Gantry type light shield cleaning device

A cleaning device and gantry-type technology, applied in the field of gantry-type cleaning photomask devices, can solve the problems of no air knife device, weak cleaning air, limited effect, etc., to avoid close contact, avoid multiple contacts, The effect of high cleaning uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

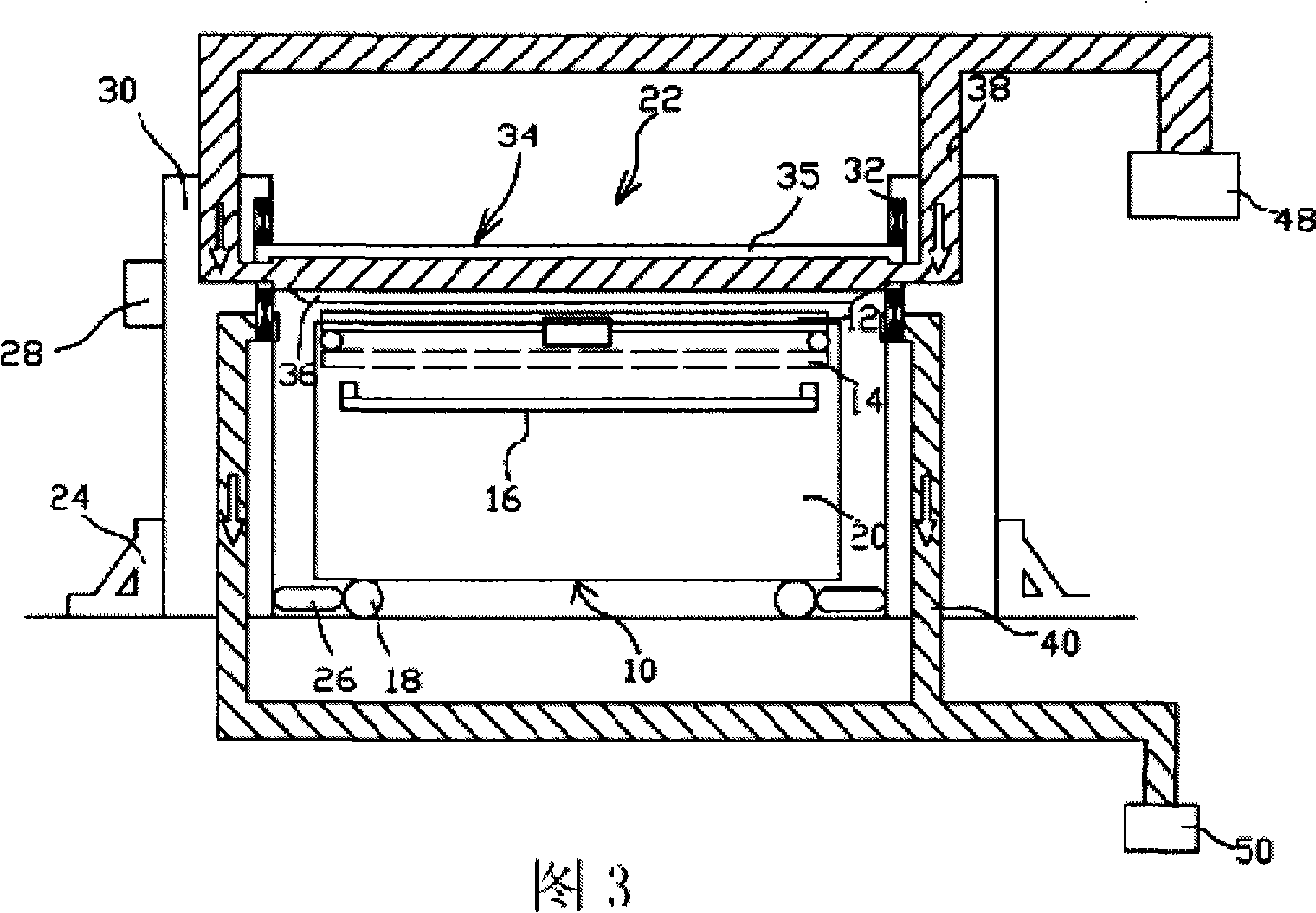

[0049] The invention is a gantry-type photomask cleaning device, which is designed for cleaning particles or impurities on the photomask, and can replace the conventional manual cleaning method, so that the photomask is not easy to be damaged, and the semiconductor manufacturing process can be used during output higher efficiency can be achieved.

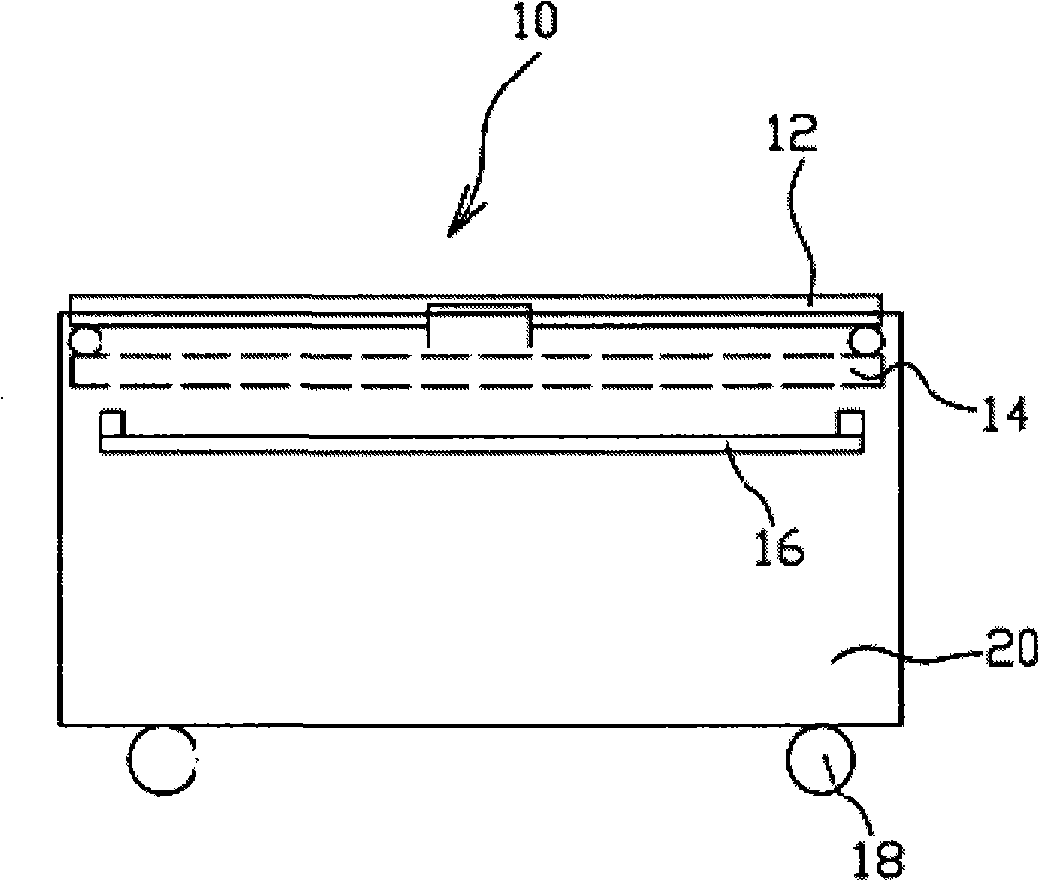

[0050] Refer to attached figure 1 , one embodiment of the prior art. As far as the conventional technology is concerned, there is a photomask carrying device 10, which includes a photomask support platform 14, which can provide a place for placing the photomask 12; the larger the area of the support platform 14, the larger the size of the photomask 12. Larger accommodation locations can also be provided.

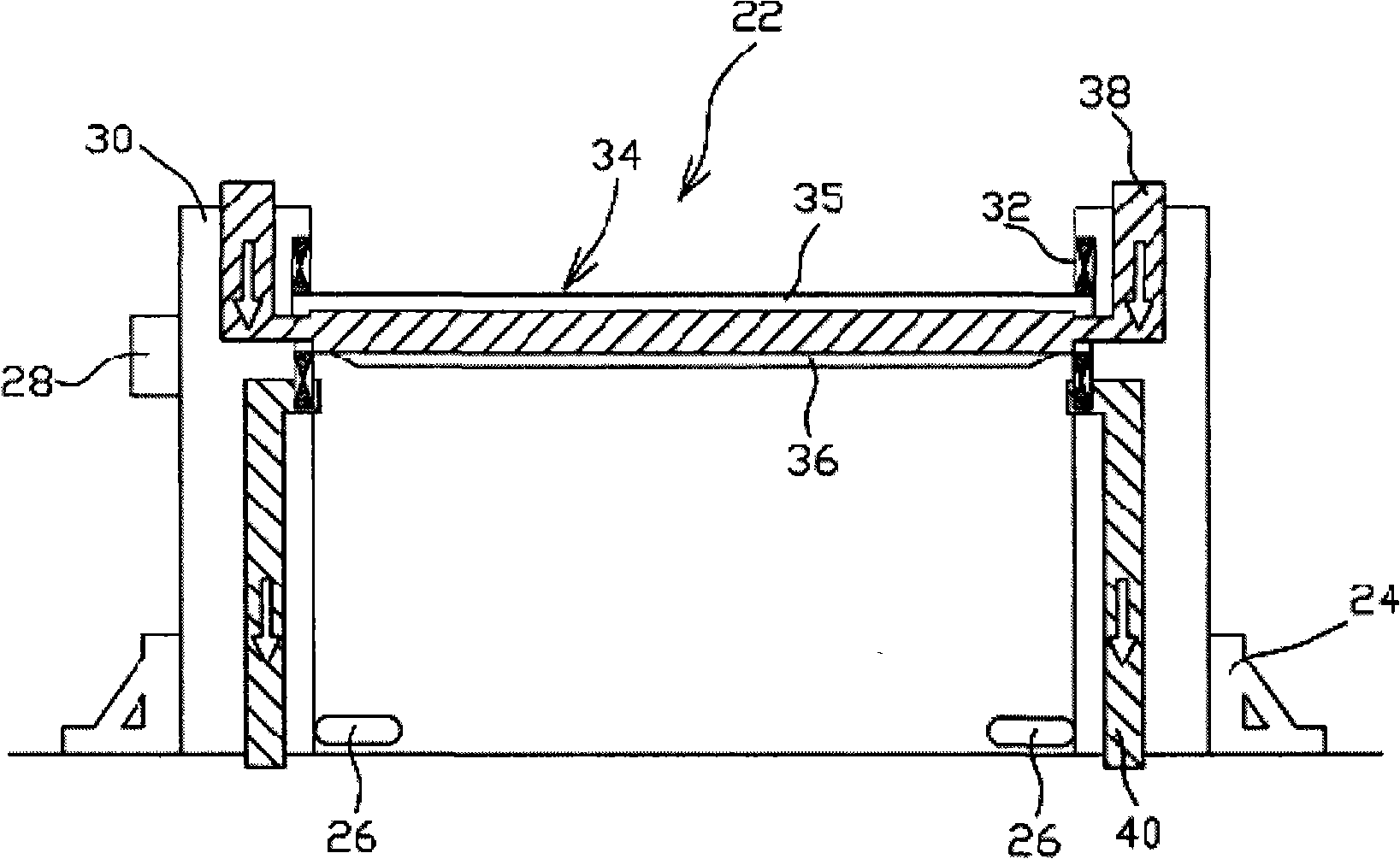

[0051] Refer to attached figure 2, which is one of the preferred embodiments of the present invention. The gantry-type photomask cleaning device 22 of the present invention includes two supporting devices 30 separately plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com