Electric-controlled shifting mechanism for engineering machinery

A shifting mechanism and engineering machinery technology, applied in the direction of mechanical equipment, engine components, engine sealing, etc., can solve the problems of large operating space of the shift handle, operator tension and fatigue, and difficulty in assembly and adjustment, and achieve easy and stable Increased effects of shift action, reduction of fuel economy improvement, and reduction of power-related pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

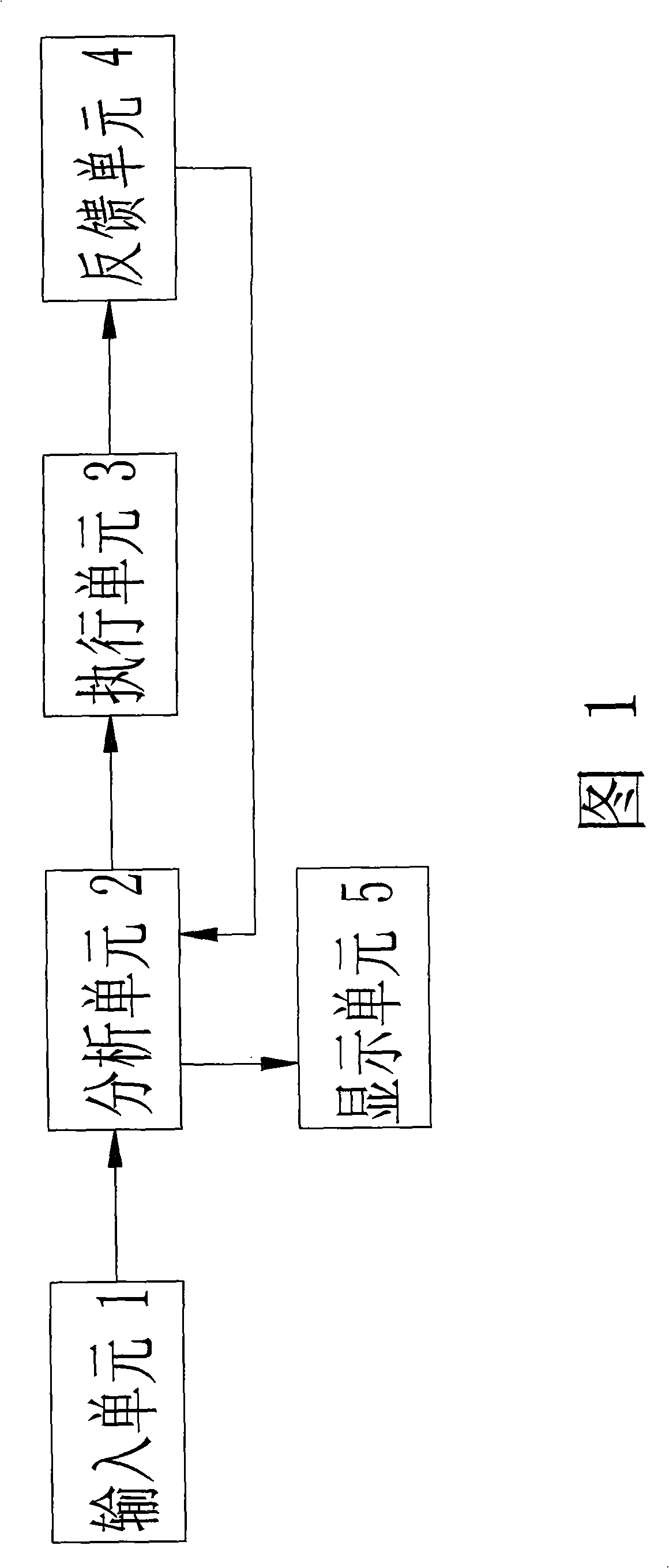

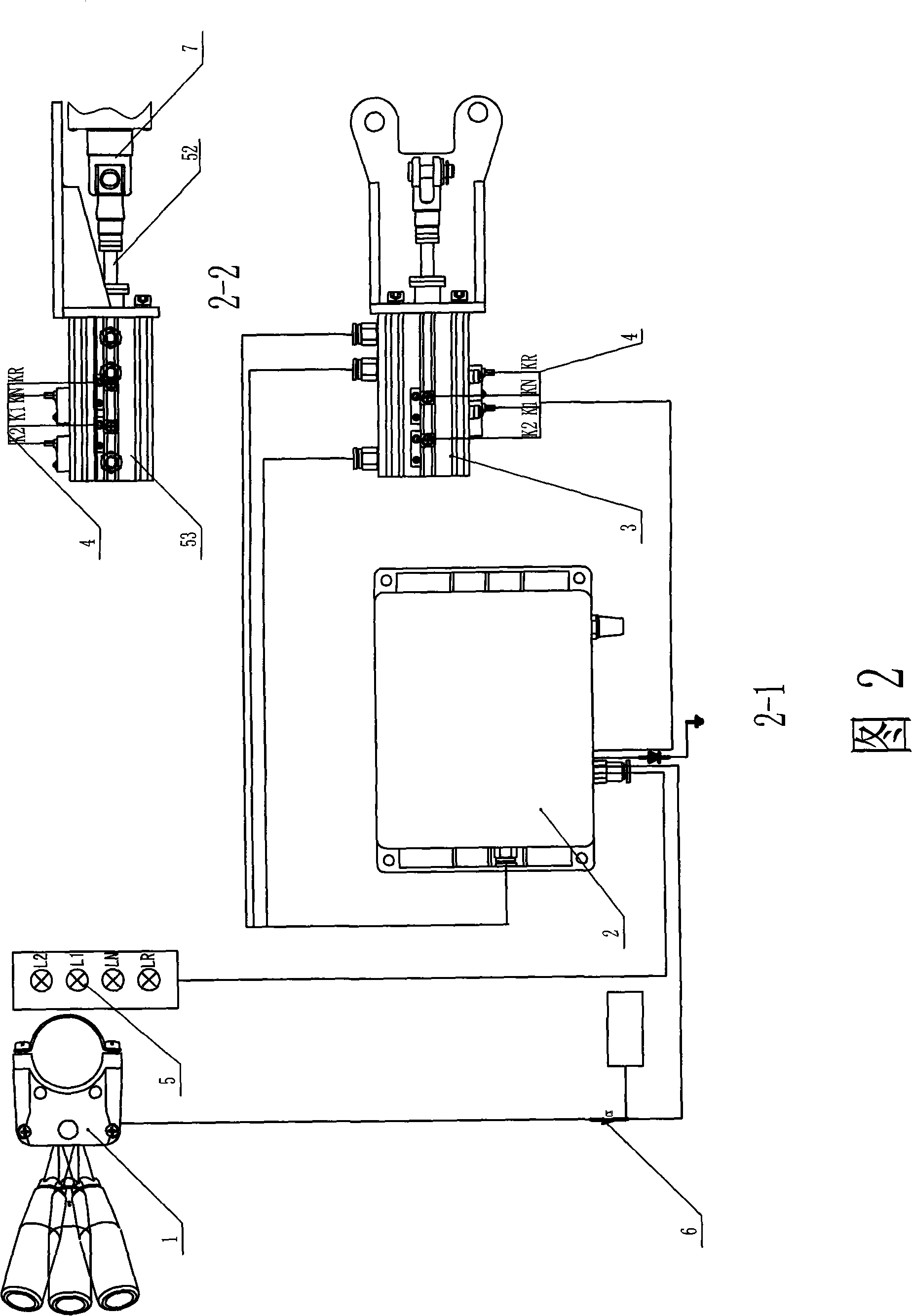

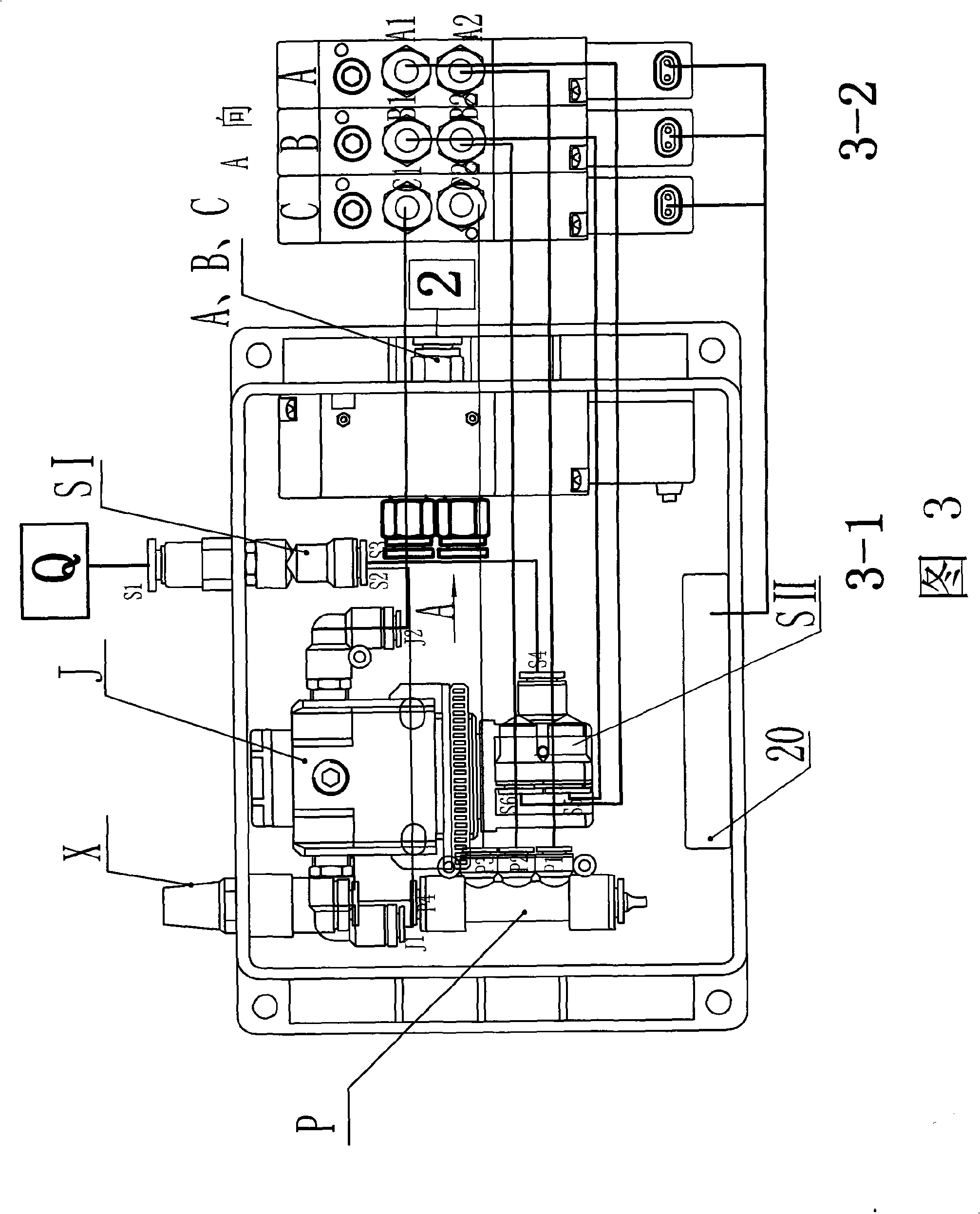

[0026] As shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 As shown: the electronically controlled shift mechanism for construction machinery is mainly composed of input unit 1, analysis unit 2, execution unit 3, and feedback unit 4 connected in sequence. The input unit 1 is connected to the steering column 10 of the cab, and the automatic reset type combined handle 11 is collected to give a shift signal and sent to the analysis unit 2; a safety protection switch 6 is also provided between the input unit 1 and the analysis unit 2 to prevent the vehicle from Misoperation after stopping; the analysis unit 2 processes the input shift signal and provides execution signals for the execution unit 3 according to the position signal fed back by the feedback unit 4; the execution unit 3 executes various execution instructions given by the analysis unit 2, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com