Method for manufacturing non-volatile microelectromechanical memory unit

A memory unit, non-volatile technology, applied in the direction of static memory, digital memory information, manufacturing microstructure devices, etc., can solve problems such as difficult design and manufacture of embedded non-volatile memory devices, to achieve accurate switching voltage, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

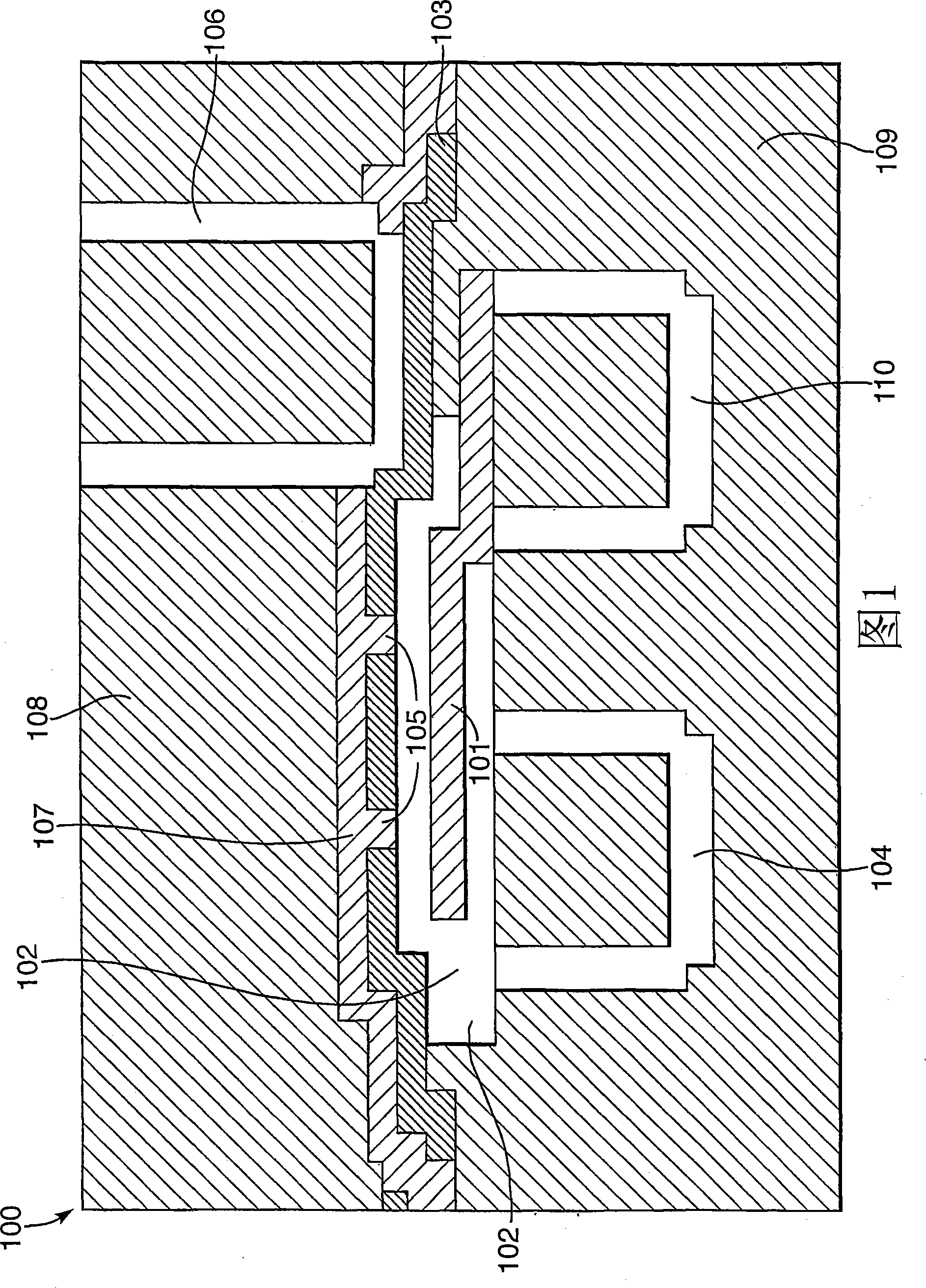

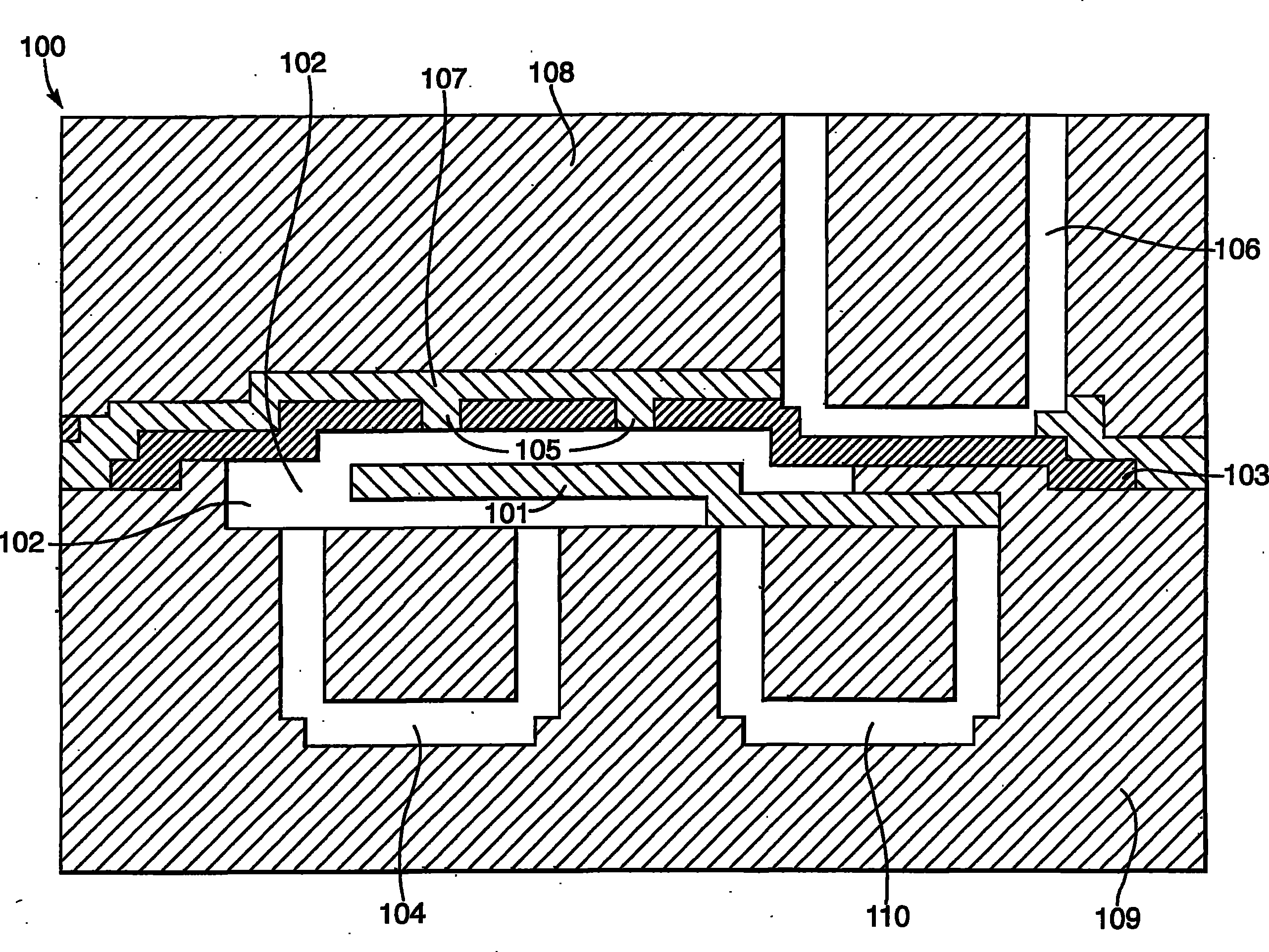

[0033] see figure 1 , the first example of the present invention will now be described. In the first example, device 100 is a scaled-down version of a microelectromechanical cantilever device, fabricated in part by atomic layer deposition (ALD). The first dielectric material layer 109 includes a pull-down electrode 104 and a cantilever electrode 110 .

[0034] On this dielectric material layer 109, a cantilever 101 surrounded by a sacrificial material (not shown) is formed by alternately depositing a sacrificial material and a cantilever material. A conductive material layer 103 is then deposited over the second sacrificial material layer. Two release holes 105 are then etched in the conductive layer 103 . Next, sacrificial material is etched through the release hole 105 . When the sacrificial material is etched away, a cavity 102 is formed in which the cantilever 101 is suspended.

[0035] An insulating layer 107 is then deposited over the conductive layer 103, which act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com