Sintered oil-impregnated bearing and manufacturing method thereof

A bearing and bearing hole technology, applied in the direction of bearings, shafts, bearings, bearing components, etc., can solve the problems of sand sticking and supply, and achieve the effect of lowering the friction coefficient and improving the sliding characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

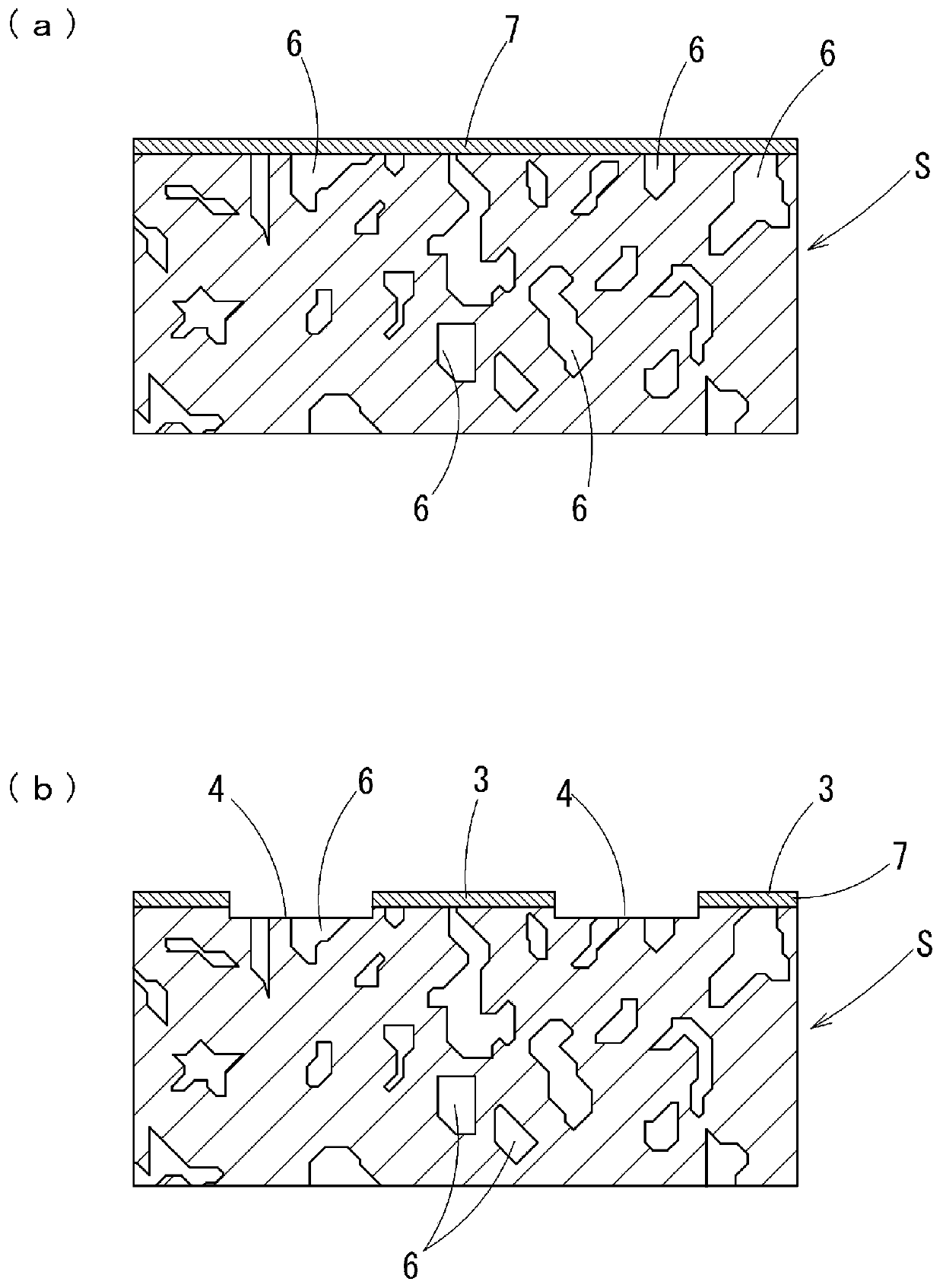

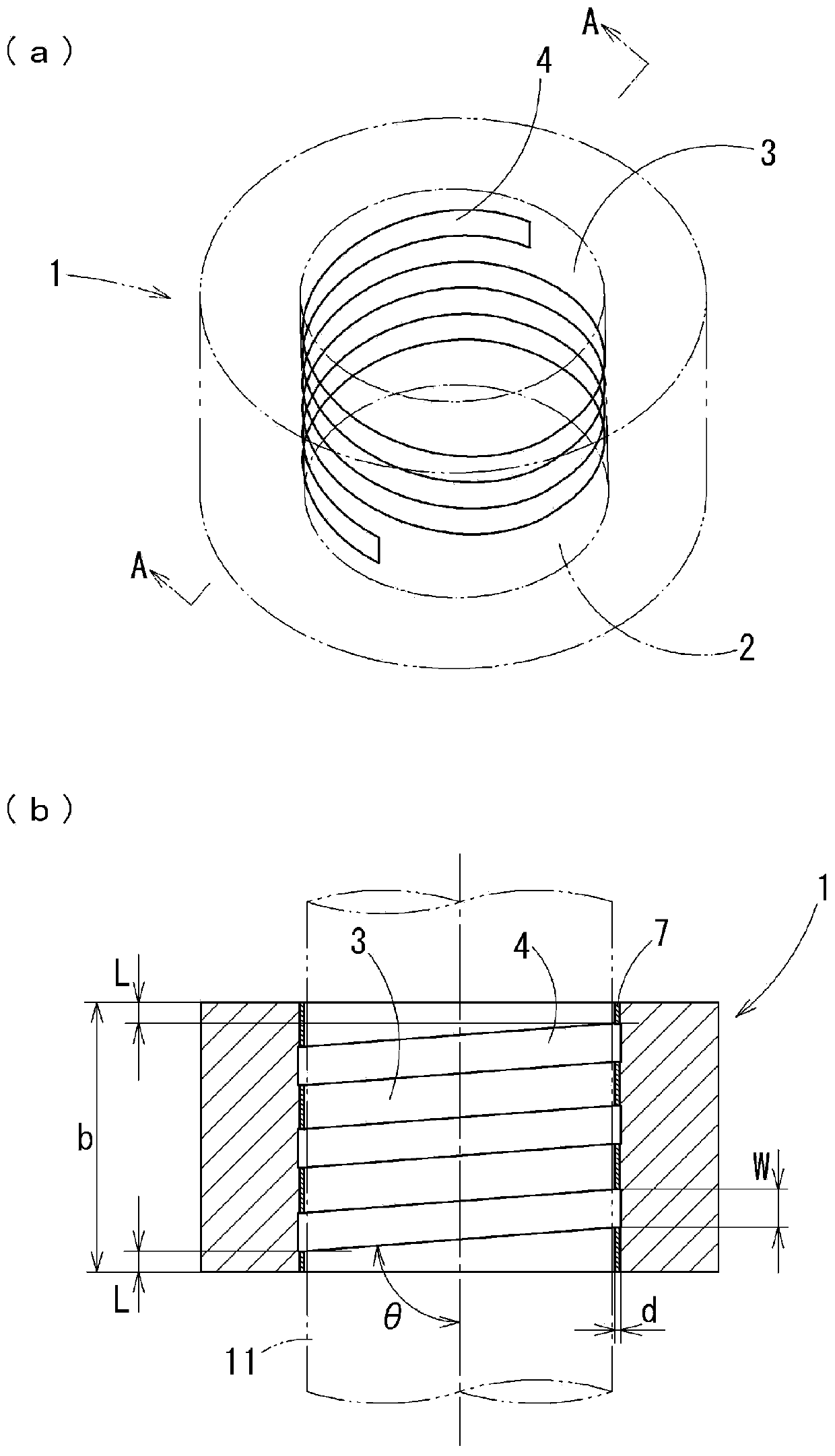

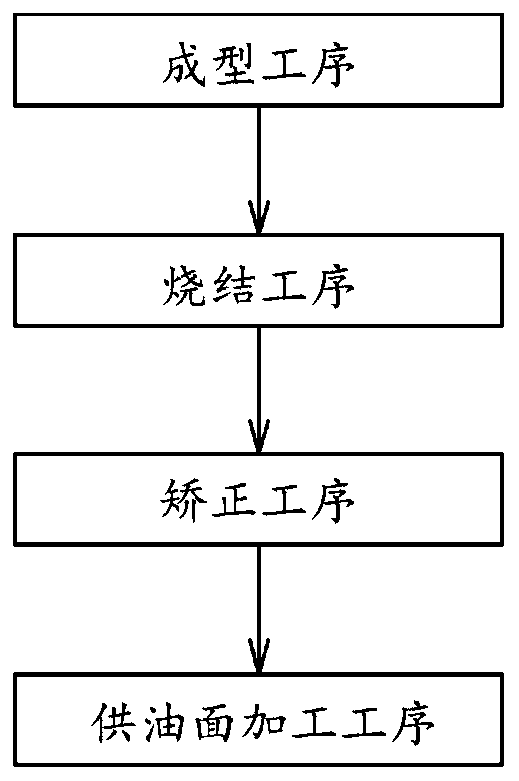

[0054] The test results conducted to verify the effects of the present invention will be described. As the raw material powder used in the test, iron-copper-based powder in which iron, copper, tin (low melting point alloy), graphite, etc. were mixed in a predetermined ratio was used. As its mixing ratio, copper powder was adjusted to 50% by mass, tin powder to 2% by mass, copper-phosphorus powder to 5% by mass, copper-zinc powder to 10% by mass, solid lubricants such as graphite to 0.5% by mass, and the remaining Part of it is iron powder. This raw material powder was compression-molded and sintered at a temperature of 950° C., followed by a straightening process, and a concave portion was formed on the inner peripheral surface of the bearing hole by cutting. Both assume that the length of the bearing is 8 mm, and the inner diameter of the bearing hole (of the sliding surface) is 8 mm.

[0055] For the obtained bearing, the inner peripheral surface of the bearing hole was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com