On-line automatic cleaning device for electro-chemistry glass electrode

A glass electrode and automatic cleaning technology, which is applied in the field of electrochemical detection, can solve problems such as troublesome and inability to realize continuous detection, and achieve the effects of reliable use, strong cleaning effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

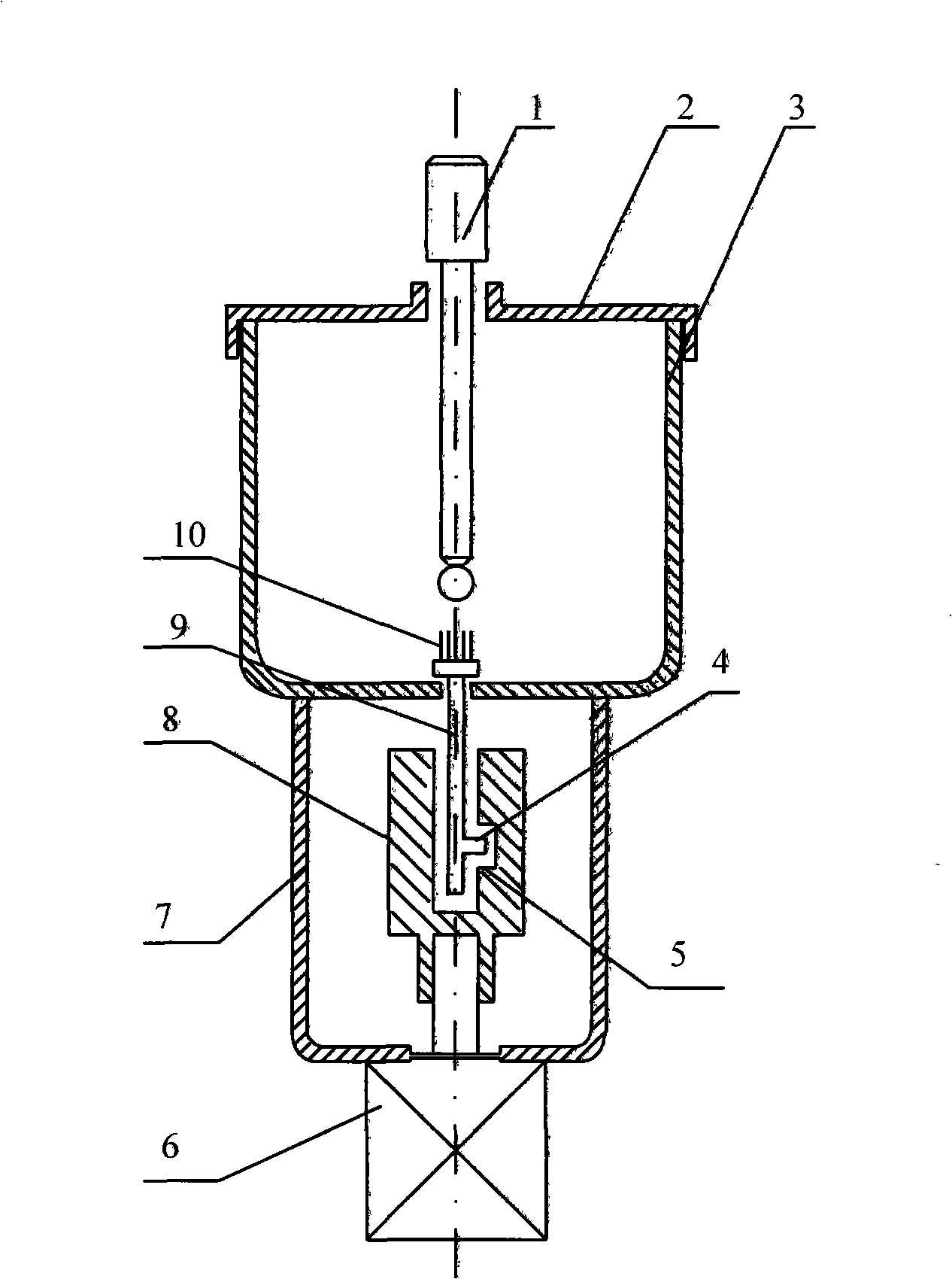

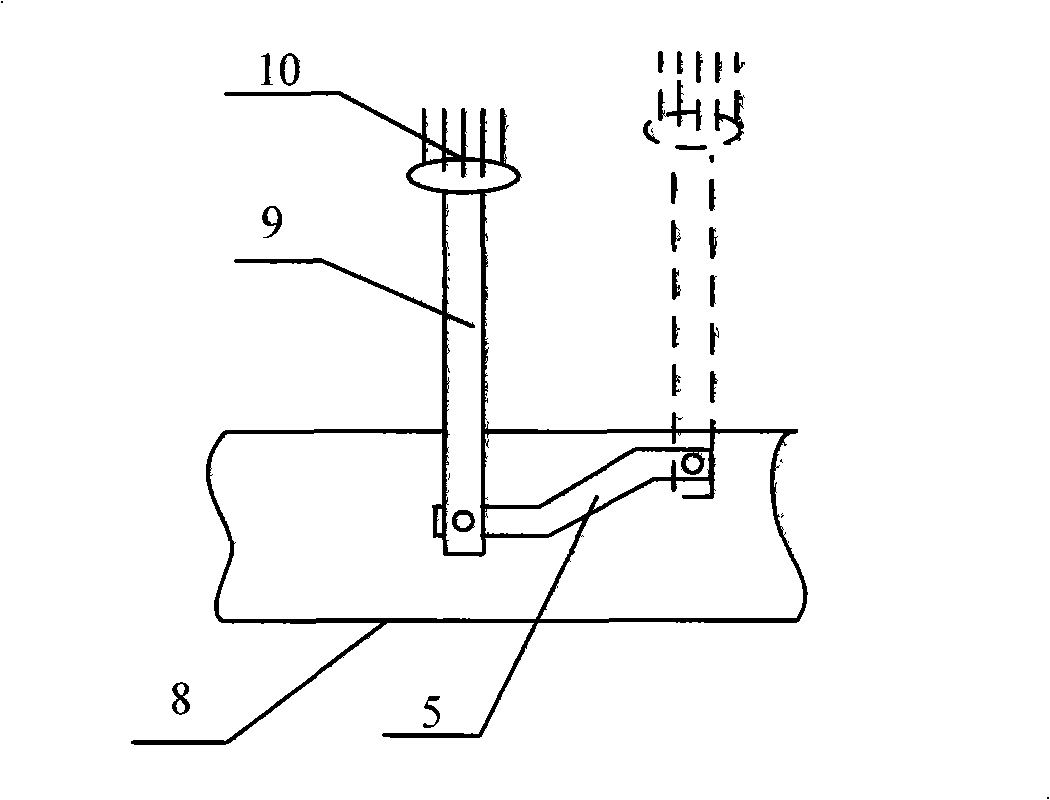

[0009] Such as figure 1 with figure 2 As shown, an online automatic cleaning device for electrochemical glass electrodes. The present invention includes a round cup-shaped cleaning seat 3, an end cover 3 is arranged on the top of the cleaning seat 3, and a cleaning port is opened in the center of the end cover 3. The bottom of cleaning seat 3 is connected with the top of round cup-shaped support 7, and the bottom of support 7 is provided with motor 6, and the power output shaft of motor 6 is fixedly connected with sliding sleeve 8. The sliding sleeve 8 is cylindrical, and the inner side wall is obliquely provided with a chute 5. When the inner side is expanded, the chute 5 becomes slope-like. The push rod 9 passes through the central through hole at the bottom of the cleaning seat 3 and is set in the inner cavity of the sliding sleeve 8, the top of the push rod 9 is fixed with a brush 10, the lower part of the push rod 9 is provided with a protrusion 4, and the protrusion 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com