Printing substrate processing machine

A processing machine and printing-based technology, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of complex worktable rigidity and other problems, and achieve the effects of simple structure, deformation prevention, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

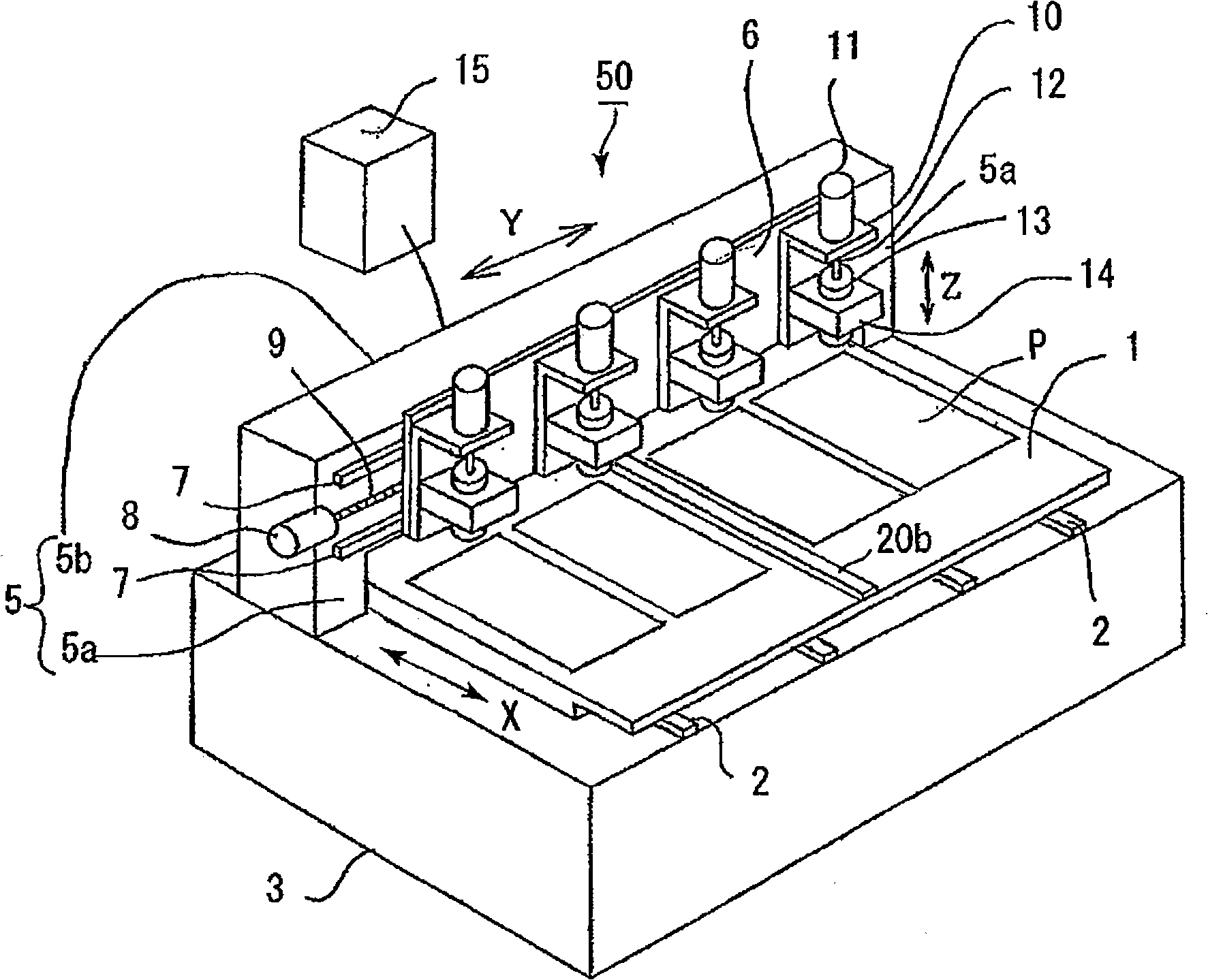

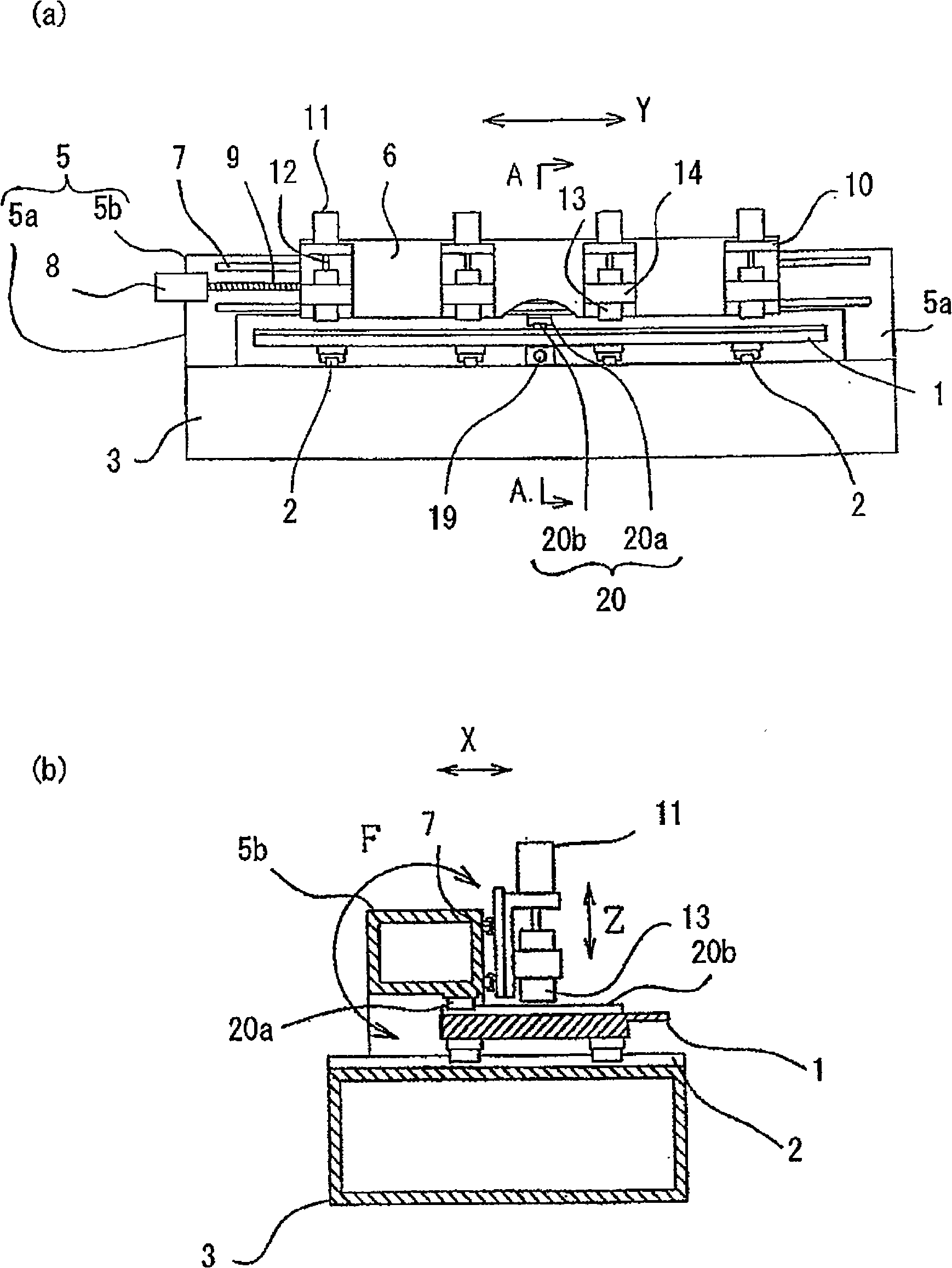

[0027] Hereinafter, a printed substrate processing machine according to an embodiment of the present invention will be described with reference to the drawings.

[0028] figure 1 It is an external perspective view of the printed circuit board processing machine in the embodiment of the present invention. figure 2 (a) is figure 1 Front view of the printed substrate processing machine. figure 2 (b) is figure 2 (a) A-A arrow sectional view.

[0029] The printed substrate processing machine 50 drills holes in the printed substrate P. As shown in FIG. The table 1 is supported on the linear guide device 2, and is passed through a drive motor and a feed screw 19 (not shown). figure 2 ) on the base 3 along the arrow X direction. Four (not limited to four) printing substrates P are fixed on the table (X table) 1 .

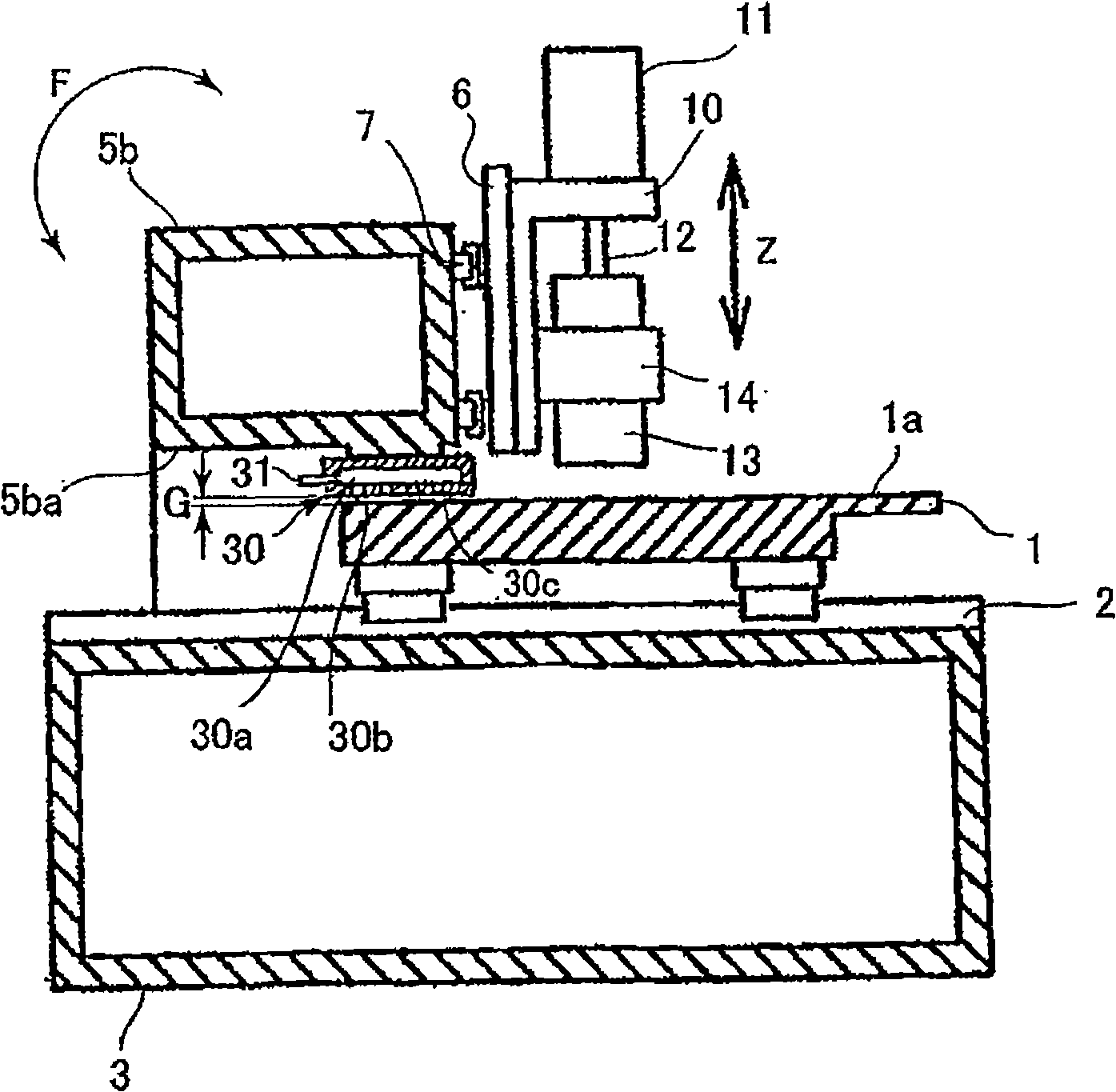

[0030] The pillar 5 is constituted by a pair of leg parts 5a and a beam part 5b connecting the pair of leg parts 5a, is formed in a gate shape, straddles the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com