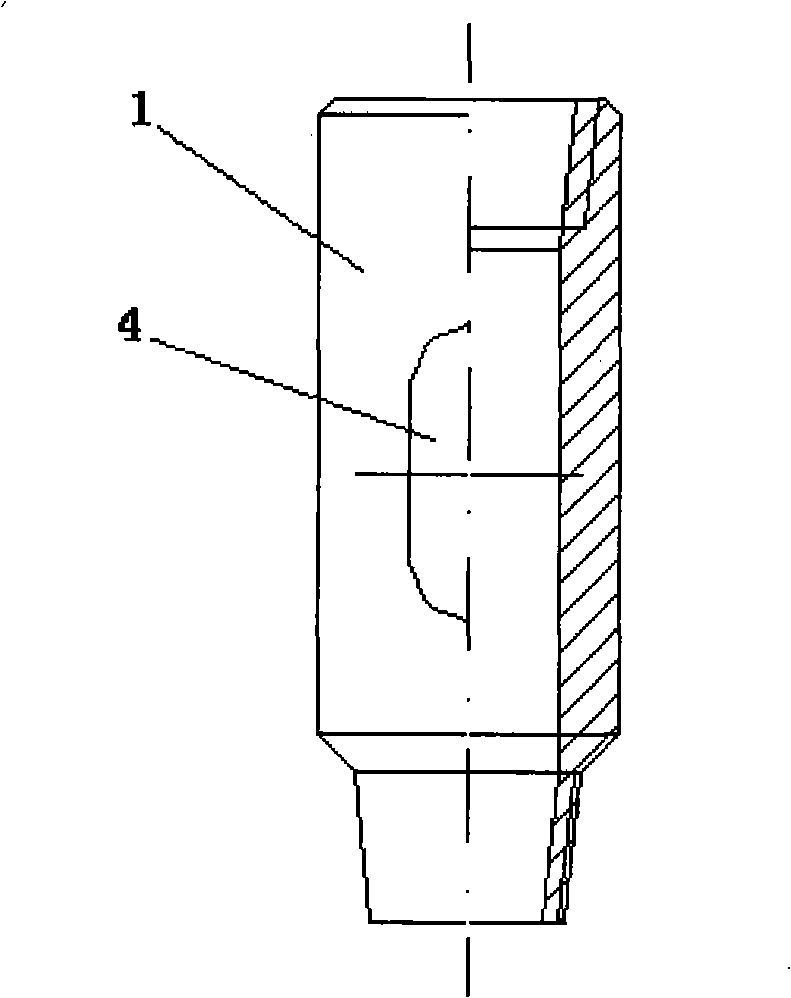

[0013] Such as Figure 1~3 As shown, the present invention includes a cylindrical dispenser body 1, a tapered internal thread interface 2 is provided on the upper part of the dispenser body 1, and a smooth-surface shunt barrier 3 is provided at the lower part of the internal thread interface 2. The lower part of the divider barrier 3 is inclined to one side of the inner wall of the dispenser body 1 and smoothly connected with it, thereby dividing the inner cavity of the dispenser body 1 into two parts, one part of which is connected to the outlet 4 on the side of the dispenser body 1 The other part communicates with the tapered external thread interface 5 provided at the lower part of the dispenser body 1 .

[0014] Such as Figure 4 As shown, when the present invention is used, the internal thread interface 2 on the upper part of the dispenser body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com