Method for processing polishing cloth surface texture flow passage

A processing method and polishing cloth technology, which are applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems affecting the surface smoothness and surface hardening of the wafer, reduce scratches, improve the smoothness, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

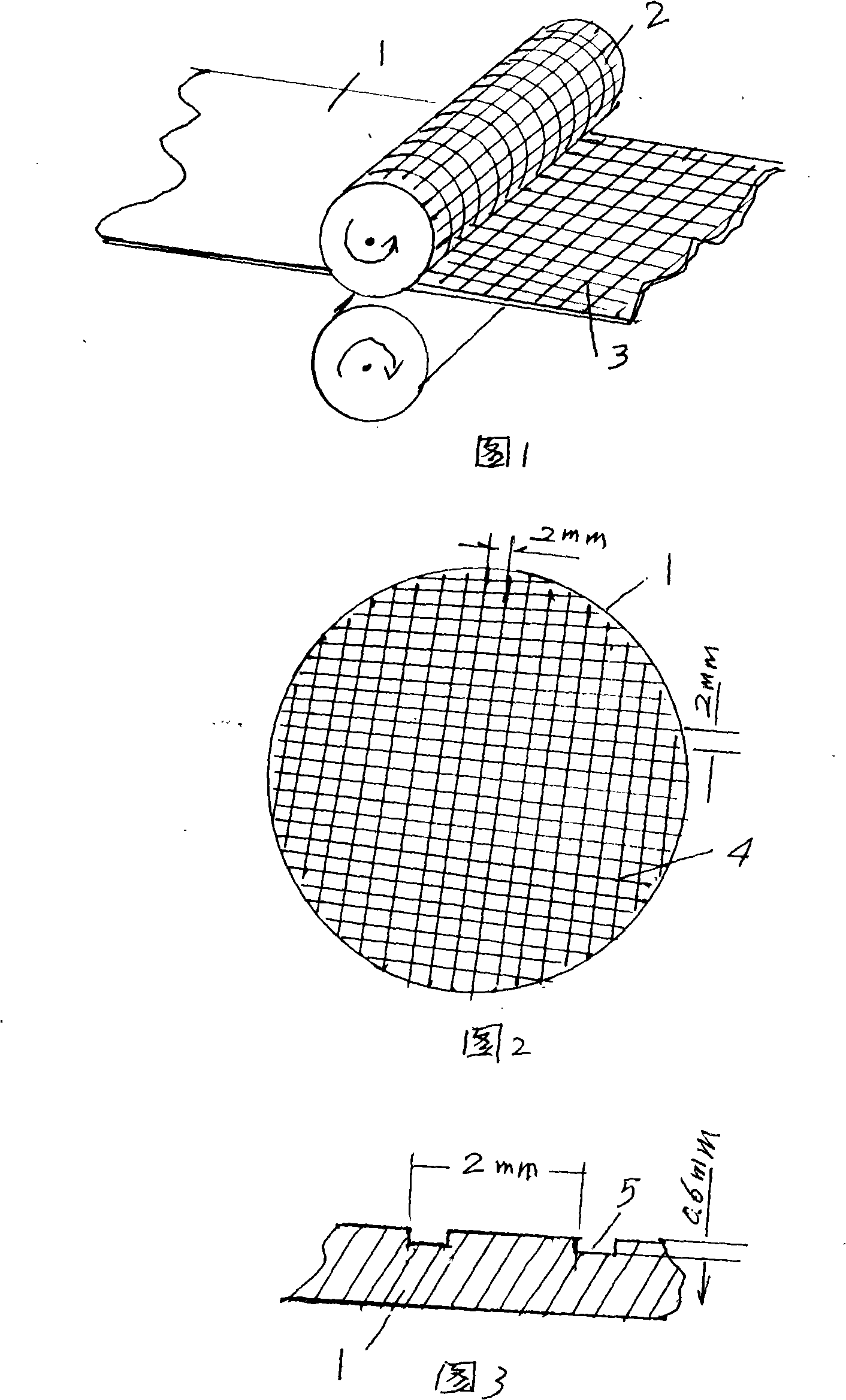

[0016] As shown in FIG. 1 , a method for processing a textured flow channel on the surface of a polishing cloth uses a hot pressing method to press a desired textured flow path on the surface of the polishing cloth.

[0017] The above-mentioned hot pressing method first arranges the polishing in the high-frequency electromagnetic field between the upper and lower electrodes, so that the internal molecules are polarized and move and rub against each other, so as to generate heat by themselves, and then the surface of the polishing cloth 1 is placed on the pressure roller with convex texture. 2. The reticulated flow channel formed under rolling.

[0018] In the above-mentioned hot pressing method, firstly, the temperature of the convex-textured pressing roller used is raised, and then under the condition of high temperature and high pressure, the convex-textured pressing roller rolls on the surface of the polishing cloth to form the surface textured flow channel 3 .

[0019] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com