Process for preparing undecylenic acid by scission of castor oil

A technology of castor oil and enoic acid, which is applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve problems such as easy coking and lead pollution, achieve less coking, simple manufacturing process, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

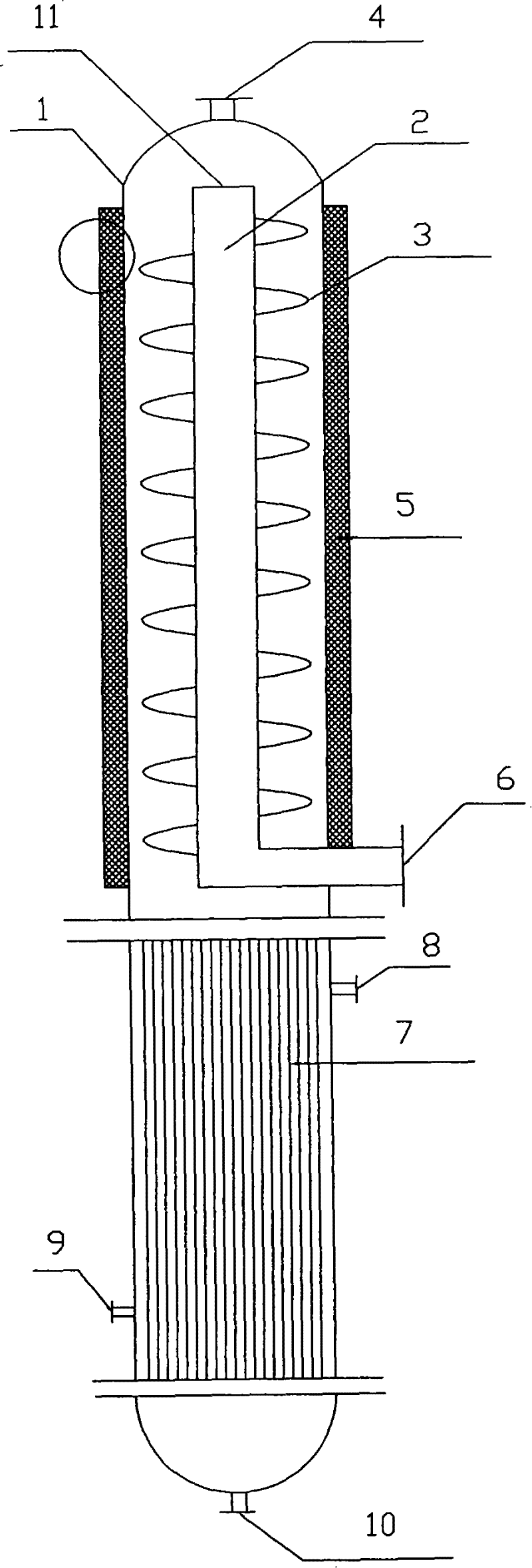

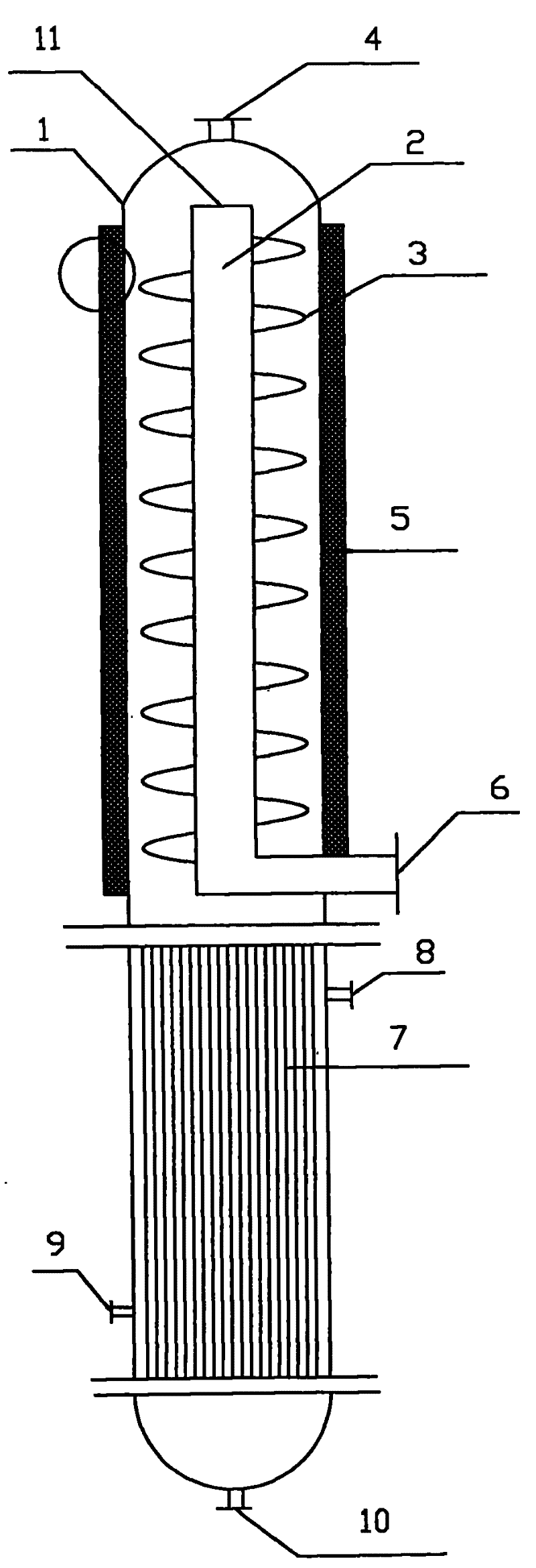

[0010] Embodiment 1, as attached figure 1 Shown schematically, a kind of tower type cracking furnace is made up of the cracking furnace body 1 of the upper part and the condenser 7 that is communicated with the cracking furnace body 1 bottom, and the lower end of the condenser 7 is provided with a cracking material outlet 10, and the cracking furnace body is 1 week The side is an electric heating device 5, and the inside of the cracking furnace body 1 is vertically provided with a feeding pipe 2, and the feeding pipe inlet 6 at the bottom of the feeding pipe 2 is located at the outside of the cracking furnace body 1, and the surrounding side of the feeding pipe 2 is provided with a spiral slice 3. The upper part of the cracking furnace body 1 is provided with a temperature measuring port 4 .

[0011] A method for producing undecylenic acid by cracking castor oil, dissolving castor oil and catalyzer benzoyl peroxide and preheating superheated steam at 150°C and 500°C in a mass...

Embodiment 2

[0013] A method for producing undecylenic acid by cracking castor oil, dissolving castor oil and catalyst benzoyl peroxide and preheating superheated steam at 200°C and 600°C in a mass ratio of 1000:7:1300, by The feeding pipe inlet 6 enters the feeding pipe 2, enters the top of the cracking furnace body 1 from the feeding pipe outlet 11, enters the reaction space along the spiral piece 3, and heats the cracking furnace body 1 on the tower cracking furnace top with the electric heater 5 to Cracking at 600°C produces a mixed gas of undecylenic acid, heptanal and other by-products. The gas flows to the lower end of the cracking tower body 1 and enters the condenser 7 to condense. Undecylenic acid and heptanal products are produced. The yield of undecylenic acid is about 36.5%.

Embodiment 3

[0015] A kind of castor oil cracking method that undecylenic acid is prepared, castor oil and catalyzer benzoyl peroxide are dissolved and matched and the superheated steam that is preheated to 180 ℃ and 550 ℃ is by the mass ratio of 1000:35:1200, by The feeding pipe inlet 6 enters the feeding pipe 2, enters the top of the cracking furnace body 1 from the feeding pipe outlet 11, enters the reaction space along the spiral piece 3, and heats the cracking furnace body 1 on the tower cracking furnace top with the electric heater 5 to Cracking at 550°C produces a mixed gas of undecylenic acid, heptanal and other by-products. The gas flows to the lower end of the cracking tower body 1 and enters the condenser 7 to condense. Undecylenic acid and heptanal products are produced. The yield of undecylenic acid is about 35.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com