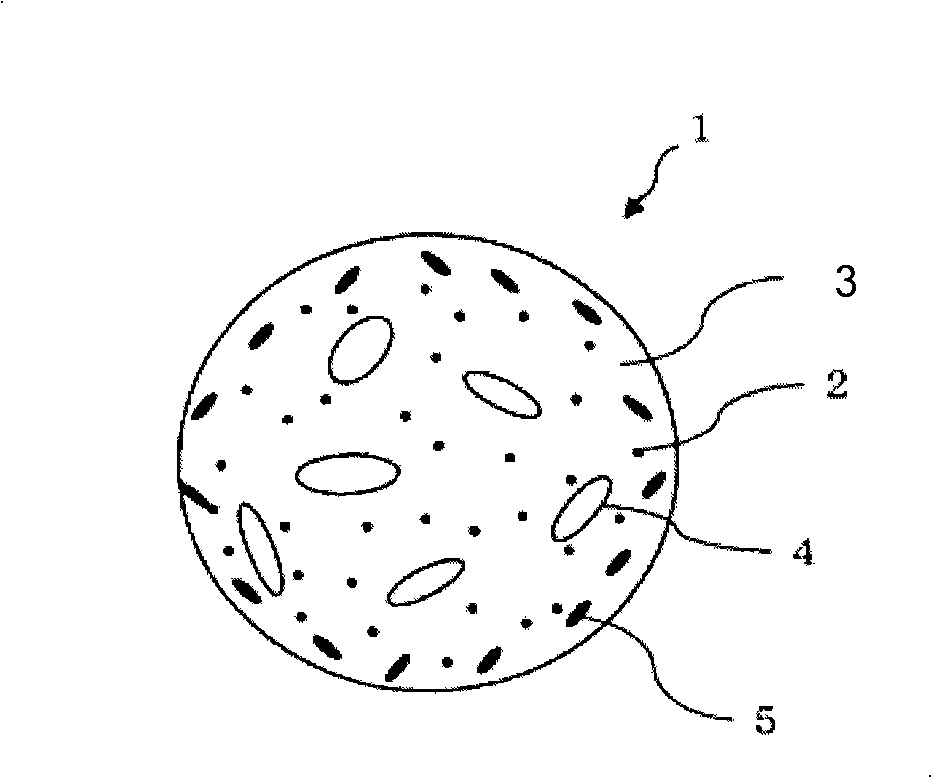

Latent electrostatic image developing toner, image forming apparatus and image forming method

An electrostatic latent image and toner technology, which is applied in the field of electrostatic latent image development toner, can solve problems such as degradation, toner film-forming and fixing performance, and achieve good durability, less space, low-temperature fixing performance and heat resistance and storage performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0173] (preparation of masterbatch)

[0174] [0136] A masterbatch can be prepared by mixing and kneading a resin and a colorant while applying high shear force thereto. Organic solvents can be used to enhance the interaction between the colorant and the resin. Furthermore, a flushing method is preferably used. In the flushing method, an aqueous paste containing water and a colorant is mixed and kneaded with a resin and an organic solvent, so that the colorant moves to the resin, and the water and the organic solvent are removed. Therefore, it is not necessary to dry the colorant wet cake. Therefore, a flushing method is preferably used. For mixing and kneading, a high shear dispersing mixer such as a three-roll mill is preferably used.

[0175]

[0176] [0137] Any known antiblocking agent may be used in the toners described herein. Examples of the release agent include polyolefin waxes such as polyethylene wax and polypropylene wax; hydrocarbons having long chains such ...

Embodiment 1

[0317]

[0318] [0223] The following ingredients were charged into a container equipped with a thermometer and a stirrer: 96 parts of polyester (1); 32 parts of paraffin wax (melting point 72° C.); montmorillonite (CLAYTONAPA, manufactured by Southern Clay Inc., an inorganic layered mineral in which some of the interlayer ions are modified by a quaternary ammonium salt having a benzyl group) 8 parts; and ethyl acetate 383 parts. The mixture was stirred, heated to 80°C and held at 80°C for 5 hours. The mixture was cooled to 30°C within 1 hour. The mixture was transferred to different containers, and under the conditions of "3 pass" liquid transfer rate of 1 kg / hr, disc peripheral speed of 6 m / sec and 80% by volume loading of 0.5 mm zirconia beads, Bead mill (ULTRA VISCO MILL, manufactured by Aimex Co., Ltd.) dispersion. Component solution (1) is thus obtained. To 325 parts of ingredient solution (1) was added 338 parts of a 70% solution of polyester (1) in ethyl acetate an...

Embodiment 2

[0335] [0235] The electrostatic latent image developing toner (developer (2)) of the present invention is obtained in the same manner as in Example 1, except that P-1 is replaced with the first binder resin P-2 and the first resin The ratio of P-2 and the second resin PP-1 was varied. Table 1 shows the ratio (% by mass) of the first resin and the second resin in the obtained developer (2), the acid value of the first resin, the volume average particle diameter (Dv) and number of the toner. Average particle size (Dn), its ratio (Dv / Dn) and average circularity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com