Preparation method of ground section

A technology of grinding and sanding, which is applied in the field of grinding, to achieve the effect of firm bonding of sanding, stable product quality and high utilization rate of sanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

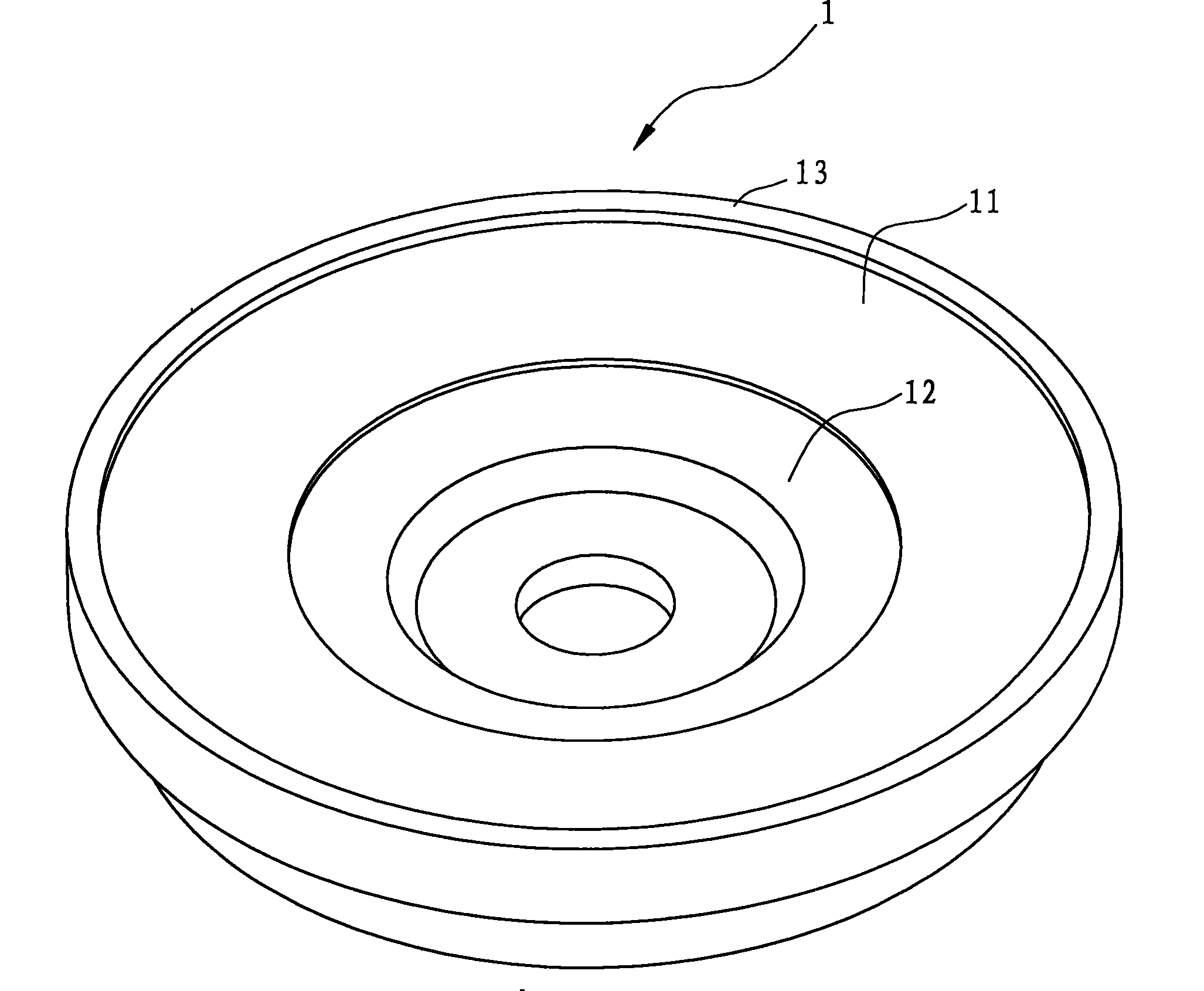

[0038] Example: Reference figure 1 As shown, the platen mold 1 in this embodiment is concave in shape, and has a groove 12 in the middle, a concave first adhesive surface 11 around the groove 12, and a convex surface around the outer edge of the first adhesive surface 11. The raised outer ring wall 13.

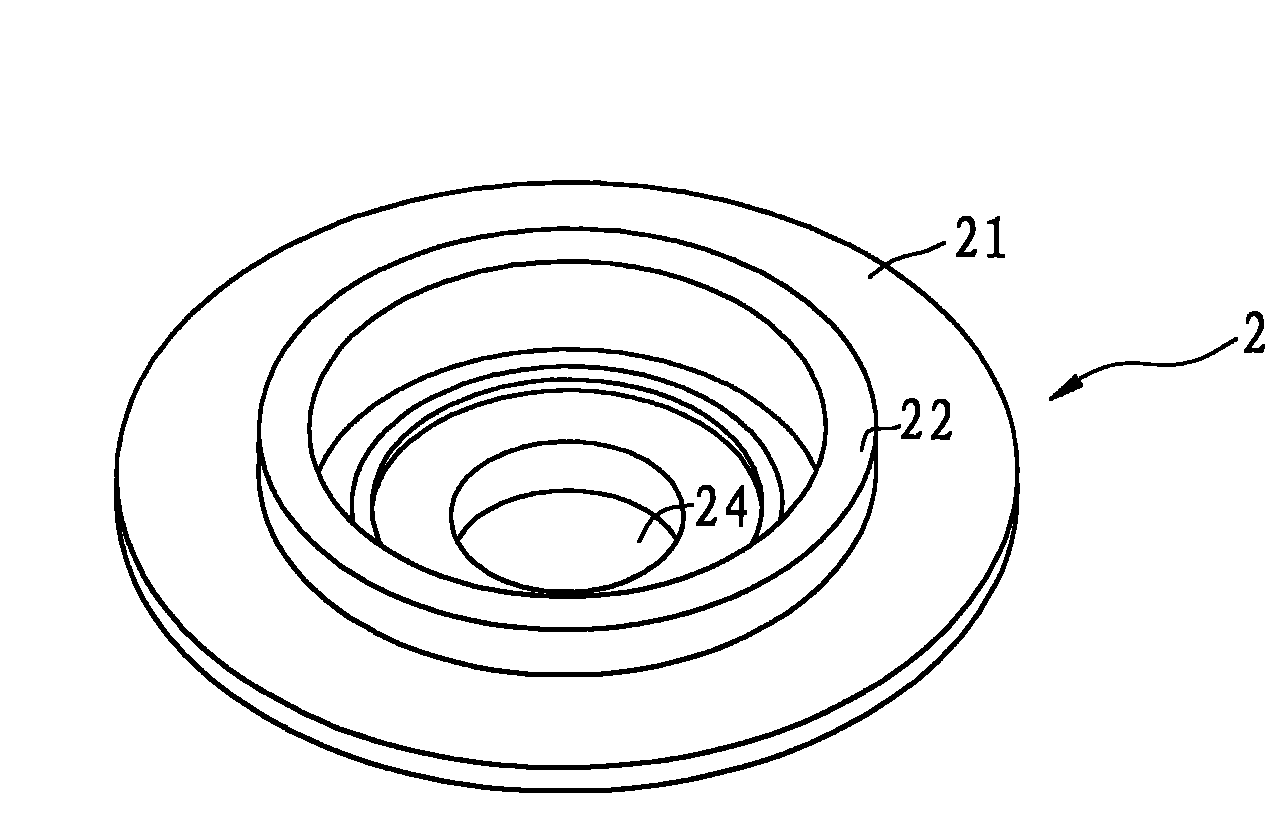

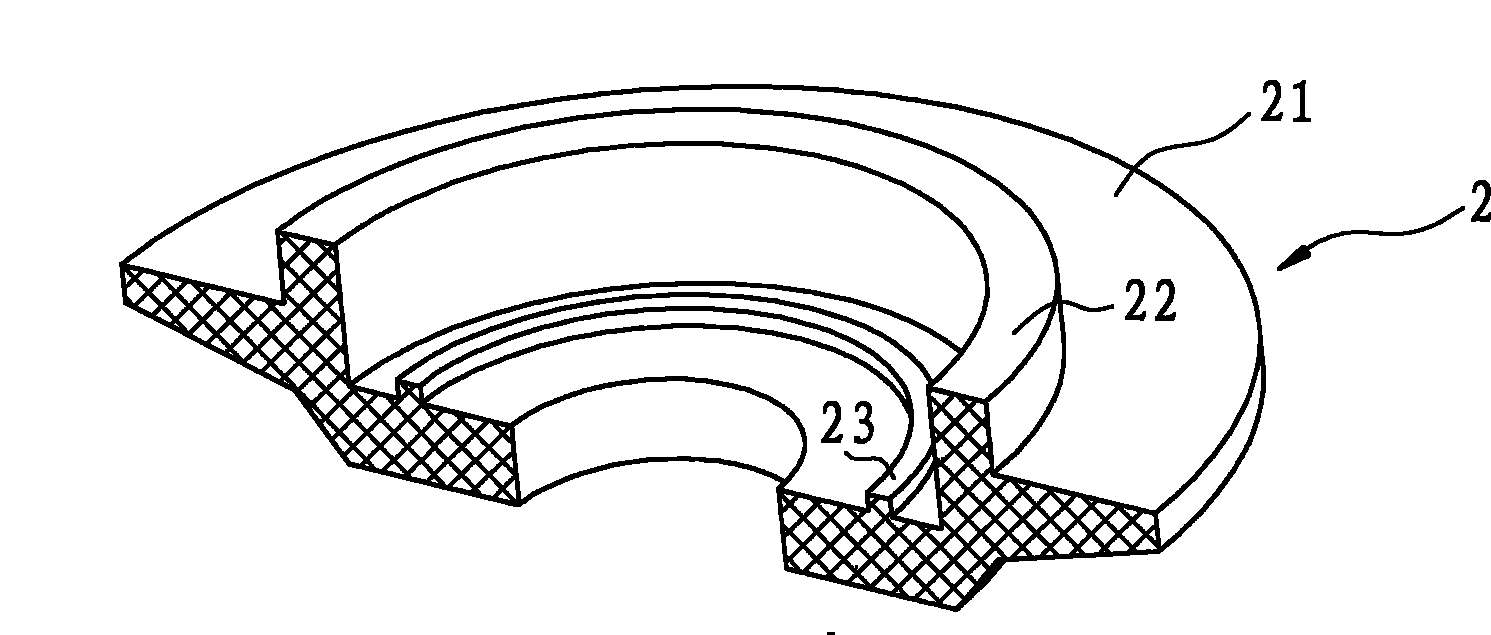

[0039] refer to figure 2 and image 3 As shown, the periphery of the base plate 2 in this embodiment has a second adhesive surface 21, the inner edge of the second adhesive surface 21 has a raised inner ring wall 22, and the middle part has a connecting hole 24, which can be installed on an electric tool , there is also a reinforcing rib 23 around the connection hole to reinforce the connection.

[0040] refer to Figure 4 As shown, the base plate 2 is in the state of the groove 12, the first adhesive surface 11 and the second adhesive surface 21 form an adhesive surface for gluing the sand sheet 3, and the first adhesive surface 11 and the second adhesive surface There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com