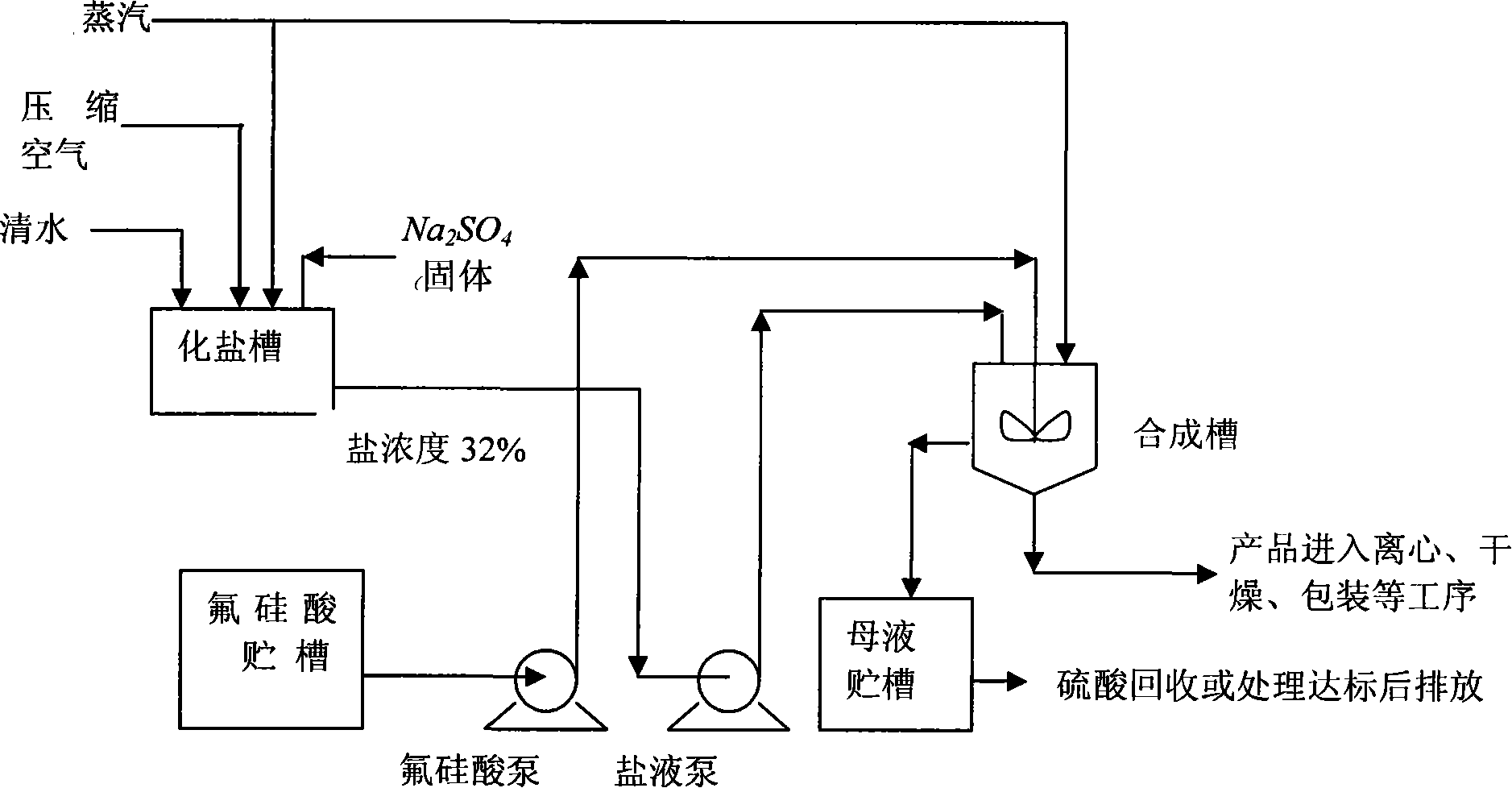

Preparation process of prodan by sodium sulfate method

The technology of sodium fluorosilicate and sodium sulfate is applied in the technical field of producing sodium fluorosilicate by the sodium sulfate method, which can solve the problems of difficulty in controlling the feeding speed, clogging of equipment, increase of silica gel, etc. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

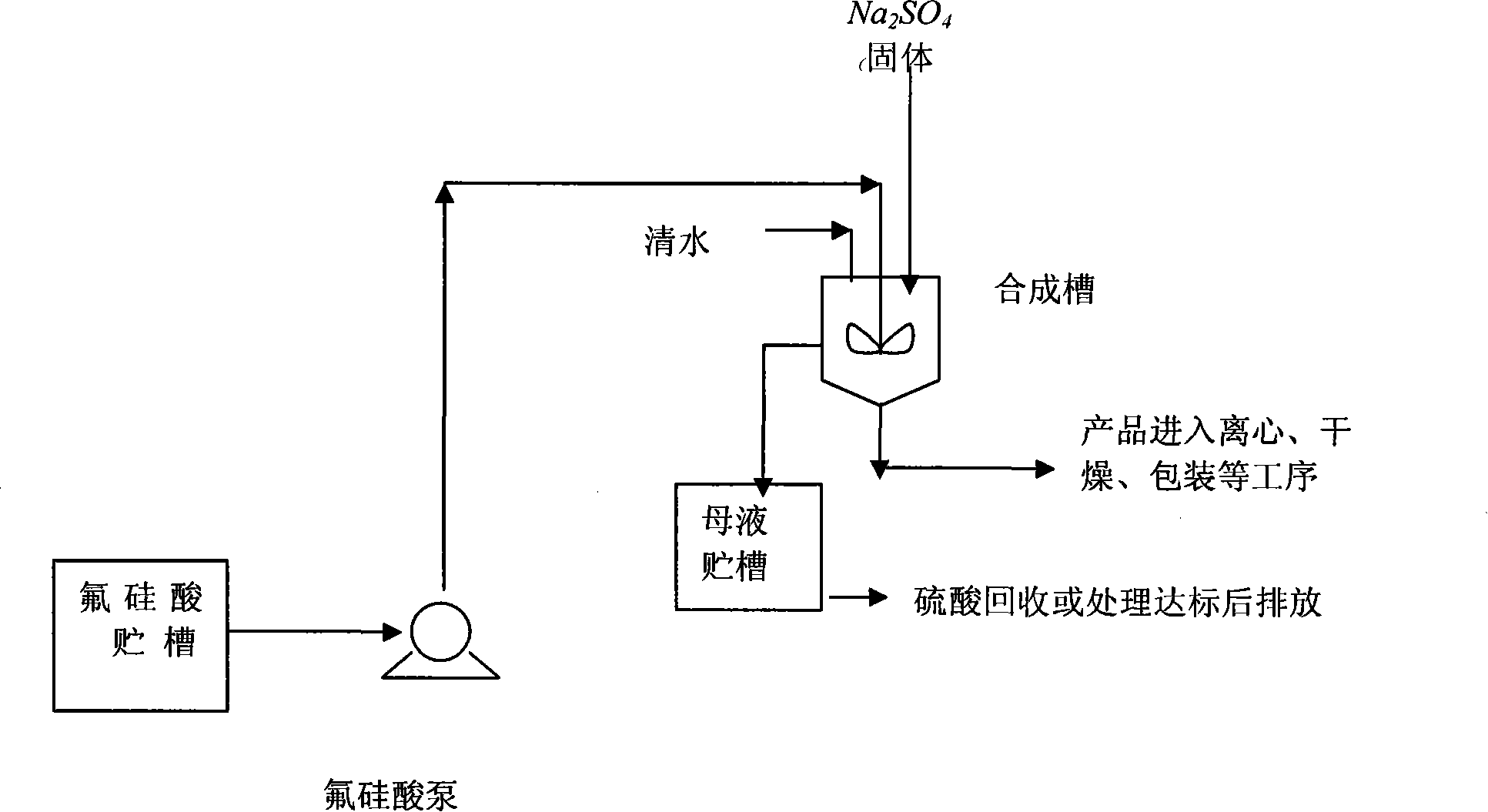

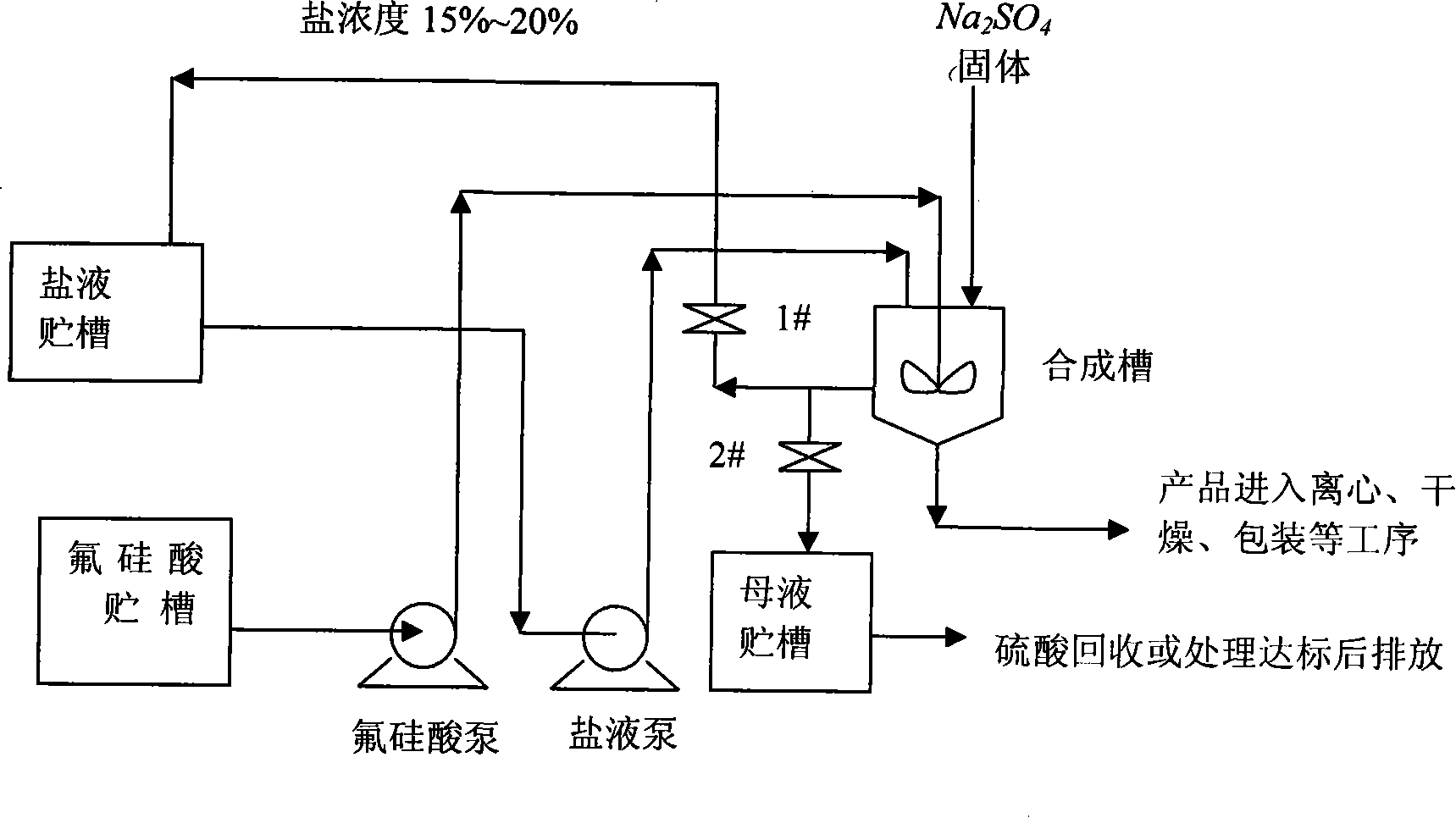

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, be 21m with the brine storage tank volume 3 , the salt concentration is 15% (density 1.135g / ml), the fluosilicic acid concentration is 10% (density 1.082g / ml), and the acid storage capacity is 47m 3 , the synthesis tank volume is 7m 3 as an example.

[0041] If the ratio of fluosilicic acid to sodium sulfate is 1:1.2, add 4.33m of fluosilicic acid each time 3 , add salt 2.67m 3 , batch synthesis, a total of 9 reactions are required. First in the synthetic tank salt 2.7m 3 , and then discharged into the chemical salt storage tank, take the acid to adjust the salt, and enter 4.33m of fluosilicic acid into the synthesis tank 3 , add salt solution 2.67m 3 After the reaction, continue to add solid sodium sulfate, so that the sodium sulfate content of the mother liquor is 15%. After settling, the mother liquor enters the chemical salt storage tank, and is washed by sodium fluorosilicate and then centrifugally dried. React salt three times like this, wait ...

Embodiment 2

[0042] Embodiment 2, be 34m with the saline solution storage tank volume 3 , salt concentration 16% (density 1.148g / ml), fluosilicic acid concentration 8% (density 1.065g / ml), acid storage capacity 61m 3 , the synthesis tank volume is 10m 3 as an example.

[0043] If the ratio of fluosilicic acid to sodium sulfate is still 1:1.2, add 6.47m of fluosilicic acid each time 3 , add salt 3.53m 3 , Batch synthesis, a total of about 10 reactions are required. First in synthetic tank salt 3.53m 3 , and then discharged into the salt storage tank. Adjust the acid and adjust the salt, and enter 6.47m of fluosilicic acid into the synthesis tank 3 , add salt solution 3.53m 3 After the reaction, continue to add solid sodium sulfate, so that the sodium sulfate content of the mother liquor is 16%. After settling, the mother liquor enters the chemical salt storage tank, and is washed by sodium fluorosilicate and then centrifugally dried. React salt three times like this, wait for the sa...

Embodiment 3

[0044] Embodiment 3, be 44m with the saline solution storage tank volume 3 , the salt concentration is 16%, the fluosilicic acid concentration is 9%, and the acid storage capacity is 78m 3 , the synthesis tank volume is 12m 3 as an example.

[0045] If the ratio of fluosilicic acid to sodium sulfate is 1:1.1, add 7.65m of fluosilicic acid each time 3 , add salt 4.35m 3 , intermittent synthesis, a total of 10 reactions are required. First in the synthetic tank salt 4.35m 3 , and then discharged into the salt storage tank. Take fixed acid and adjust salt, and enter 7.65m of fluosilicic acid into the synthesis tank 3 , add salt solution 4.35m 3 After the reaction, continue to add solid sodium sulfate, so that the sodium sulfate content of the mother liquor is 16%. After settling, the mother liquor enters the chemical salt storage tank, and is washed by sodium fluorosilicate and then centrifugally dried. React salt four times like this, wait for the salt solution tank to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com