Camera module group and its assembled method and portable electronic device

A technology of a camera module and an assembly method, which is applied in radiation control devices, installations, televisions, etc., can solve the problems of increasing the volume of the camera module, the large volume of the camera module, and poor anti-interference ability, and achieves reduced attenuation and anti-interference. The effect of noise performance improvement and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

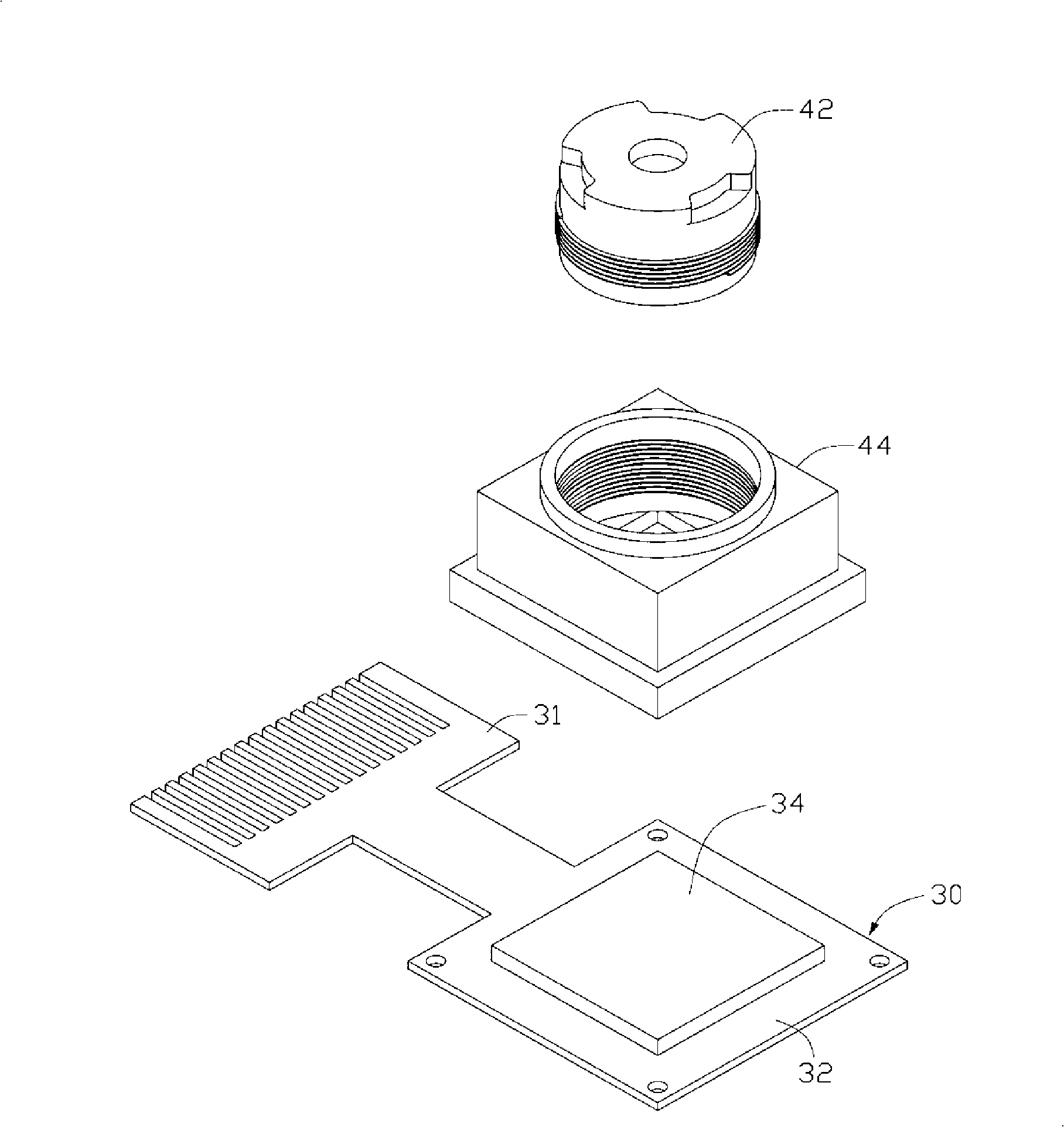

Image

Examples

Embodiment Construction

[0016] Hereinafter, a camera module, an assembly method thereof, and a portable electronic device applied thereto will be described with an embodiment.

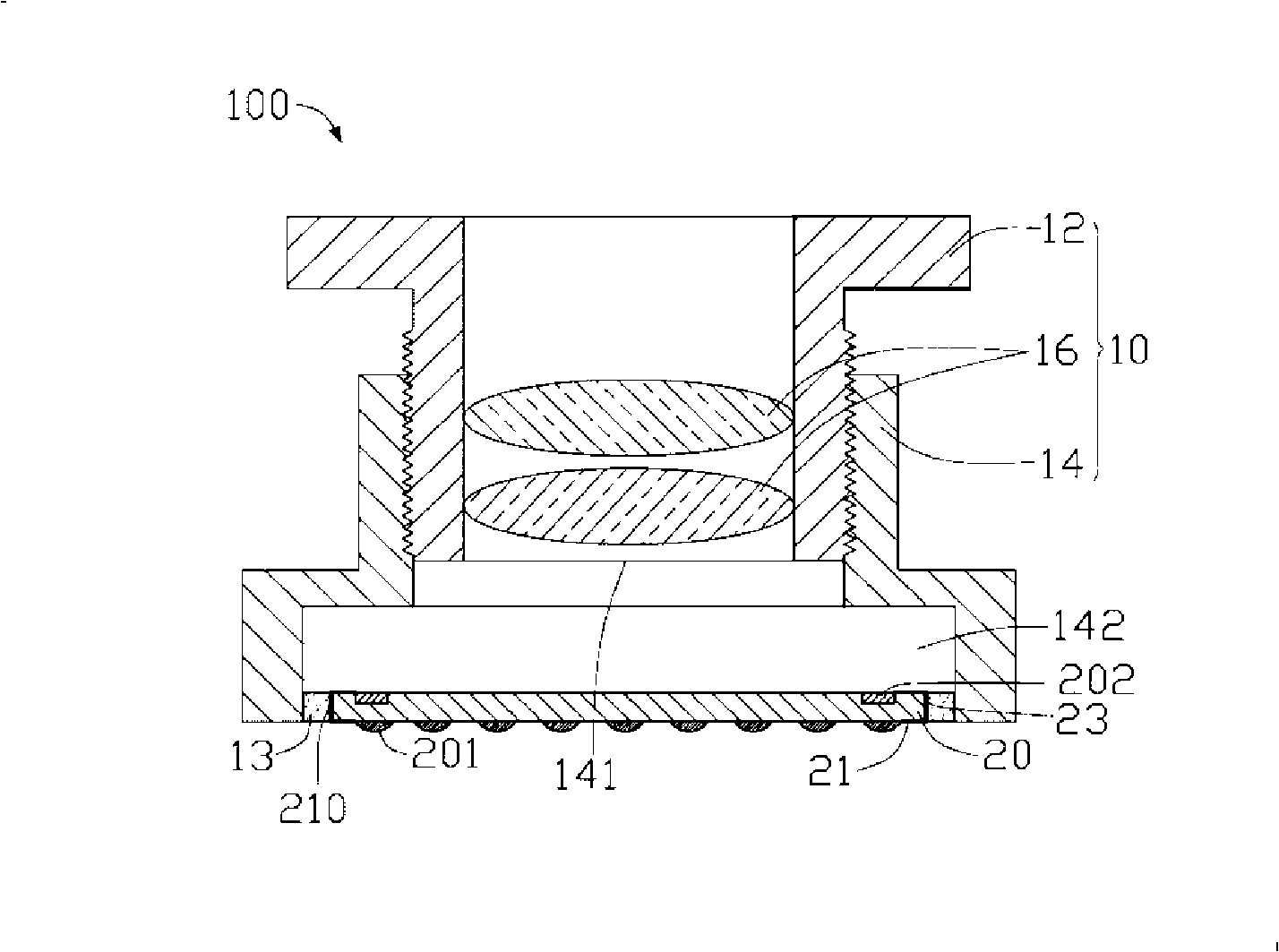

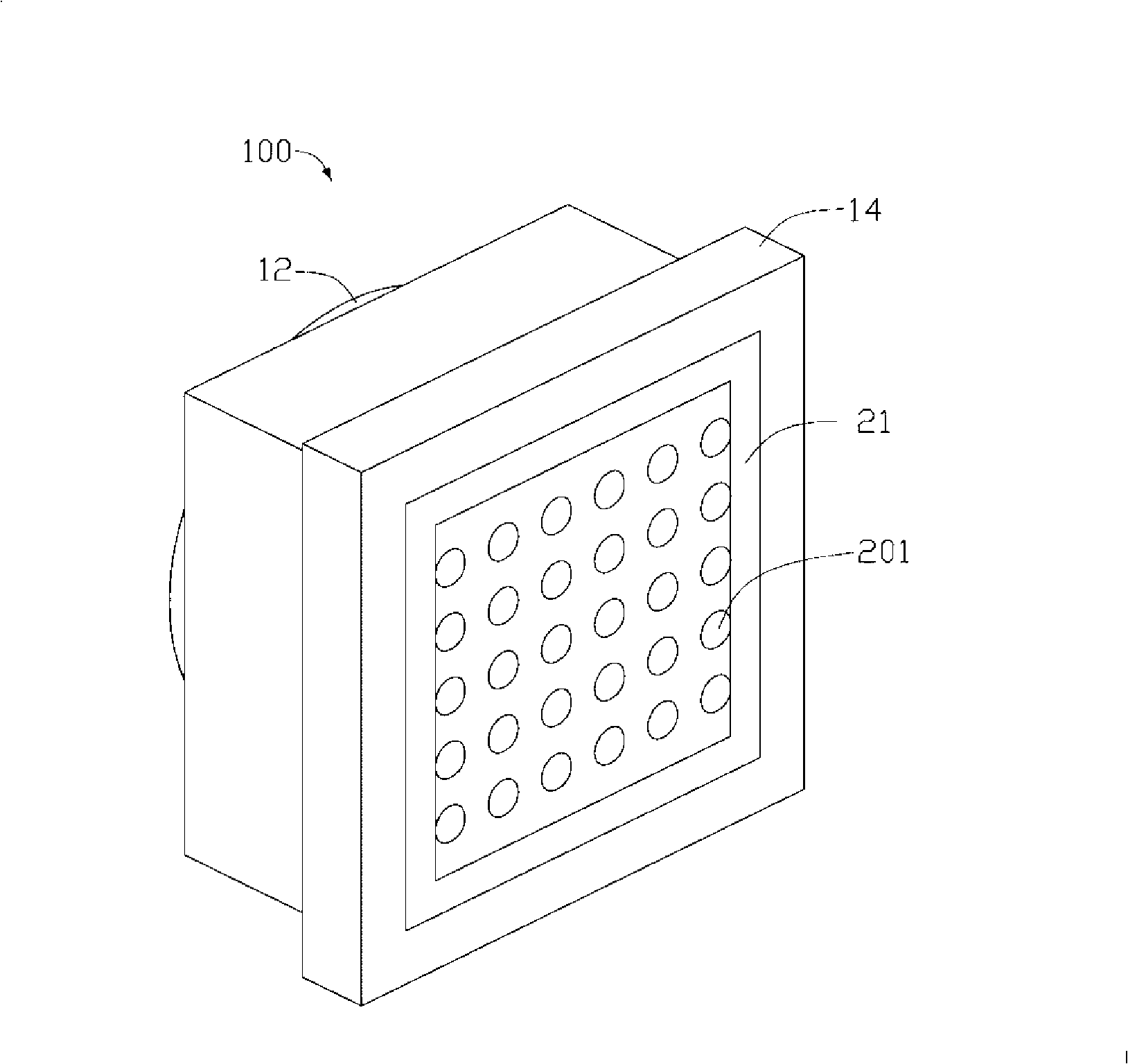

[0017] Please also refer to figure 2 and image 3 , the camera module 100 of the present invention includes an image sensor chip 20 and a lens module 10 .

[0018] The image sensing chip 20 can be a CCD (Charge Coupled Device, Charge Coupled Device sensor) or a CMOS (Complementary Metal Oxide Semiconductor, complementary metal oxide sensor), which is used to convert the optical signal picked up by the lens module 10 into an electrical signal. signal, the top of the image sensor chip 20 is provided with chip pads 202 and traces 23 .

[0019] In this embodiment, the lens module 10 includes a lens barrel 12 , a lens base 14 and a lens group 16 . The mirror base 14 has a first open end 141 and a second open end 142, the lens group 16 is fixed in the lens barrel 12, and the outside of the lens barrel 12 and the inside of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com