Hydraulic cylinder and production method thereof

A manufacturing method and technology of a hydraulic cylinder, applied in the field of hydraulic machinery, can solve the problems of high manufacturing cost, large cylinder oil cavity, thick piston rod, etc., and achieve the effects of reducing oil storage, reducing oil tank and reducing hydraulic pump flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

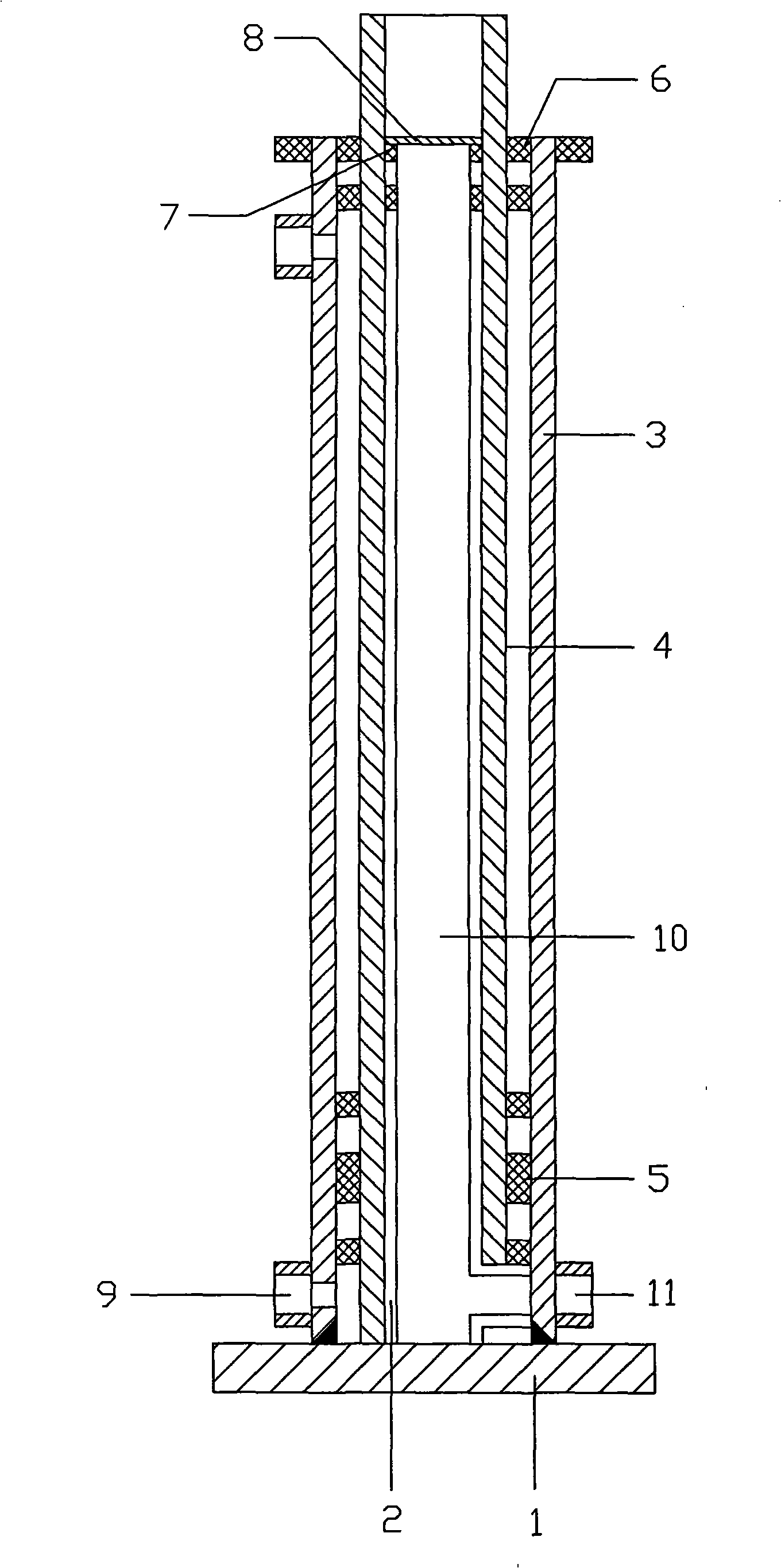

Embodiment 1

[0012] To make a hydraulic cylinder with a stroke of 9 meters and a capacity of 5 tons:

[0013] 1. Make a hydraulic cylinder base with a diameter of 140mm and a thickness of 30mm;

[0014] Make a positioning tube with a length of 9000mm, 10mm behind the wall, an outer diameter of 60mm, and an inner diameter of 40mm. The area of the outer diameter circle is 28.26 square centimeters, and the area of the inner diameter circle is 12.56 square centimeters;

[0015] Manufacture a hydraulic cylinder cylinder with a length of 9000mm, a wall back of 10mm, an outer diameter of 110mm, and an inner diameter of 90mm, and its inner diameter circle area is 63.585 square centimeters;

[0016] Manufacture a hydraulic piston tube with a length of 9100mm, a wall back of 10mm, an outer diameter of 80mm, and an inner diameter of 60mm, with an outer diameter circle area of 50.24 square centimeters and an inner diameter circle area of 28.26 square centimeters;

[0017] Make a piston with a...

Embodiment 2

[0020] To make a hydraulic cylinder with a stroke of 9 meters and a capacity of 2 tons:

[0021] 1. Make a hydraulic cylinder base with a diameter of 130mm and a thickness of 30mm;

[0022] Make a positioning tube with a length of 9000mm, 10mm behind the wall, an outer diameter of 60mm, and an inner diameter of 40mm. The area of the outer diameter circle is 28.26 square centimeters, and the area of the inner diameter circle is 12.56 square centimeters;

[0023] Manufacture a hydraulic cylinder cylinder with a length of 9000mm, a wall back of 10mm, an outer diameter of 100mm, and an inner diameter of 80mm, and its inner diameter circle area is 50.24 square centimeters;

[0024] Manufacture a hydraulic piston tube with a length of 9100mm, a wall back of 6mm, an outer diameter of 72mm, and an inner diameter of 60mm. The outer diameter circle area is 40.69 square centimeters, and the inner diameter circle area is 28.26 square centimeters;

[0025] Make a piston with a diamete...

Embodiment 3

[0029] Make a hydraulic cylinder with a stroke of 3 meters and a load of 0.5 tons:

[0030] 1. Make a hydraulic cylinder base with a diameter of 100mm and a thickness of 30mm;

[0031] Make a positioning column with a length of 3000mm and a diameter of 30mm, and its bottom circle area is 7.06 square centimeters;

[0032] Manufacture a hydraulic cylinder cylinder with a length of 3000mm, a wall back of 10mm, an outer diameter of 90mm, and an inner diameter of 70mm, and its inner diameter circle area is 38.465 square centimeters;

[0033] Manufacture a hydraulic piston tube with a length of 3100mm, a wall back of 6mm, an outer diameter of 62mm, and an inner diameter of 50mm. The outer diameter circle area is 30.18 square centimeters, and the inner diameter circle area is 19.625 square centimeters;

[0034] Make a piston with a diameter of 70mm with a sealing ring inlaid with the hydraulic piston tube.

[0035] 2. Connect the positioning column 2 vertically and parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com