Electric field warming and processing device and method

A processing device and electric field technology, applied in the direction of dielectric heating, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems of high electric attenuation rate, electrodes that cannot be easily washed and cleaned, irregularities, etc., to achieve heat exchange reduction, Solve the effect of a large amount of processing in a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

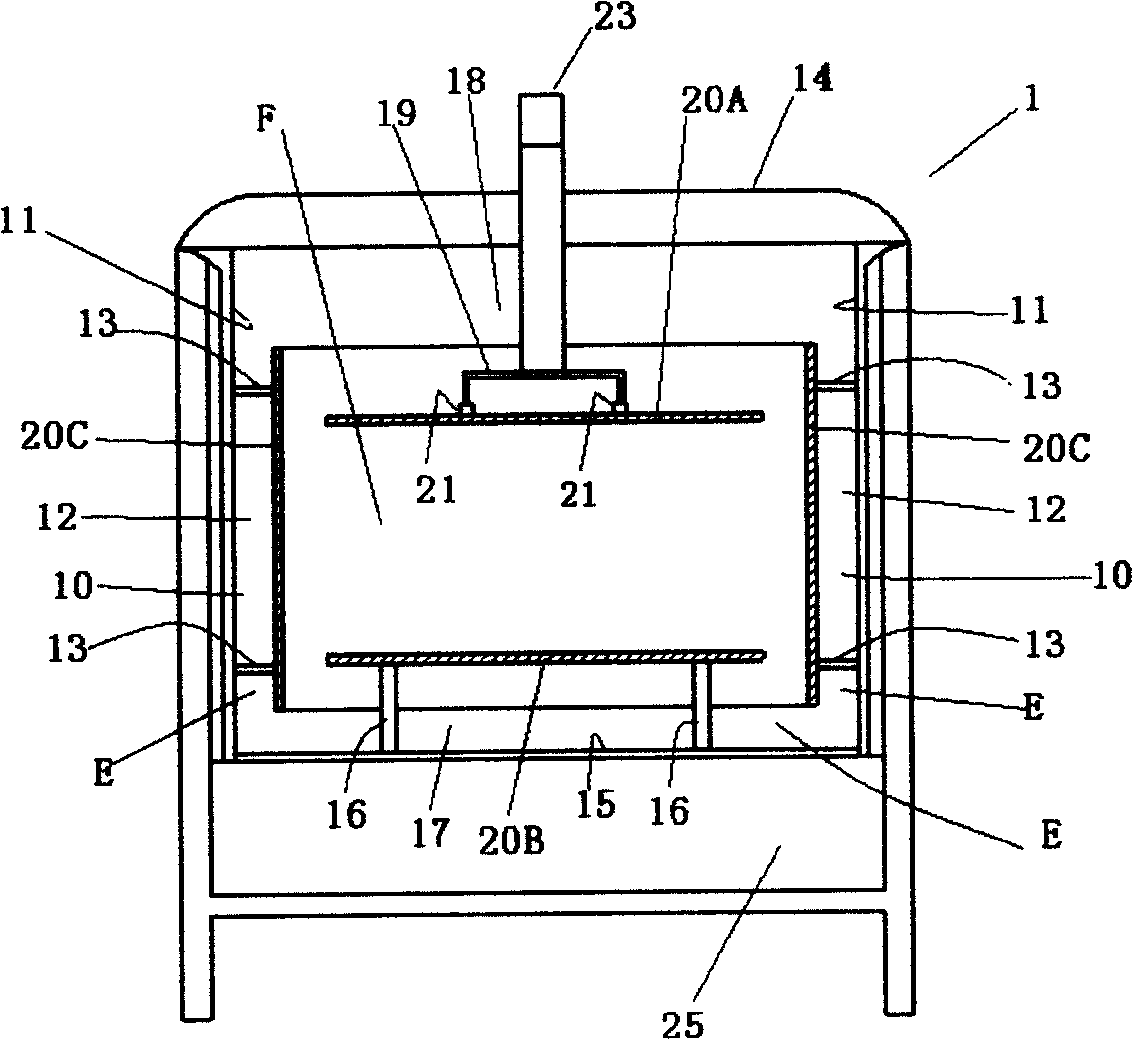

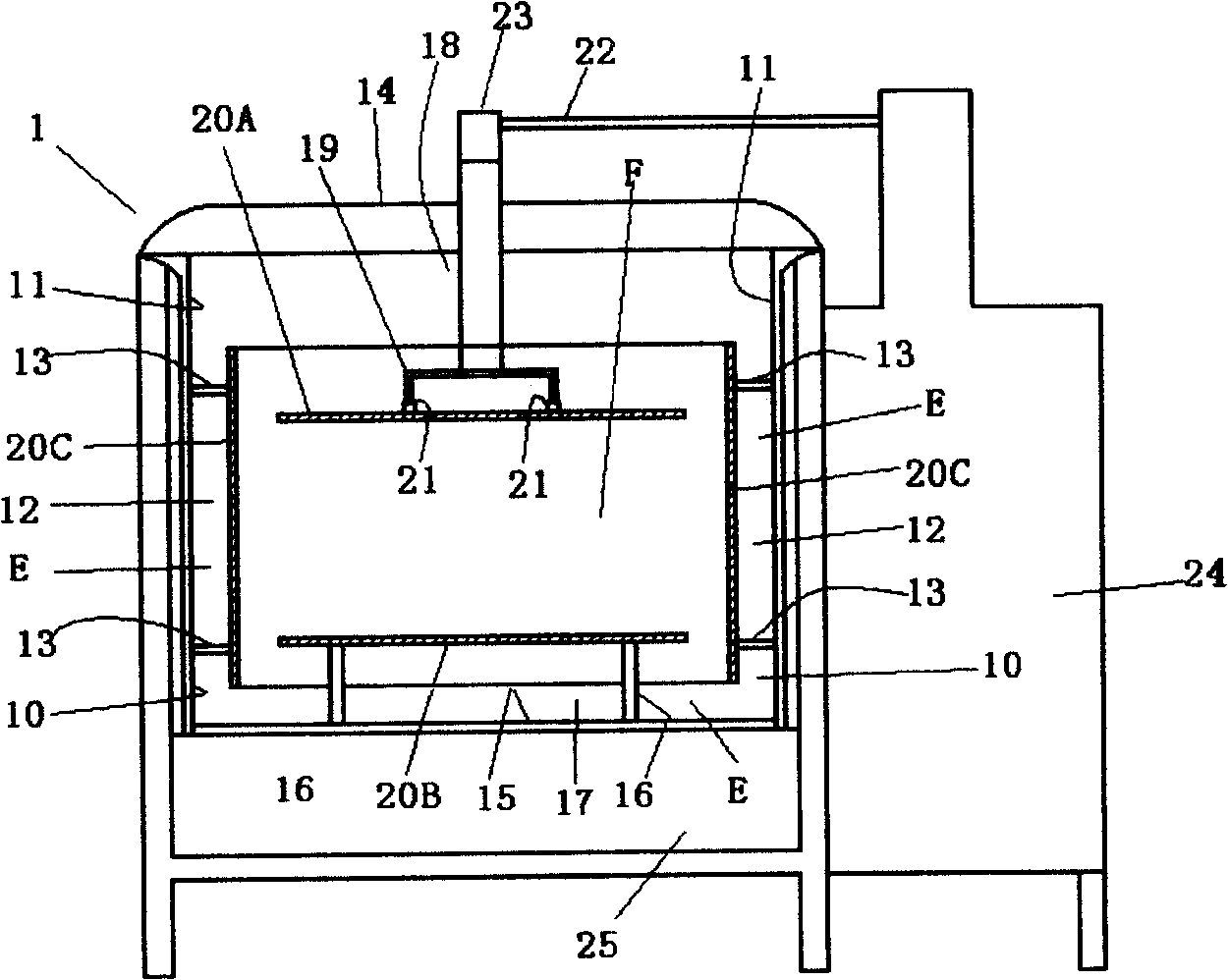

[0064] figure 1 , figure 2 Shown are a schematic front sectional view and a schematic side sectional view of a batch-type electric field treatment heating processing apparatus according to a first embodiment of the present invention.

[0065] The classification of the electric field treatment area of the batch type electric field treatment heating processing device in this embodiment 1 is a device for fluids (such as oil, etc.) with a small dielectric constant.

[0066] Batch-type electric field treatment heating processing device 1 is composed of a heat medium fluid containing part, a fluid electrode structure part, a material electrode structure part, an external part of the electric field treatment heating processing device, a heating system device, and a power supply device for forming an electric field. , The electrode drive device for the substance, and the mechanical housing part of the open and close drive device for the cover of the electric field treatment area....

Embodiment 2

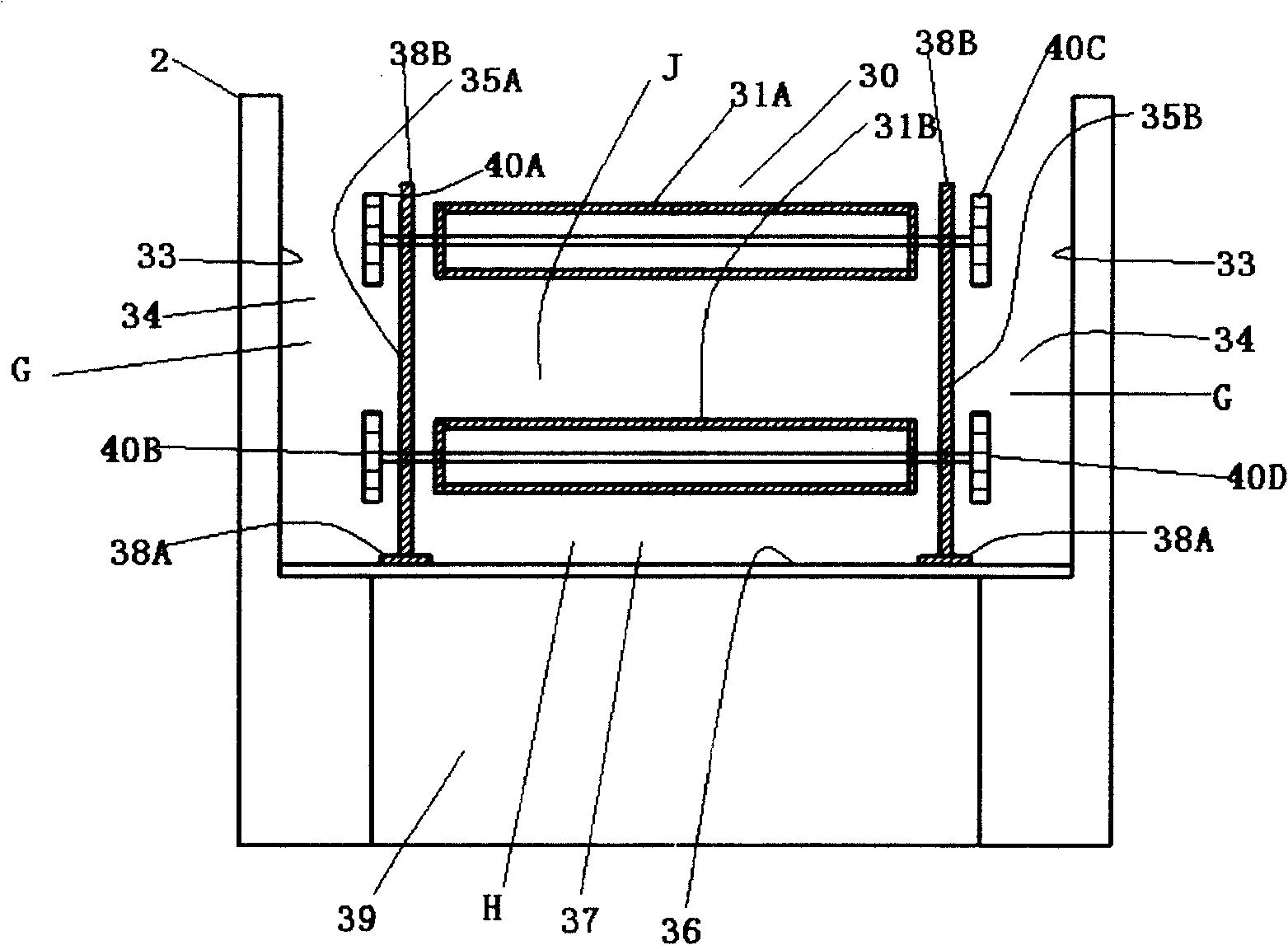

[0080] image 3 , Figure 4 Shown are a schematic front sectional view and a schematic side sectional view of a conveyor-type electric field treatment heating processing apparatus according to a second embodiment of the present invention.

[0081] The present embodiment 2 relates to a conveyor-belt electric field treatment heating processing device for a fluid with a small fluid dielectric constant (such as oil, etc.) as a heat medium.

[0082] The conveyor belt type electric field treatment heating processing device 2 is composed of a fluid containing part, a material electrode structure part, a fluid electrode structure part, a power supply device for electric field formation, a driving device for driving the material electrode, and a material electrode for driving and adjusting the distance between the material electrodes. It consists of a driving device for adjusting the functional part and a mechanical housing part for housing the heating device. The power supply device...

Embodiment 3

[0092] Figure 5 , Figure 6 Shown are a schematic front sectional view and a schematic side sectional view of a batch-type electric field treatment heating processing apparatus according to Example 3 of the present invention.

[0093] The present embodiment 3 relates to a batch-type electric field treatment heating processing device for a fluid with a large dielectric constant (such as water, etc.) as a heat medium.

[0094] The batch-type electric field treatment heating processing device 3 is composed of a heat medium fluid storage part, a fluid electrode structure part, a material electrode structure part, the peripheral part of the heating processing device, a storage heating system device, a power supply device for electric field formation, and a material electrode. The driving device and the mechanical housing part of the opening and closing driving device of the cover of the electric field treatment area are constituted.

[0095] The fluid electrode and the substance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com