Protection type brushless excitation synchronous motor

A synchronous motor and exciter technology, which is applied to synchronous motors, asynchronous induction motors, electric components, etc. for single-phase current, can solve problems such as expansion of installation base, increase in investment cost, and long motor shaft, and achieve high protection level. , improve safety, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

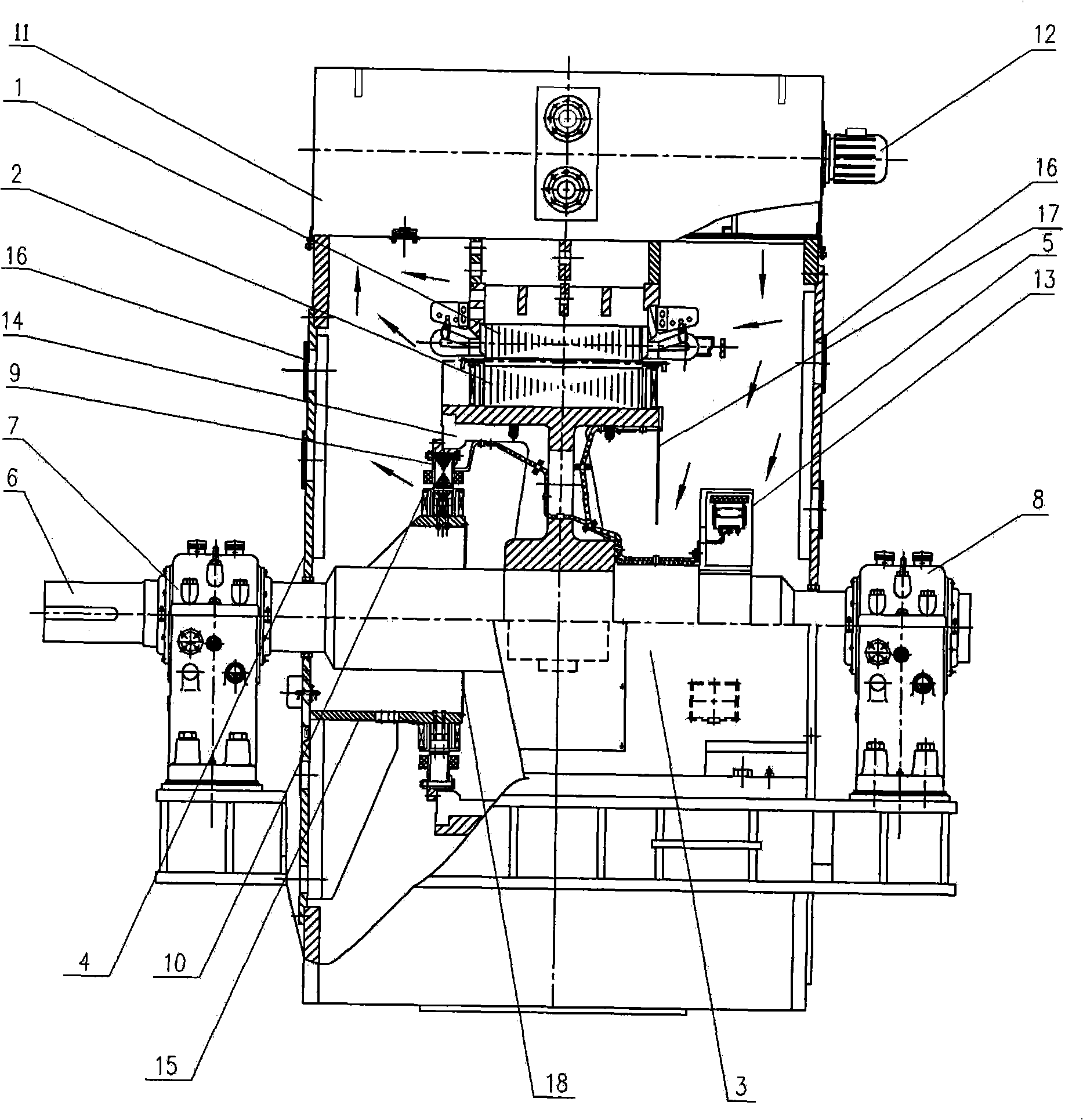

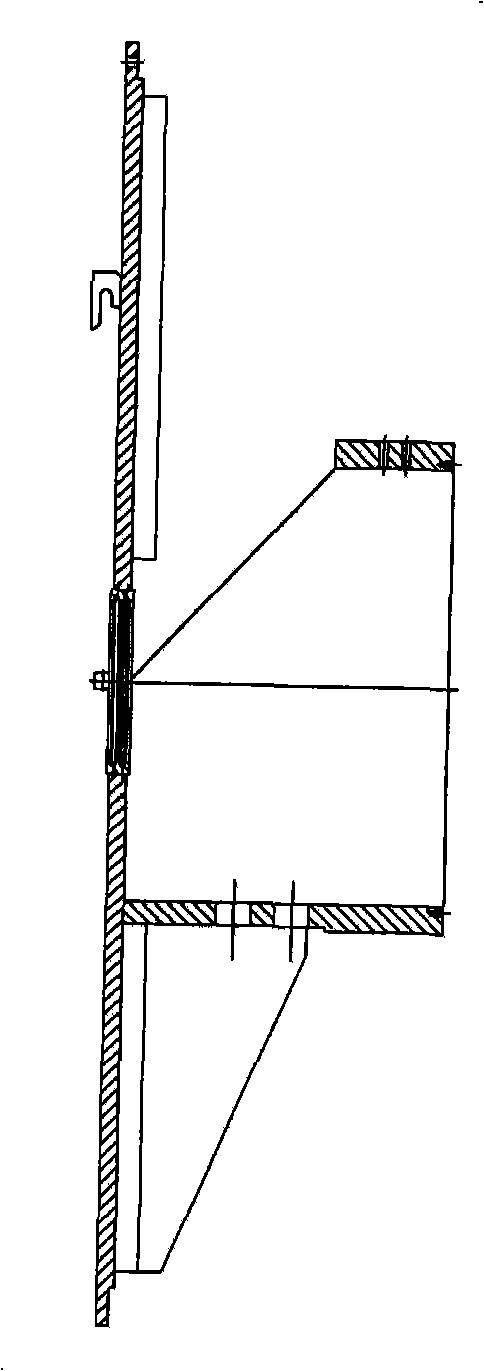

[0015] refer to figure 1 , this embodiment includes the motor host stator 1, the rotor 2, the base 3, the end cover 4 and the end cover 5 at both ends of the base, the shaft 6 and the non-insulated seat bearing 7 and the insulating seat bearing 8 at both ends of the shaft, the exciter The stator 9 and the magnetic pole 10, the cooler 11 located on the upper part of the machine base, the blower 12 installed on the non-load end, the rectifier disc 13, the left end, that is, the end cover 4 at the load end, is located on the side of the machine base with an inner diameter larger than the shaft radius and an outer diameter. The beveled cylinder 15 which is smaller than the inner diameter of the flange of the rotor yoke 14 of the main engine, the exciter pole 10 is installed on the outer circumference of the end of the beveled cylinder 15 of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com