An Electroplated Diamond Tool for Drilling Fiber Reinforced Composite Materials

A technology of electroplating diamond and composite materials, which is applied to lathe tools, drilling accessories, drilling/drilling equipment, etc., can solve the problems of easy delamination, tearing and burrs, and reduce the friction coefficient , increase strength, increase the effect of chip removal and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

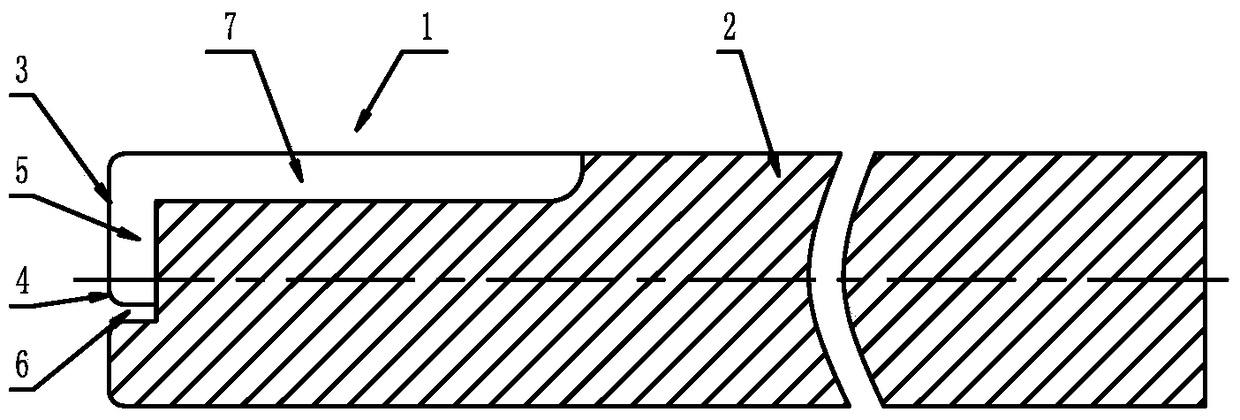

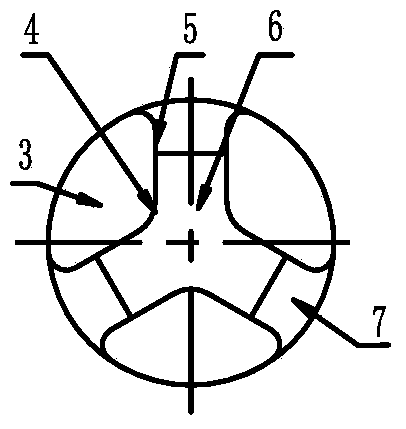

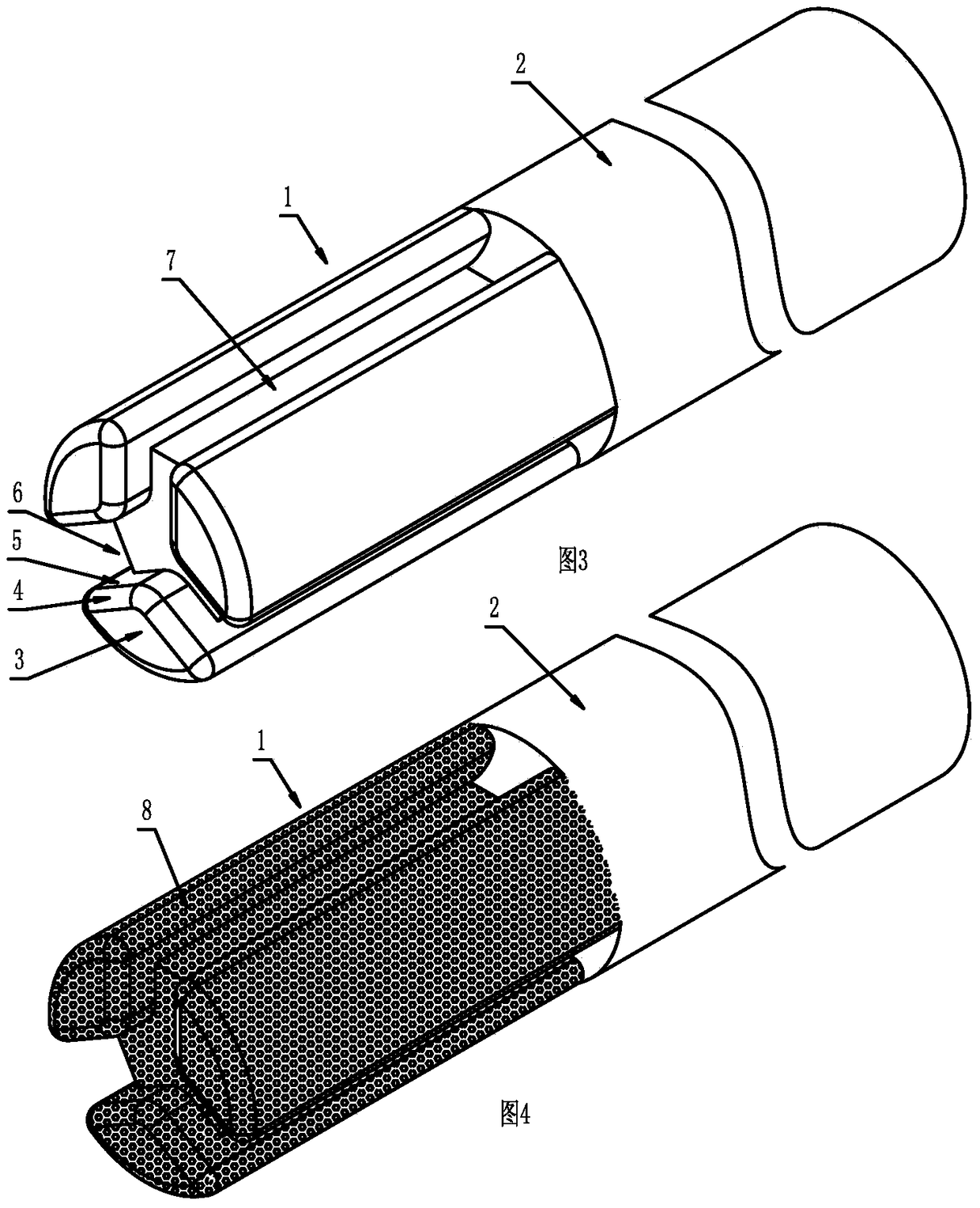

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0023] Such as figure 1 and figure 2 As shown, the present invention is a kind of electroplated diamond cutter for fiber-reinforced composite material drilling, comprising a cylindrical cutter bar 2, the front end of the cutter bar 2 is provided with a cutter head 1 with diamond particles 8 electroplated on the surface, the cutter head The length of 1 can be 15-25 mm. The cutter head 1 includes a plurality of cutting parts and a plurality of chip removal grooves 7 uniformly distributed in the radial direction. The cutting parts and chip removal grooves 7 are arranged alternately in the circumferential direction. The surfaces are all part of the same cylindrical surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com