Filtration equipment with swirling backwashing function, filtering method thereof, and backwashing method

A technology of filtering equipment and functions, which is applied in the field of filtering equipment with swirling backwashing function, can solve the problems of filter material running out and incomplete cleaning of filter material, achieve guaranteed effect, avoid material running out, and save operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

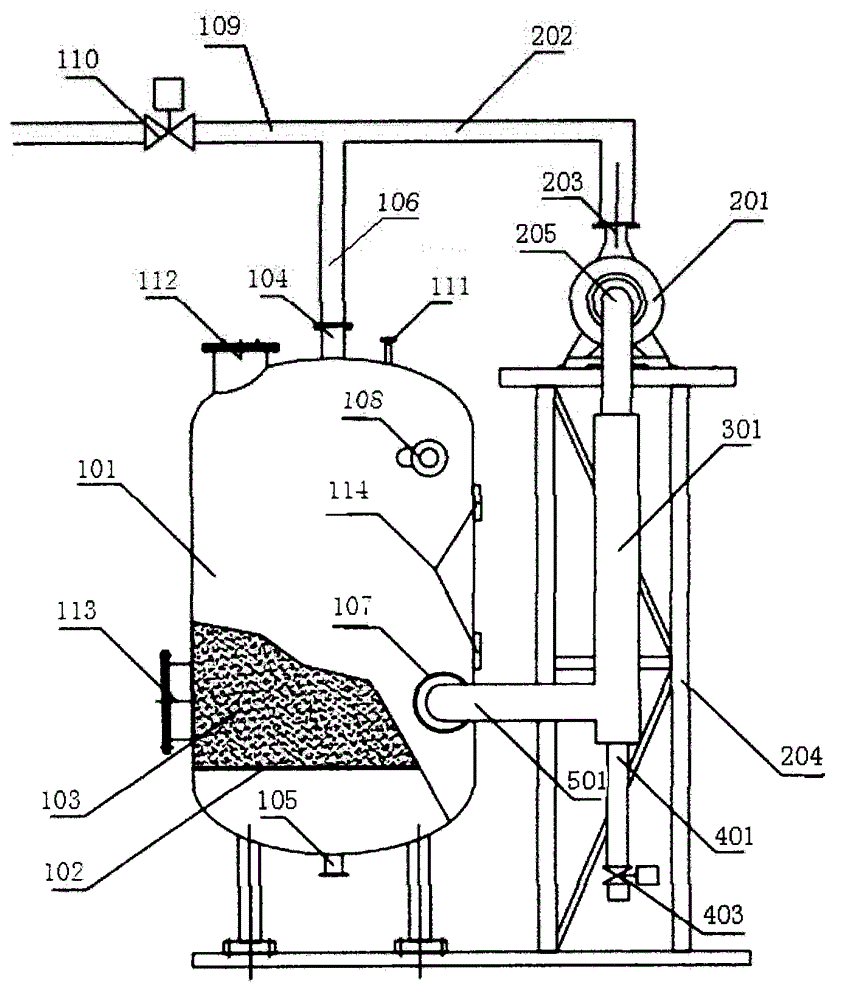

[0021] Embodiment 1, this embodiment proposes a filter device with cyclone backwashing function, such as figure 1 As shown, the filter tank 101 is included, the filter tank 101 is provided with a sieve plate 102 and a walnut shell filter material 103 arranged on the upper layer of the sieve plate 102, the filter tank 101 includes a top opening 104 and a bottom opening 105, the A connecting pipe 106 is provided at the top opening 104, and the top opening 104 is connected to the water inlet pipe 109 through the connecting pipe 106, and also includes a cleaning pump 201 and a screen pipe 301, and the connecting pipe 106 is also fed into the water through the cleaning pump The water pipe 202 is connected to the pumping port 203 of the cleaning pump 201, the connecting pipe 106 is provided with a first valve 110, one end of the screen pipe 301 is connected to the discharge port 205 of the cleaning pump, and one of the other ends is It is connected with the blowdown pipe 401, and th...

Embodiment 2

[0030] Embodiment 2, based on the filtering device in Embodiment 1, this implementation proposes a filtering method and a backwashing method for the aforementioned filtering device. The structural features of the filtering device can be referred to in Embodiment 1, and will not be described here. To repeat, the filtering method and the backwashing method of the present embodiment include the following steps:

[0031] During the filtration process, the first valve is turned on, and the oily sewage enters the filter tank through the connecting pipe and the top opening successively from the water inlet pipe. The walnut shell filter material absorbs and intercepts the solid particles and crude oil particles in the dispersed phase, and the water molecules in the continuous phase After passing through the walnut shell filter material and sieve plate, it is discharged from the bottom opening;

[0032]In the backwashing process, the first valve is closed, the cleaning pump is working,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com