Band press filter with mud fixing belt

A technology of belt filter press and press filtration, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc. It can solve the problems of backward, unable to solve the problem of dehydration of materials at the feed inlet, and limited implementation, and achieve a reasonable structure , to ensure normal and continuous operation, and to ensure the effect of pressing dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below through the embodiments in conjunction with the accompanying drawings.

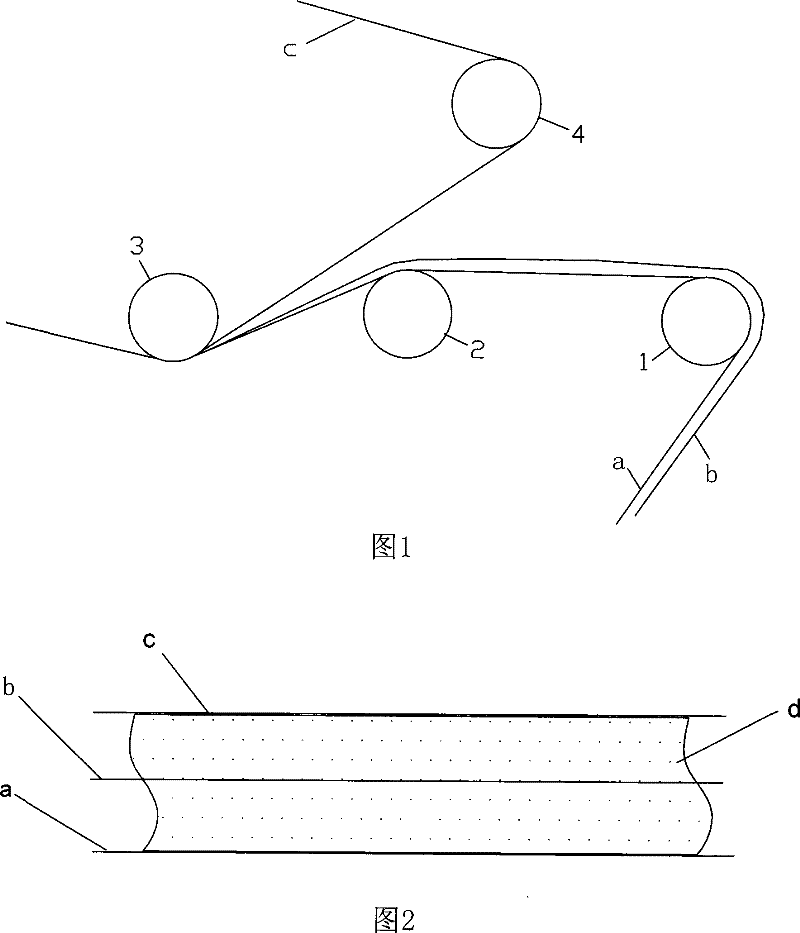

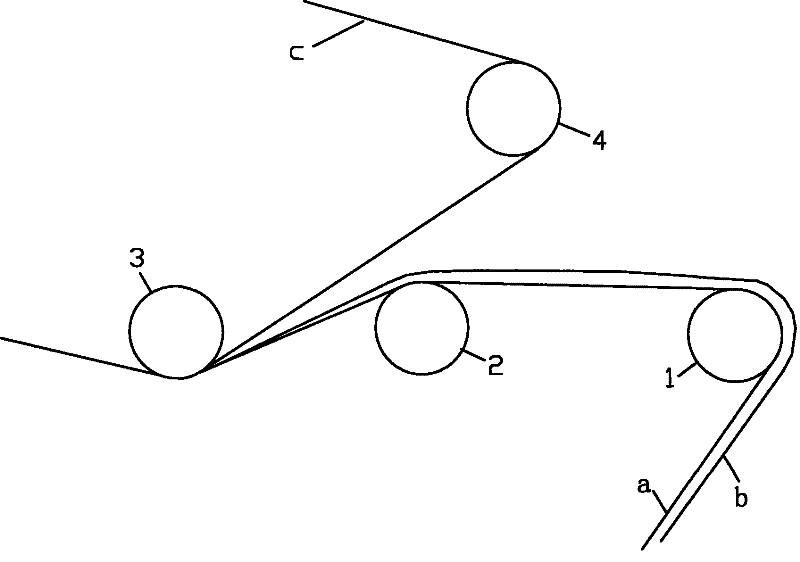

[0014] Referring to Fig. 1 , the belt filter press with a solid mud belt is mainly composed of a frame, a driving device, a feeding device, a press filter area and auxiliary devices. Press filter area includes 1 # Press roll 1, 2 # Press roll 2, 3 # Press roll 3, 4 # Squeeze roll 4 etc., lower filter belt a, solid mud belt b and upper filter belt c, upper filter belt c is wrapped in 4 # Press rolls 4 and 3 # Outside the squeeze roller 3, etc., the solid mud belt b is stacked on the lower filter belt a, and is wrapped together with the lower filter belt a in 1 # Press rolls 1 and 2 # Press roll 2 and so on. The press filter area is installed on the frame, the driving device and the press filter area 1 # Press roll 1, 2 # Press roll 2, 3 # Press roll 3, 4 # Squeeze rollers 4 etc. are connected, the feed device is facing the feed inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com