A kind of rare earth steel and its preparation method

A rare earth and steel plate technology, applied in the field of iron and steel metallurgy, can solve the problems of difficulty in producing ODS-RAFM steel, easy oxidation and pollution of powder, poor product reproducibility, etc., to improve high temperature oxidation resistance, avoid macrosegregation, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

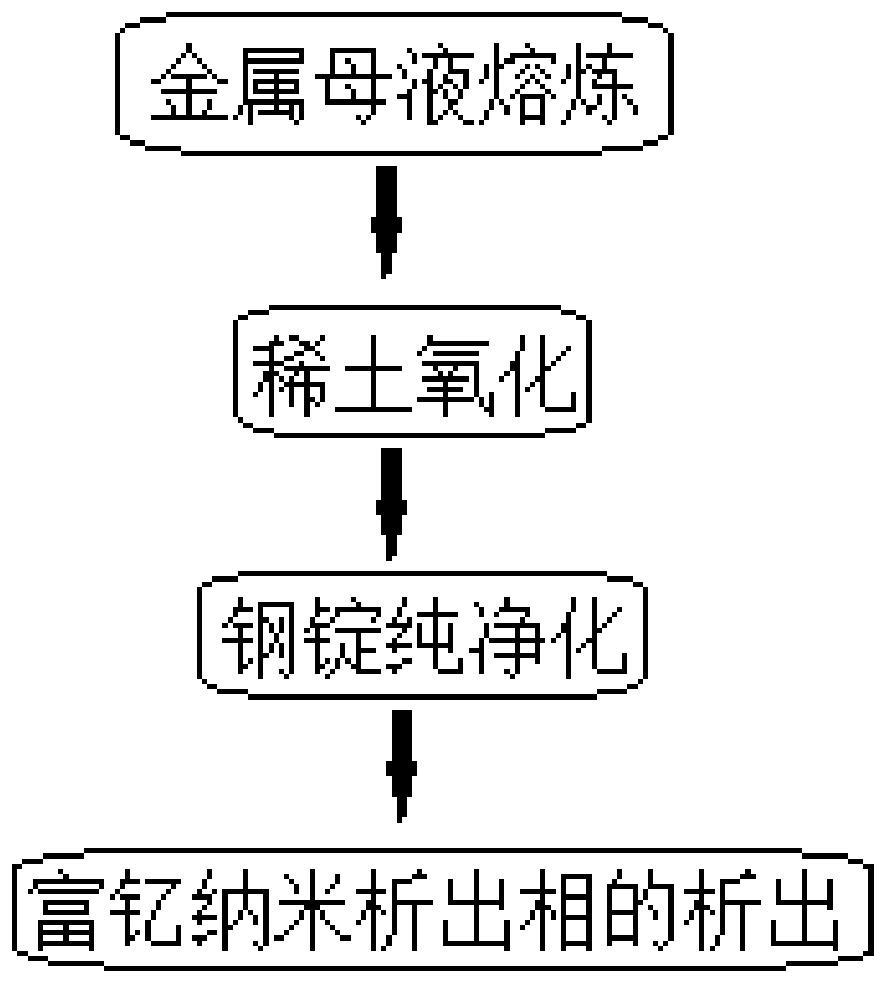

[0035] The preparation method of rare earth steel of the present invention comprises the steps:

[0036] (1) Metal mother liquor smelting

[0037] Put metal chromium, tungsten, tantalum and iron in the zirconia crucible in the vacuum induction furnace, turn on the vacuum pump, evacuate to 5-10Pa, and melt the alloy in the furnace under vacuum; after the alloy is melted, lower the temperature of the alloy liquid Adjust to 1650-1700°C, add deoxidizer (high-purity graphite carbon, its carbon content ≥ 99.99%) for deoxidation; after the oxygen mass fraction in the alloy liquid is removed below 10ppm, adjust the temperature of the alloy liquid to 1550-1600°C , add alloy silicon and alloy manganese; after alloy silicon and alloy manganese are melted, add rare earth yttrium; add rare earth yttrium and refine for 30 to 40 minutes, and carry out sufficient electromagnetic stirring to promote the comprehensive dissolution and homogenization of rare earth yttrium.

[0038] (2) rare eart...

Embodiment 1

[0047] This embodiment takes the smelting of 100kg rare earth steel as an example. The chemical components and their mass percentages of rare earth steel are: C: 0.01%, Si: 0.2%, Mn: 0.5%, Cr: 8%, W: 2% , V: 0.23%, Ta: 0.1%, Zr: 0.001%, Y 2 o 3 : 0.3%, the rest is Fe.

[0048] The preparation method of the present embodiment rare earth steel comprises the steps:

[0049] (1) Metal mother liquor smelting

[0050] Put metal chromium, tungsten, tantalum and iron in the zirconia crucible in the vacuum induction furnace, turn on the vacuum pump, evacuate to 5-10Pa, and melt the alloy in the furnace under vacuum; after the alloy is melted, lower the temperature of the alloy liquid Adjust to 1650°C, add a deoxidizer (high-purity graphite carbon, its carbon content ≥ 99.99%) for deoxidation; after the oxygen mass fraction in the alloy liquid is removed below 10ppm, adjust the temperature of the alloy liquid to 1550°C, and add alloy silicon and alloy manganese; after the alloy sili...

Embodiment 2

[0060] This embodiment takes the smelting of 100kg rare earth steel as an example. The chemical components and their mass percentages of rare earth steel are: C: 0.05%, Si: 0.15%, Mn: 0.45%, Cr: 9%, W: 2.3% , V: 0.25%, Ta: 0.08%, Zr: 0.05%, Y 2 o 3 : 0.3%, the rest is Fe.

[0061] The preparation method of the present embodiment rare earth steel comprises the steps:

[0062] (1) Metal mother liquor smelting

[0063] Put metal chromium, tungsten, tantalum and iron in the zirconia crucible in the vacuum induction furnace, turn on the vacuum pump, evacuate to 5-10Pa, and melt the alloy in the furnace under vacuum; after the alloy is melted, lower the temperature of the alloy liquid Adjust to 1670°C, add deoxidizer (high-purity graphite carbon, its carbon content ≥ 99.99%) for deoxidation; after the oxygen mass fraction in the alloy liquid is removed below 10ppm, adjust the temperature of the alloy liquid to 1570°C, add alloy silicon and alloy manganese; after the alloy silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com