Electromagnetic centrifugal casting quick-cutting steel composite roller operational layer material

A technology of centrifugal casting and composite rolls, applied in the field of metallurgical rolls, can solve the problems of poor wear resistance, affecting service performance, microstructure segregation, etc., and achieve the effects of avoiding macrosegregation, improving overall performance, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

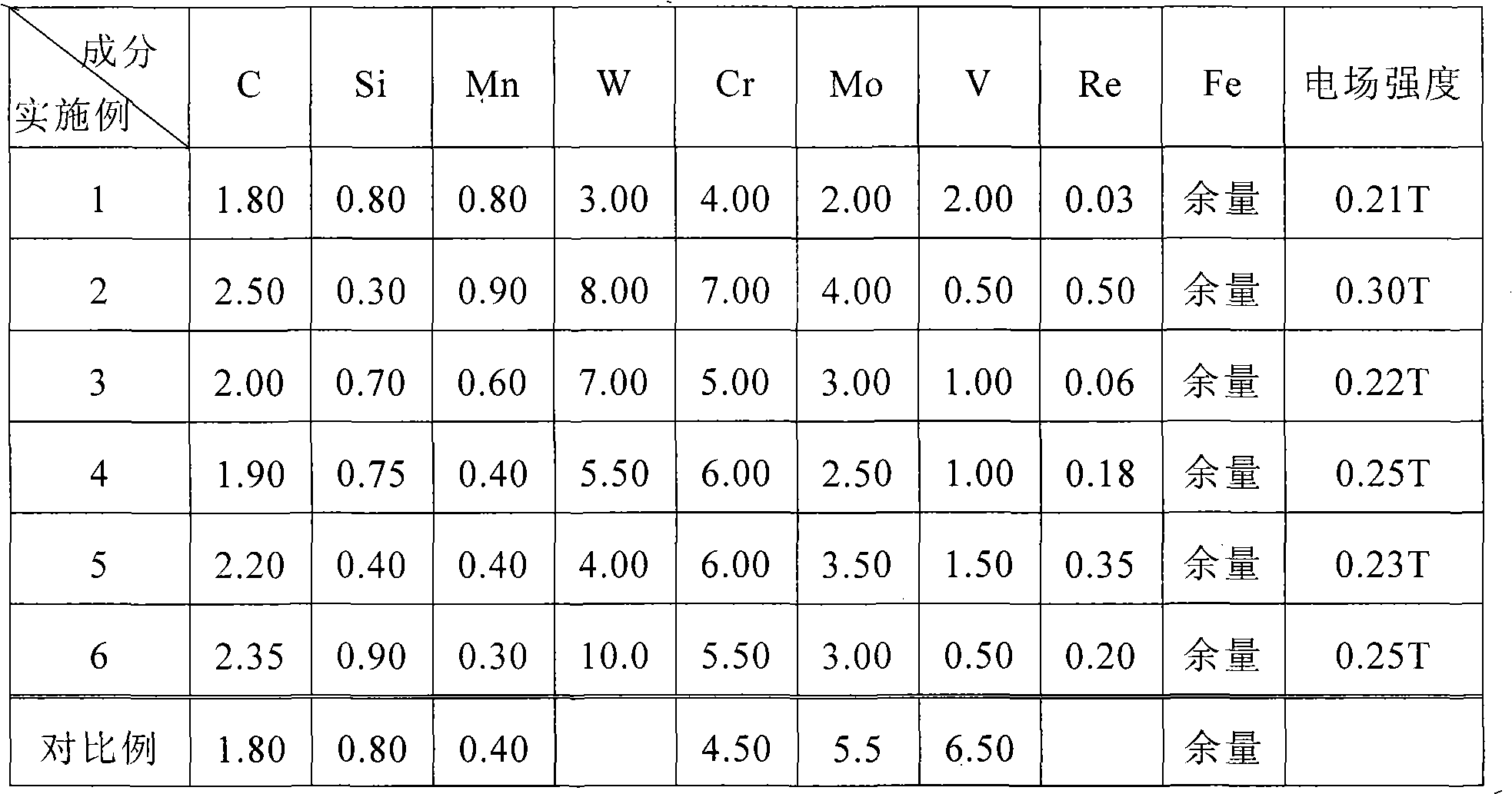

[0039] See Table 1 for examples of the present invention.

[0040] Table 1 Unit: mass percentage

[0041]

[0042] In the process of centrifugal casting and solidification of the working layer of the roller body, an electromagnetic field with a magnetic induction intensity of 0.21T-0.30T is applied, and W is used instead of V. The carbides can be evenly distributed without segregation, and the structure is dense and fine. The performance is better than ordinary centrifugal. Cast high-speed steel rolls, among which: the wear resistance and impact toughness are increased by more than 30%, and the anti-accident performance is greatly improved.

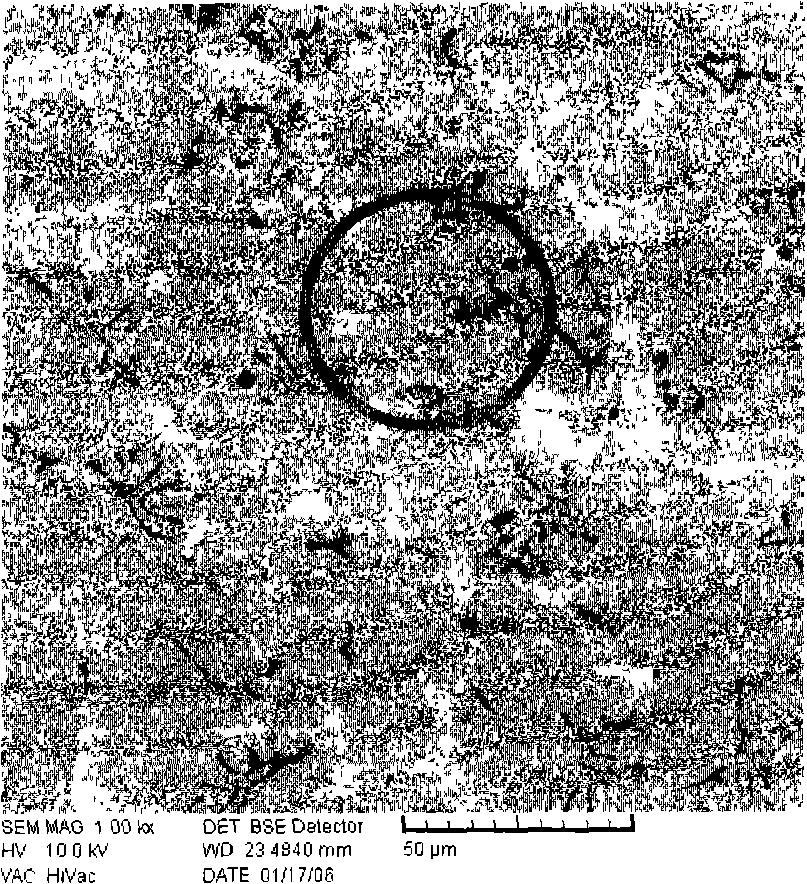

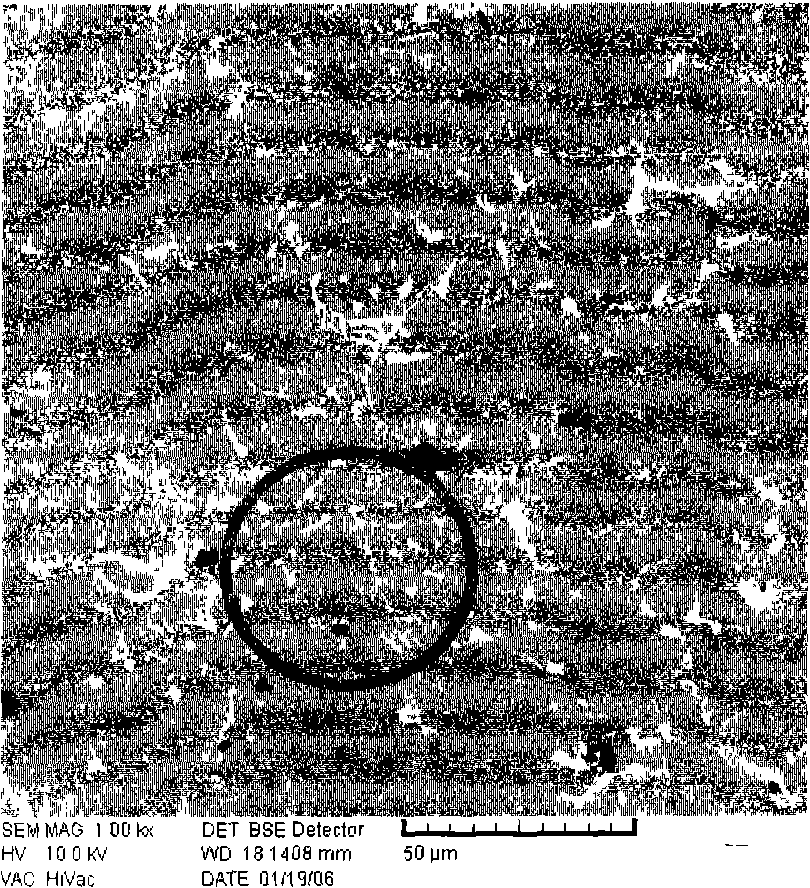

[0043] Depend on figure 1 , figure 2 It can be seen that the heat treatment process remains unchanged, and under the condition of no electromagnetic field centrifugal casting, a large amount of black carbides are precipitated and aggregated; under the condition of 0.22T electromagnetic field centrifugal casting, a large amount of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com