Anti-blocking structure of sodium hypophosphite reaction kettle buffer tank

A sodium hypophosphite and buffer tank technology, applied in the field of chemical production, can solve problems such as increased safety hazards, material running, and lime scaling accumulation, and achieve the effects of ensuring safety, preventing material running, and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below according to the accompanying drawings.

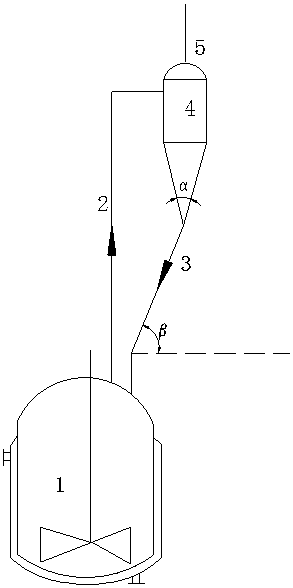

[0012] Such as figure 1 The anti-clogging structure of the buffer tank of the sodium hypophosphite reactor shown in the structure includes a reactor 1, an outlet pipe 2, a return pipe 3, a buffer tank 4, and an outlet pipe 5 of the buffer tank; wherein the buffer tank 4 is located above the reactor 1 , the bottom of the buffer tank 4 is connected to the top return inlet of the reactor 1 through a return pipe, the gas outlet at the top of the reactor 1 is connected to the side top of the buffer tank 4 through the gas outlet pipe 2, and the buffer tank gas outlet pipe 5 is arranged on the top of the buffer tank 4 surface.

[0013] The bottom of the buffer tank 4 is a cone bottom, and the optimum cone angle α is 25 to 35°;

[0014] The air outlet pipe 2 enters in the upper part of the cylinder of the buffer tank 4 along the tangential direction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com