Device for circularly grinding and dispersing and method thereof

A cyclic grinding and dispersing device technology, applied in mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of small particle size and particle size distribution, large energy consumption, low dispersion quality and dispersion efficiency that cannot meet the requirements of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. Device embodiment

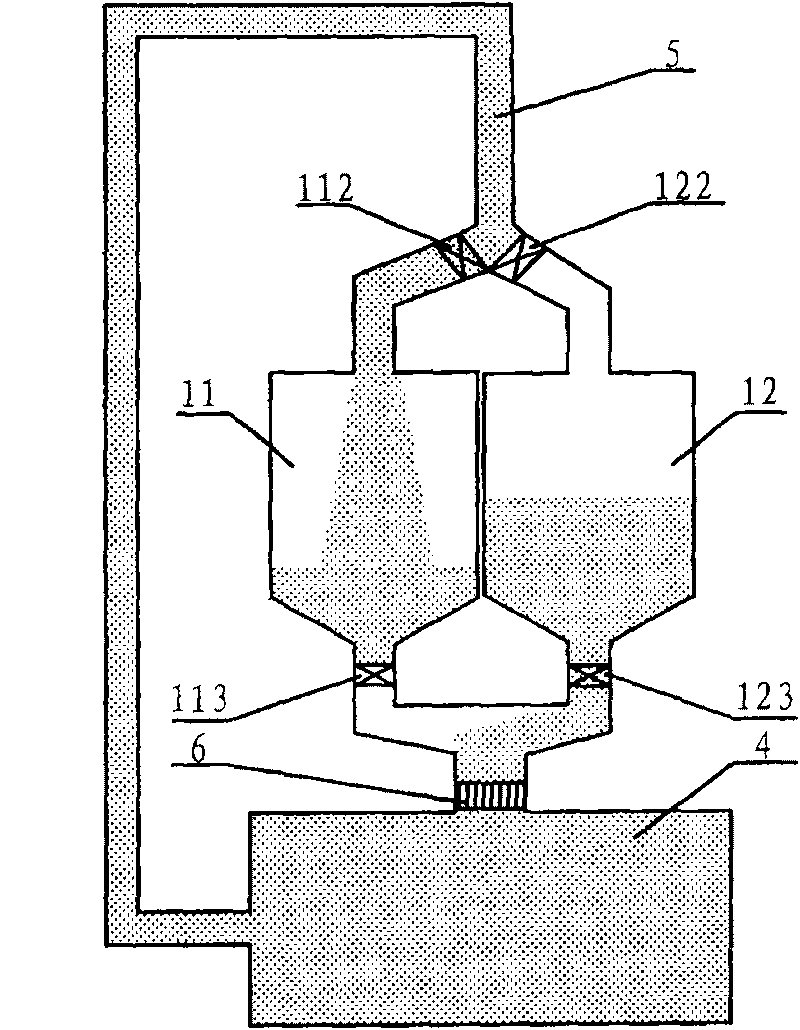

[0022] figure 1 It is a schematic structural diagram of an embodiment of the circulating grinding and dispersing device of the present invention. Such as figure 1 As shown, the main structure of this embodiment is a grinding cylinder 4, a material circulation pipe 5 and a storage cylinder for storing materials. In this embodiment, the storage cylinder includes two outer material cylinders, specifically a first outer material cylinder 11 and a second outer material cylinder 12 . The feeding ports of the grinding cylinder 4 are all connected to the junction of the discharge port of the first outer material cylinder 11 and the discharge port of the second outer material cylinder 12, for feeding from the first outer material cylinder 11 or the second outer material cylinder 12. The materials output fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com