Induction heating method and apparatus for axis-shaped component with raised line

A technology of induction heating and components, applied in induction heating, coil devices, etc., can solve the problems of rising time cost, difficult installation and operation, rising construction cost, etc., and achieve the effect of suppressing cost rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

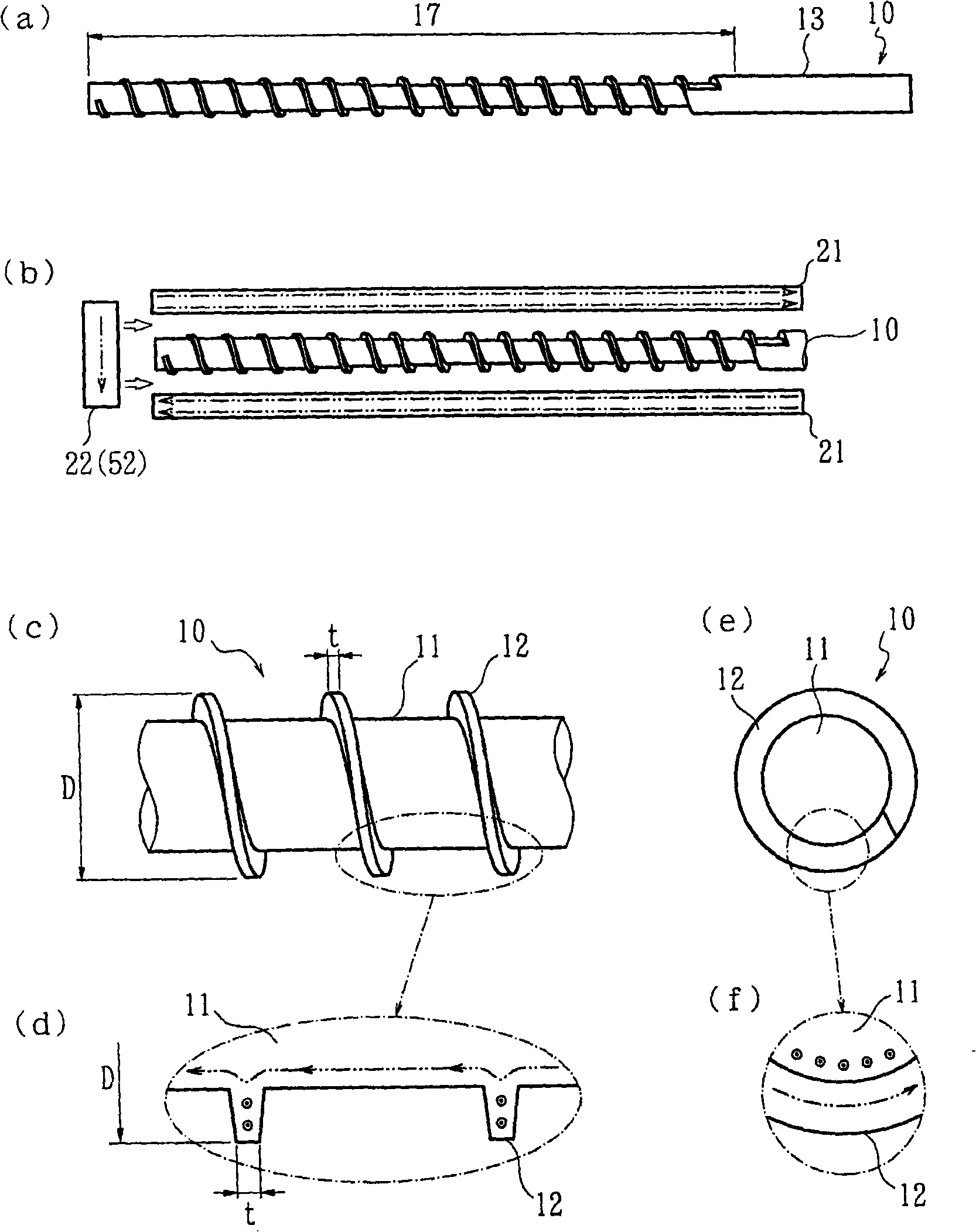

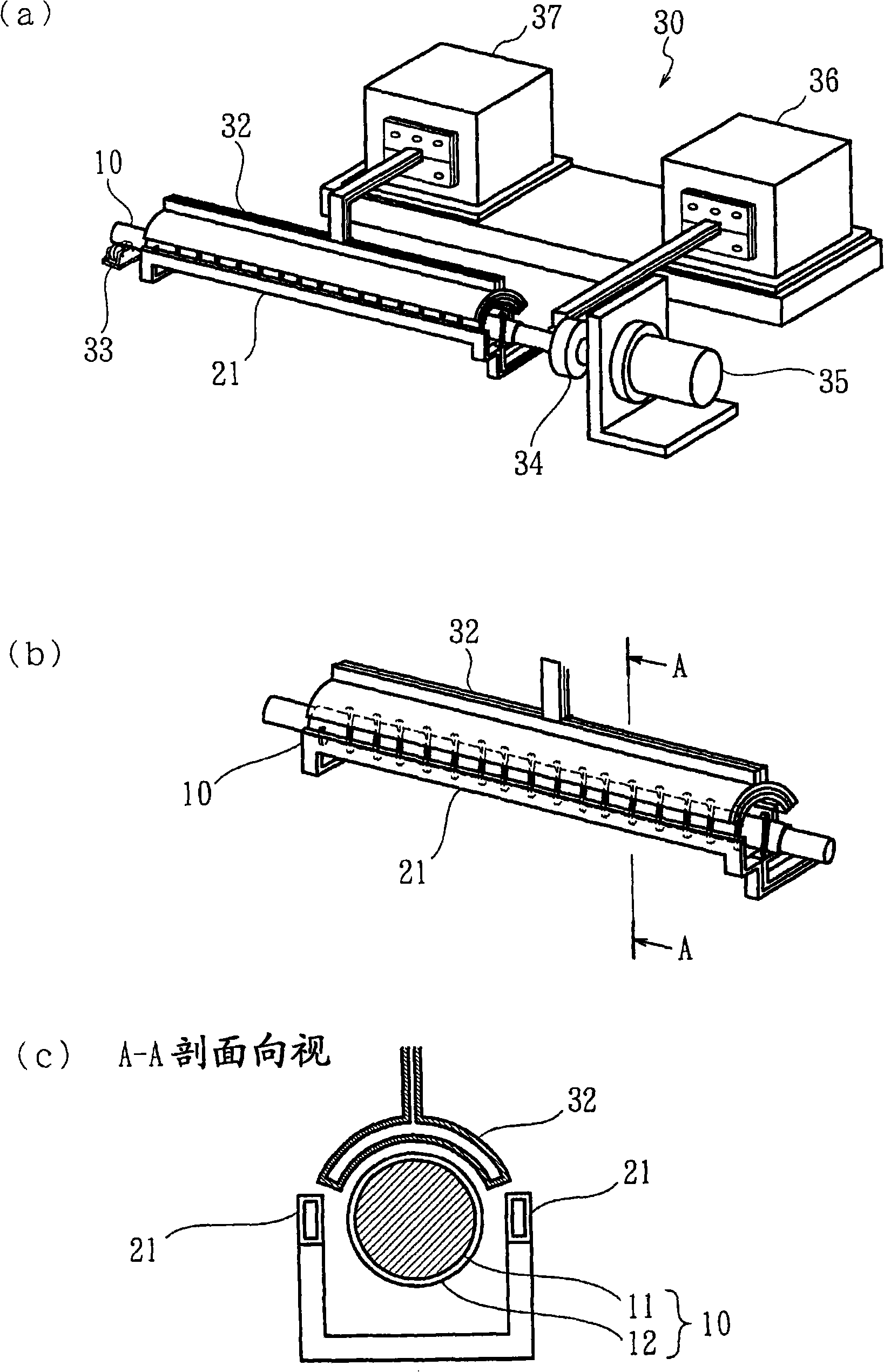

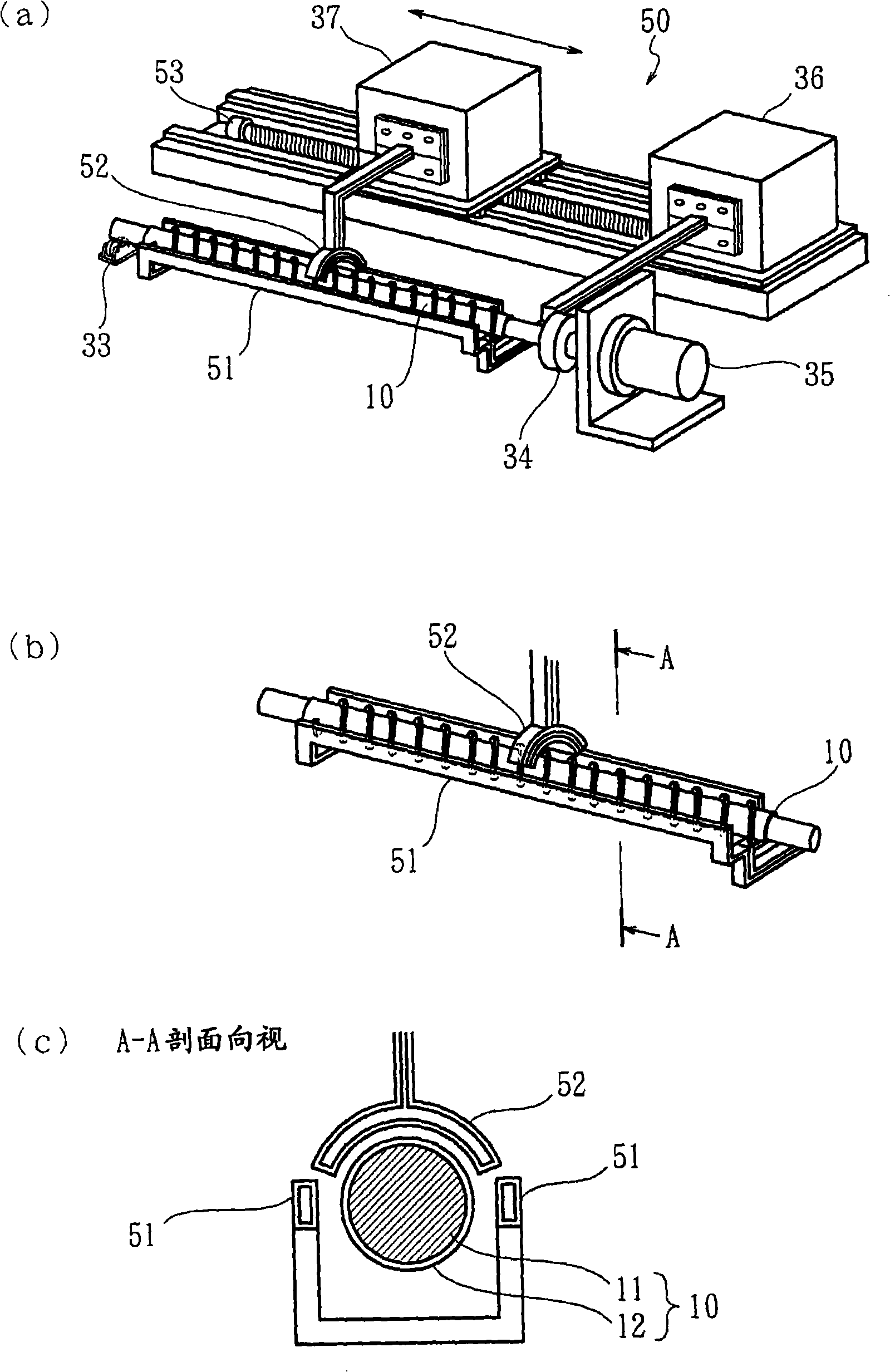

[0148] The specific structure of Embodiment 1 of the induction heating method and apparatus for a shaft-shaped member with protrusions of the present invention will be described with reference to the drawings. Figure 7 It is a plan view of the convex shaft-shaped member 10 whose shaft diameter changes. use image 3 The induction heating device 50 feeds the saddle-shaped axial direction to the induction part of the inductor 51 such as Figure 4 (b) It is formed in a zigzag shape, and the relative intervals g2, g3, and g4 are adjusted.

[0149] The configuration and physical properties of the ribbed shaft member 10 are as follows (refer to Figure 5 ).

[0150] Material: SCM410

[0151] Volume resistivity ρ=80(μΩ-cm)

[0152] Specific permeability μ=1 (ρ, μ are in the temperature region exceeding the magnetic transition point)

[0153] Material of the film layer coated in the previous process: Ni self-fluxing alloy (JIS SNFi2)

[0154] Film thickness covered ...

Embodiment 2

[0184] The specific structure of Embodiment 2 of the induction heating method and apparatus for a shaft-shaped member with protrusions of the present invention will be described with reference to the drawings. Figure 6 It is a plan view of the convex shaft-shaped member 10 whose shaft diameter changes. Also use here image 3 The induction heating device 50 feeds the saddle-shaped axial direction to the induction part of the inductor 51 such as Figure 4 (b) It is formed in a zigzag shape, and the relative intervals g2, g3, and g4 are adjusted.

[0185] The physical properties of the bar-shaped shaft member 10 are as follows (refer to Figure 6 ).

[0186] Material: SCM410

[0187] Volume resistivity ρ=80(μΩ-cm)

[0188] Specific permeability μ=1 (ρ, μ are in the temperature region exceeding the magnetic transition point)

[0189] Material of the film layer coated in the previous process: Ni self-fluxing alloy (JIS SNFi2)

[0190] Film thickness covered in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com