Electric automatization control device used for heavy hydraulic press

A technology of electrical automation and control devices, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of lack of man-machine dialogue, low degree of automation, and poor adaptability, etc. Communication, high degree of automation, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation.

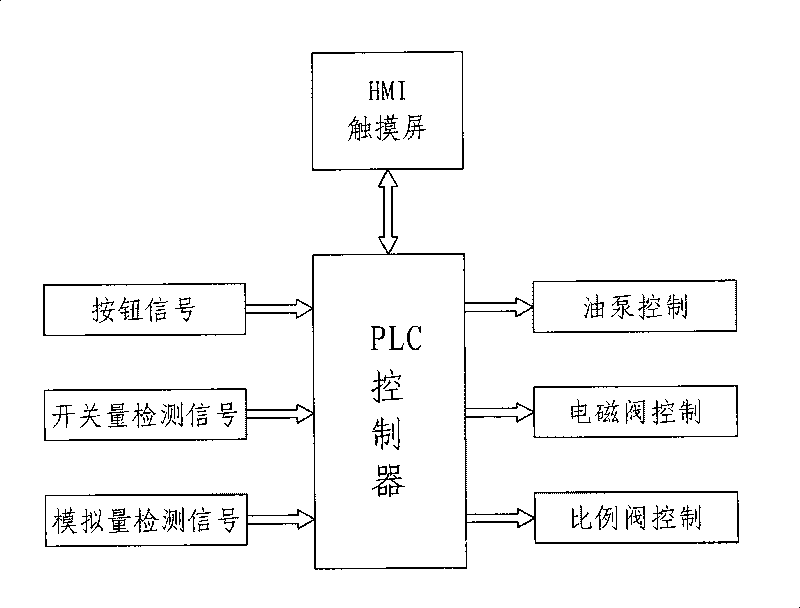

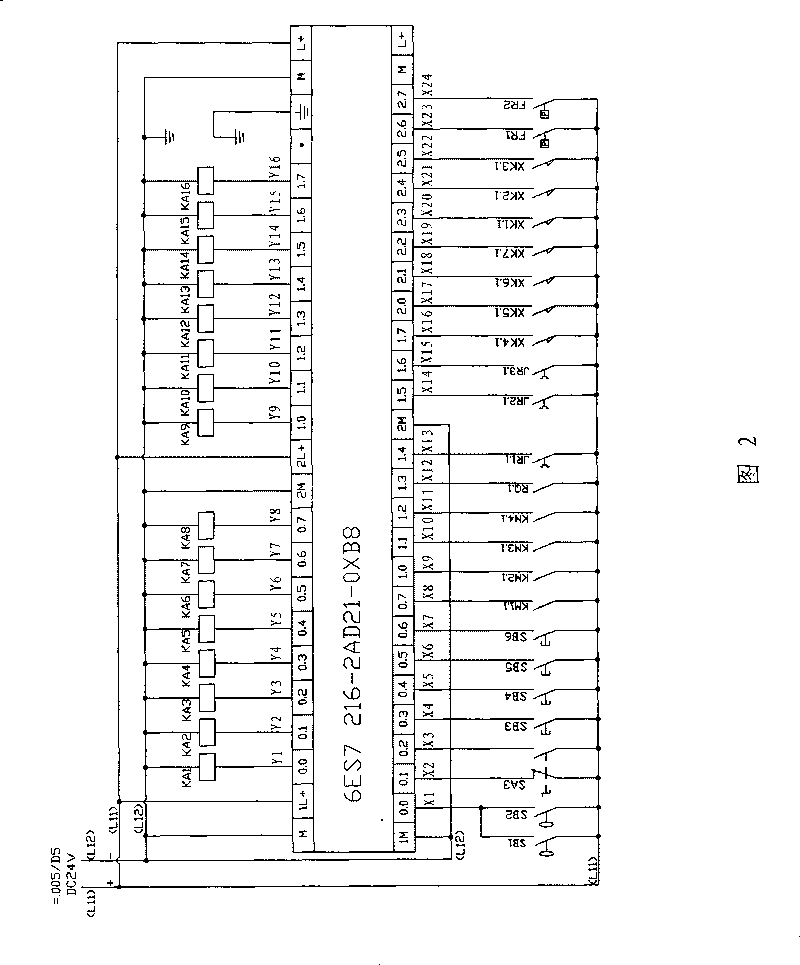

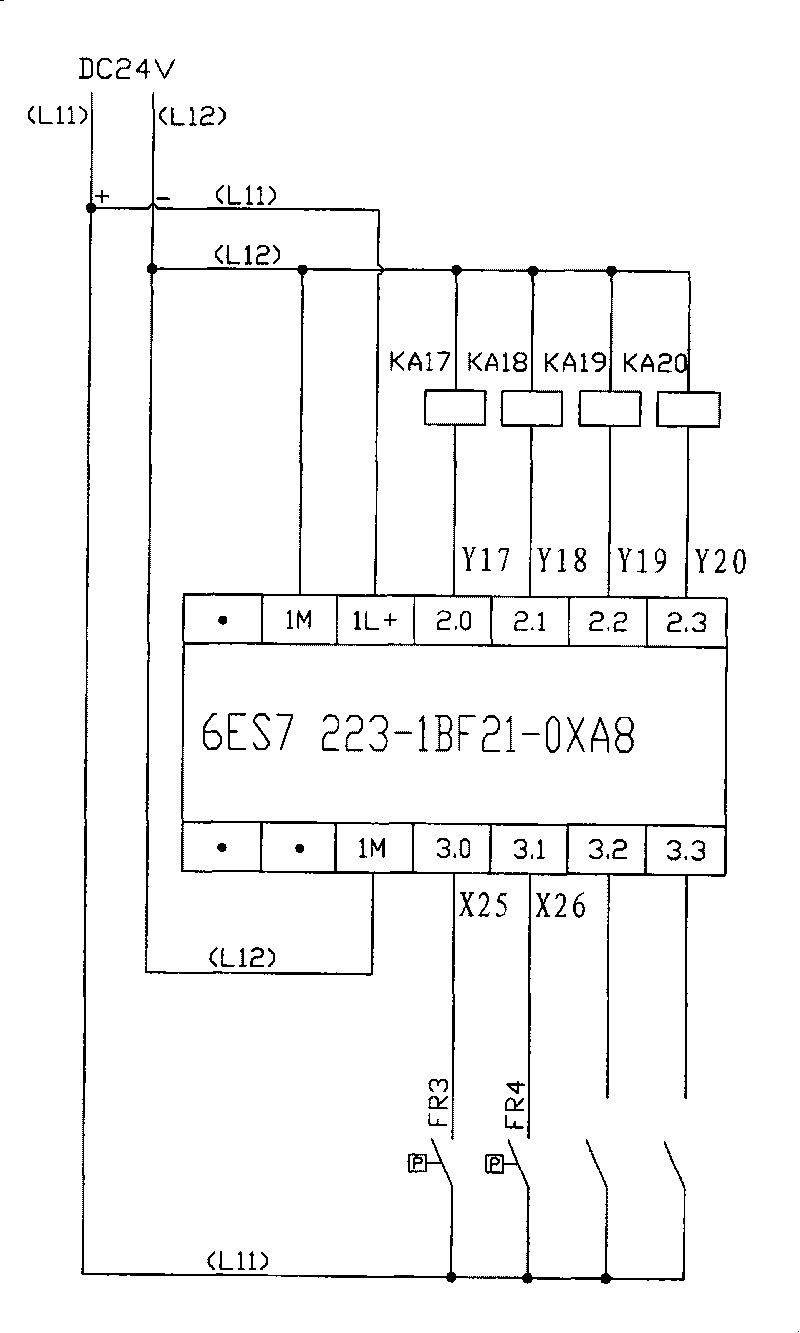

[0026] like figure 1 As shown, the electrical automation control device applied to heavy hydraulic presses in this embodiment is composed of four parts: input, control operation, output and display touch screen, wherein:

[0027] ①The input part consists of three parts: operation button, switch signal detection and analog signal detection. The operation button is manually operated by humans to deal with emergency situations. Signal detection means that the sensor of the system automatically monitors the working conditions of the heavy-duty hydraulic press. Once an abnormal situation occurs, an alarm will be issued to remind the operator immediately, and corresponding fault pretreatments will be carried out, such as emergency shutdown processing, so as to avoid accidents.

[0028] ②The control calculation part takes the PLC controller as the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com