Potato peeling equipment

An equipment and potato technology, applied in the field of potato peeling equipment, can solve the problems of large raw materials, poor peeling effect, loss, etc., and achieve the effect of less loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is used to illustrate the peeling method using the peeling equipment provided by the present invention.

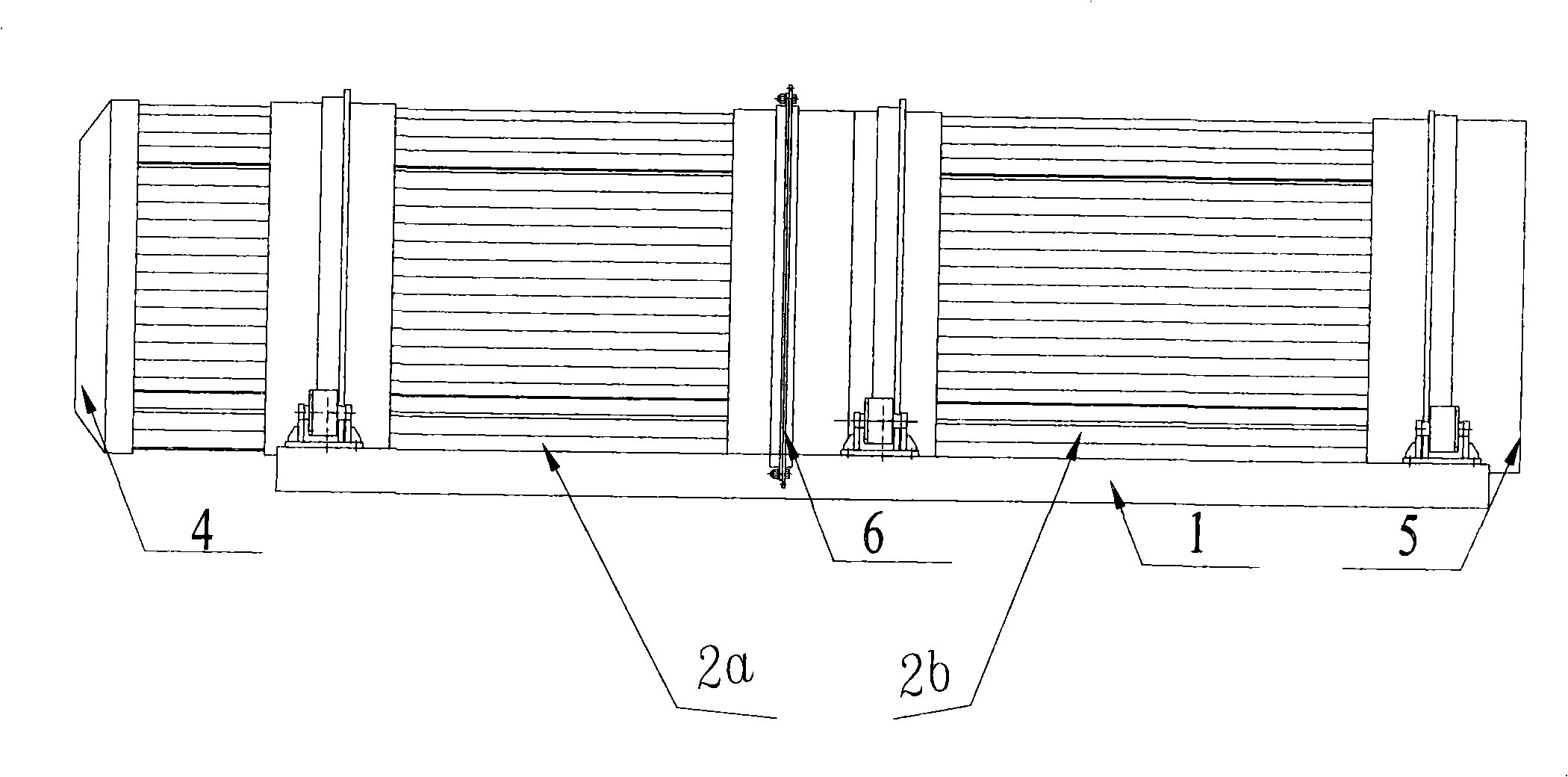

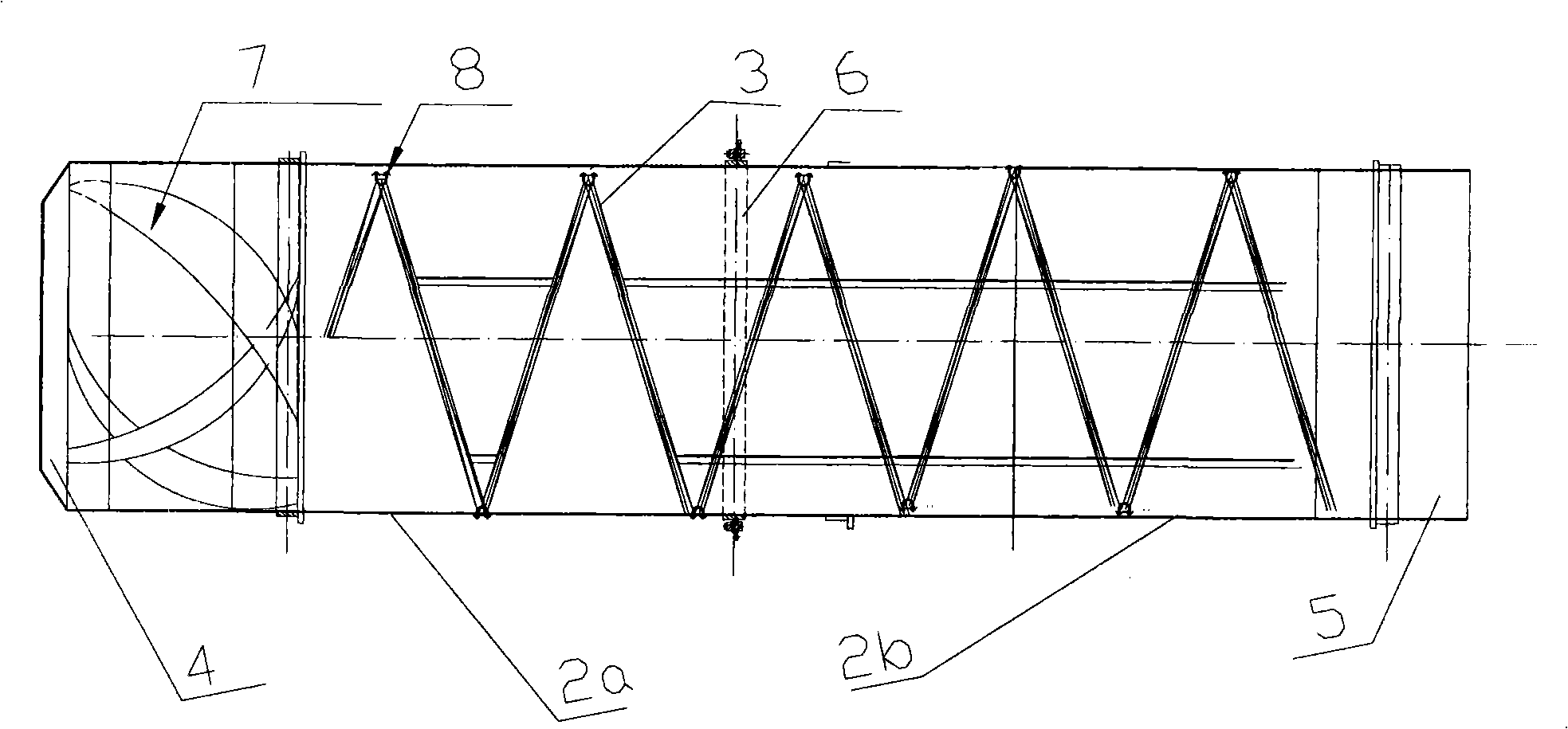

[0027] Prepared as follows figure 1 , 2 and the peeling device shown in 3.

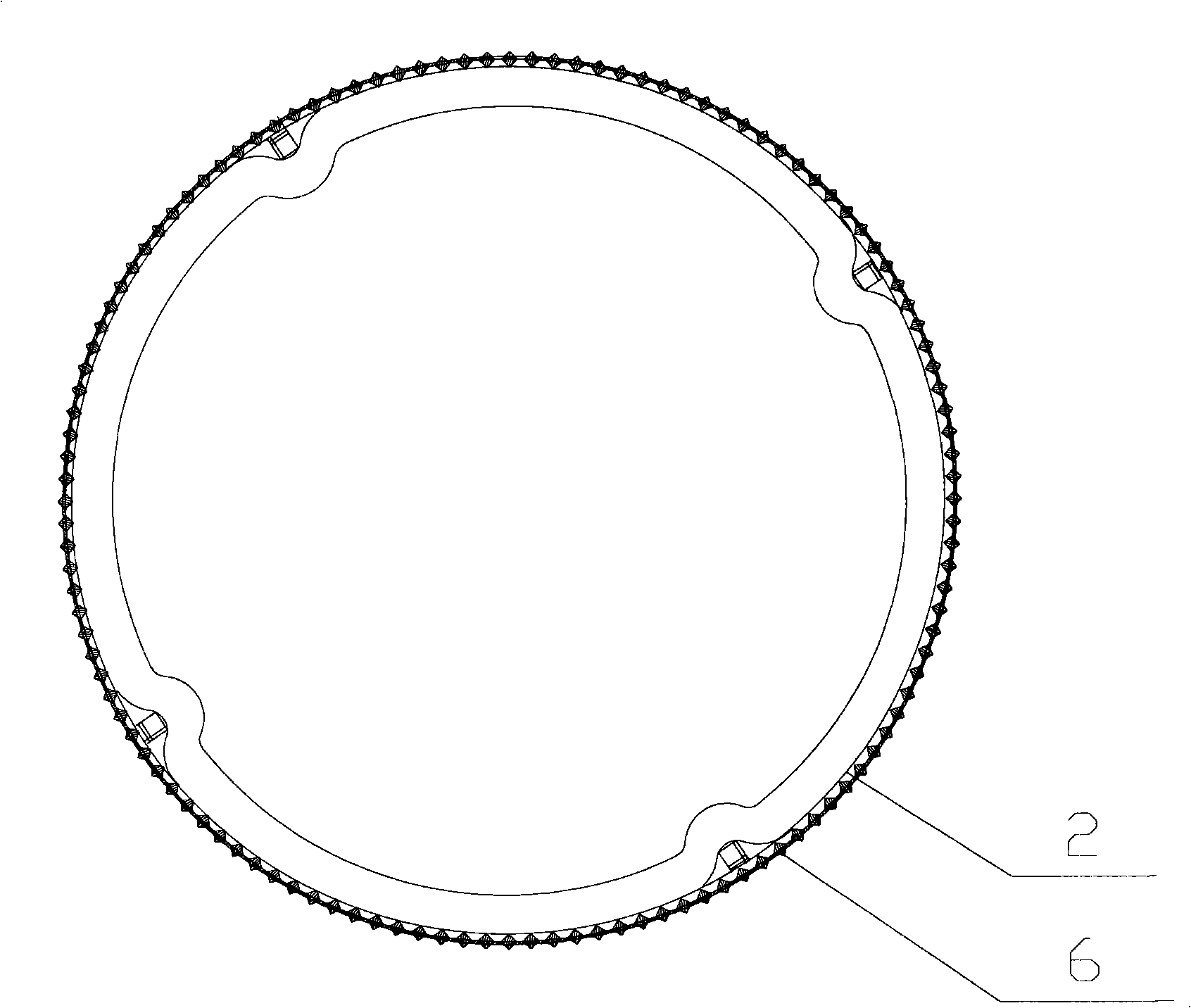

[0028] The drum 2 includes a first segment drum 2a and a second segment drum 2b from top to bottom, the first segment drum 2a and the second segment drum 2b are connected, and the lengths of the first segment drum 2a and the second segment drum 2b are respectively 1.8 meters and 1.6 meters, the second section of drum 2b is provided with a spraying device; the drum 2 is made of steel, with an inner diameter of 1.6 meters; 40 hot-rolled strips with a length of 1.5 meters are fixed on the inner wall of the first section of drum 2a Ribbed steel bars (brand HRB335, nominal diameter 12mm), each hot-rolled ribbed steel bar is parallel to the central axis of the drum, and each hot-rolled ribbed steel bar is distributed at equal intervals along the circumference of the inner wall o...

Embodiment 2

[0031] This embodiment is used to illustrate the peeling effect of the peeling equipment provided by the present invention.

[0032](1) Rinse off the dirt on the surface of cassava A1, cassava A2 and cassava A3 with water respectively, then allow the residual water on the surface to air dry naturally, then weigh them respectively, and record the total weight of cassava A1, cassava A2 and cassava A3 as M1 .

[0033] Count the total number of cassava A1, cassava A2 and cassava A3, randomly select fresh cassava with the same number of roots, wash off the dirt on the surface of the fresh cassava with water, then let the remaining water on the surface dry naturally, and then weigh them separately , record as M2.

[0034] According to the following formula to calculate the loss rate of raw materials (ε 1 ):

[0035] ε 1 =(M2-M1) / M2×100%

[0036] The calculated attrition rate is 3%.

[0037] (2) According to the same method in (1), cassava A1, cassava A2 and cassava A3 are rins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com