Liquid tundish

A tundish and liquid technology, which is applied in the direction of casting melt containers, manufacturing tools, casting equipment, etc., can solve the problems of low production efficiency and poor continuity, and achieve the effects of improving production efficiency, saving energy and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the structure and features of the present invention, the present invention will be described in detail below in combination with preferred embodiments and accompanying drawings. In order to make the structure of the present invention clearer, the actual scale relationship of the drawings may be changed during the drawing process, which should not be construed as a limitation to the patent application.

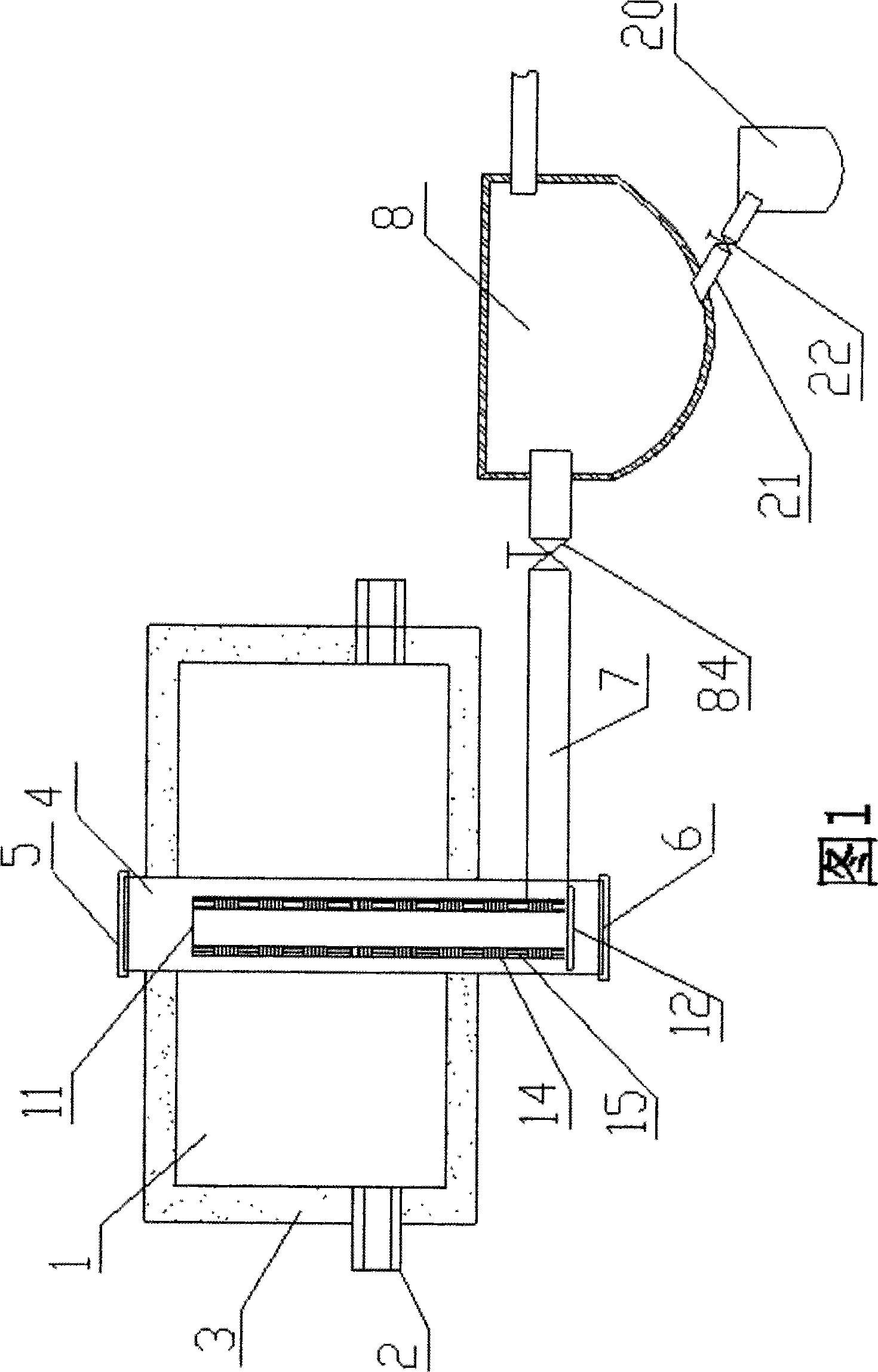

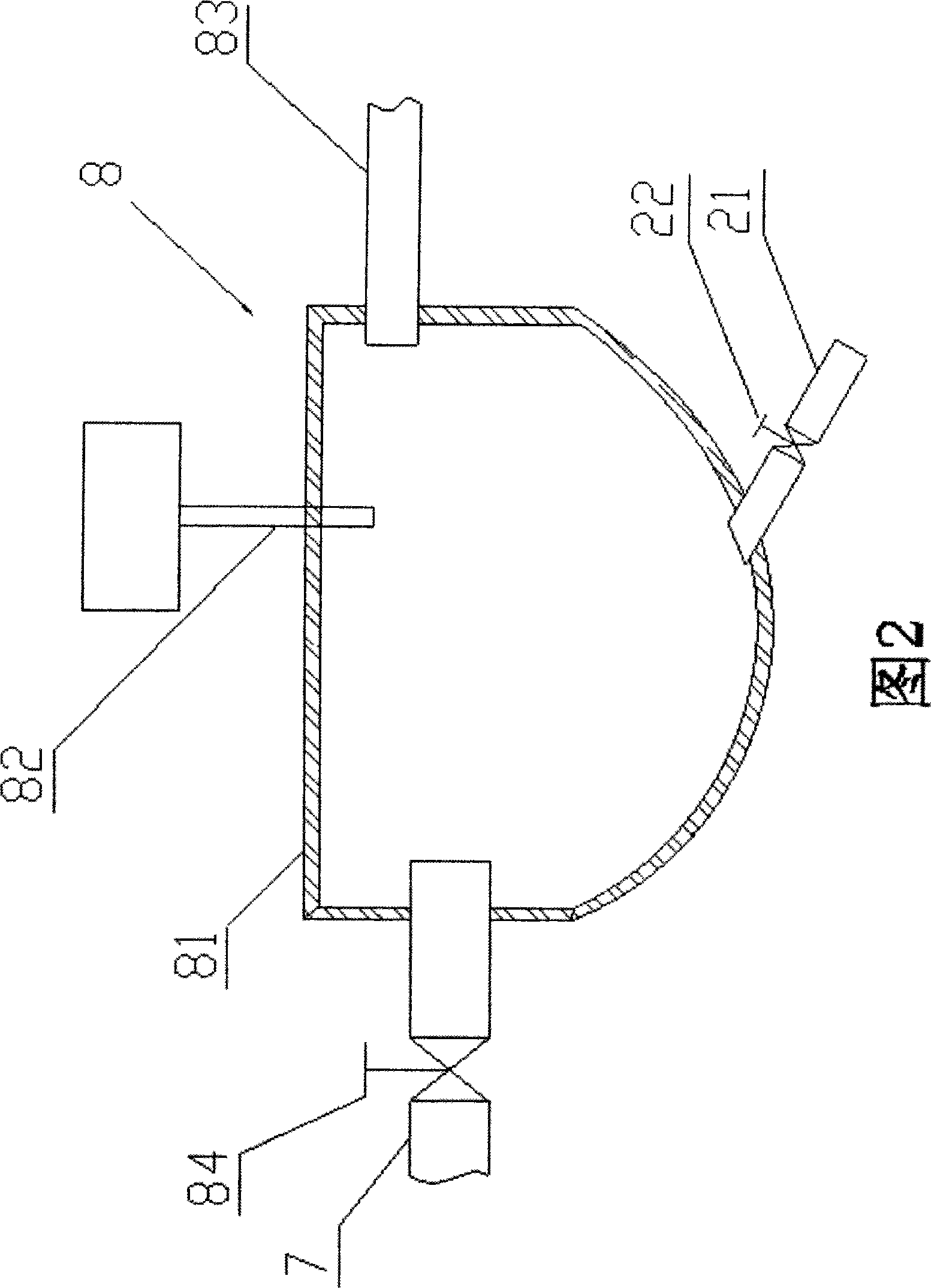

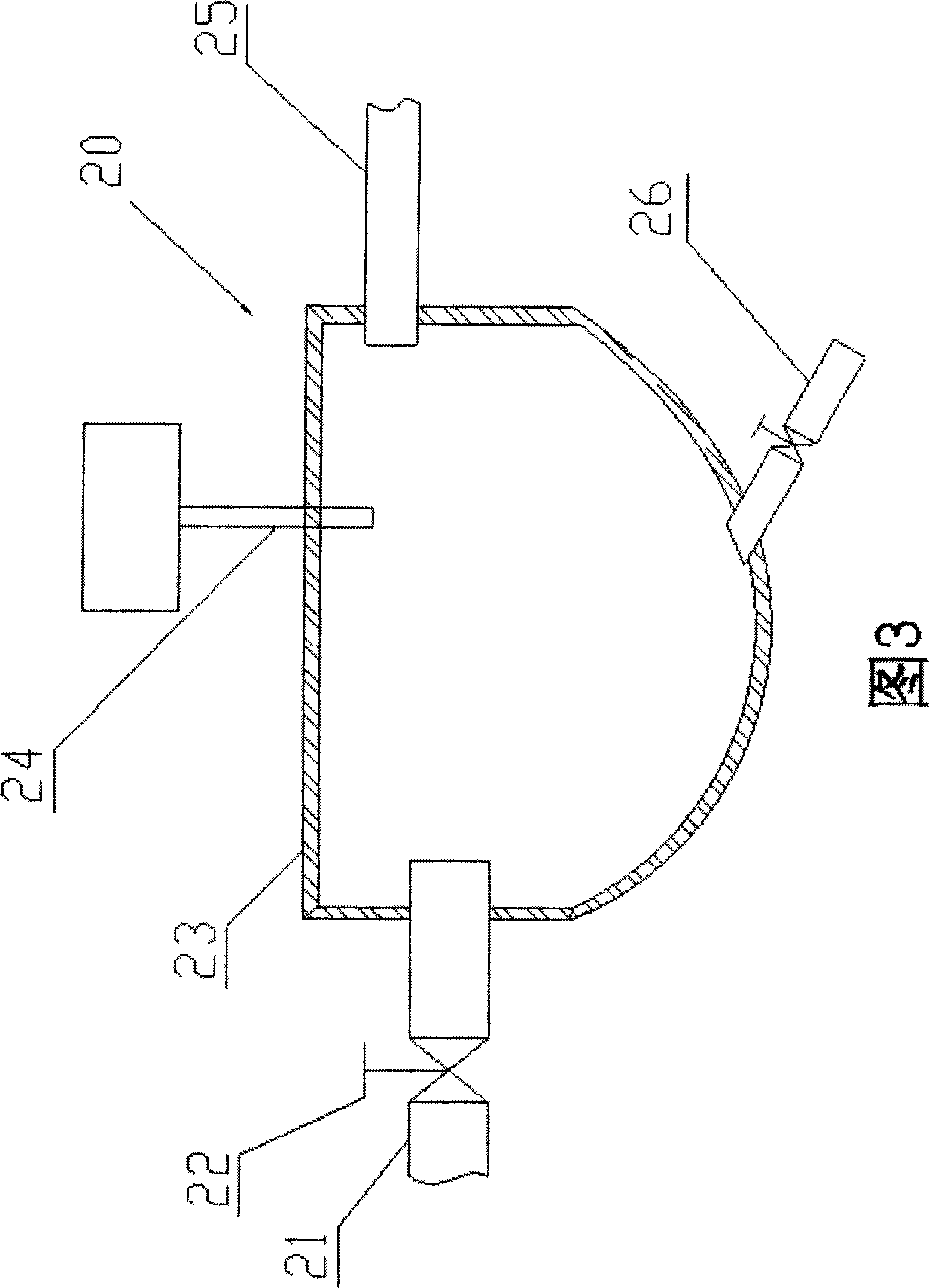

[0030] Such as figure 1 As shown, it is a structural schematic diagram of a metal vacuum smelting reduction device capable of semi-continuous production in the present invention, including a reduction furnace 1, a reduction tank 4, a liquid crystallizer 8 and a liquid tundish 20, wherein:

[0031] The reduction furnace 1 adopts regenerative combustion technology, and is equipped with a furnace body 3 and a burner 2, both of which are prior art and will not be described in detail.

[0032] The reduction tank 4 is vertically arranged in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com