High manganese-containing magnesium-manganese intermediate alloy and preparation

A master alloy, mass percentage content technology, applied in the field of metal material preparation, can solve the problems of difficult preparation of high manganese-containing magnesium-manganese master alloy, reduced manganese solubility, high working temperature, etc., to save energy and labor, and less process , short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

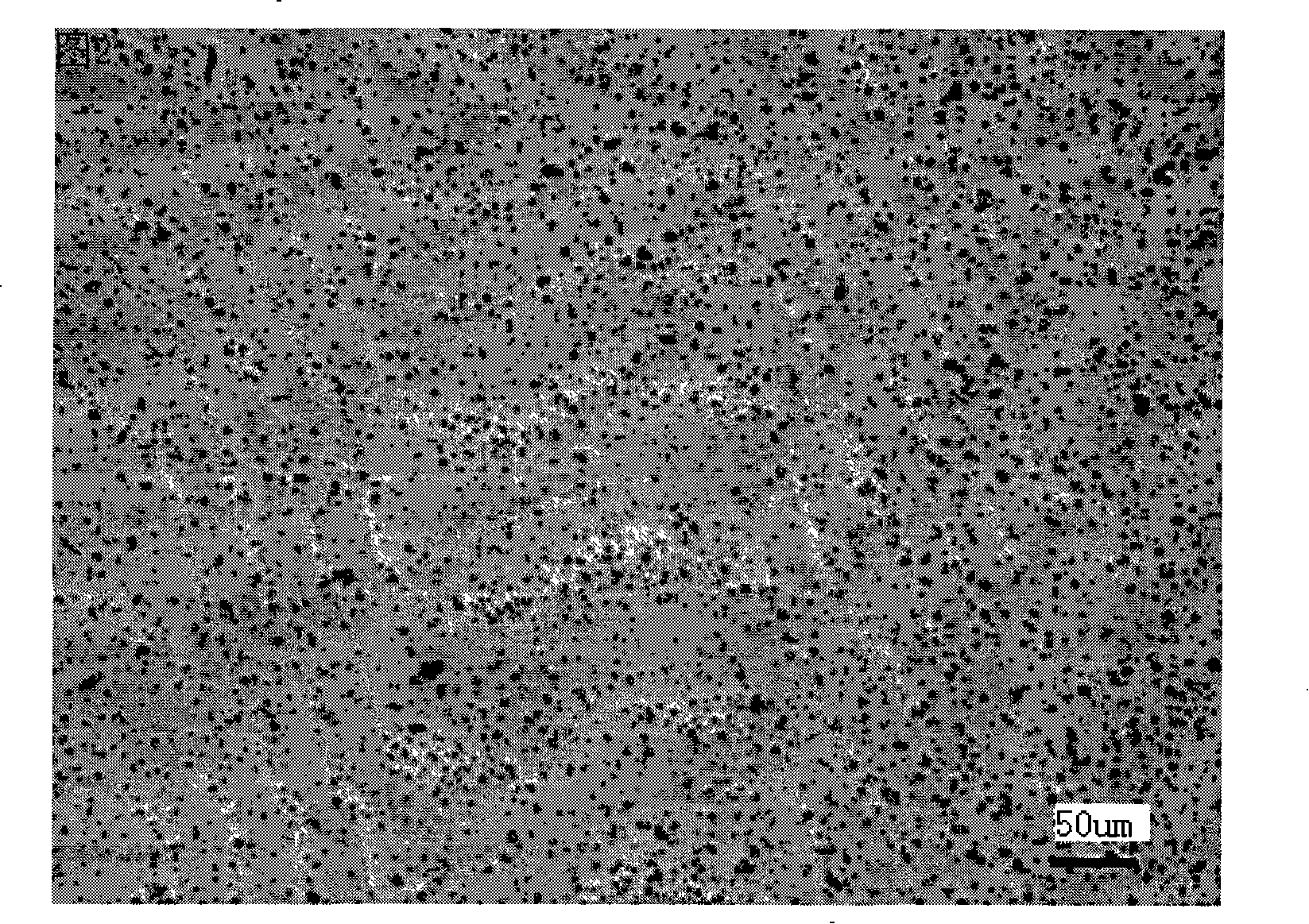

[0028] Get 115 grams of pure magnesium and 11 grams of metal manganese powder, and melt them according to the above method to make a high manganese content magnesium-manganese master alloy. The obtained magnesium-manganese master alloy ingot with high manganese content, the metallographic structure is shown in figure 1 . Sampling was evenly taken at 5 points along the diagonal line of the longitudinal section of the ingot, and tested according to GB / T 1506-2002 to obtain a magnesium-manganese master alloy with an average Mn content of 10.8% (mass percentage) and a high manganese content.

Embodiment 2

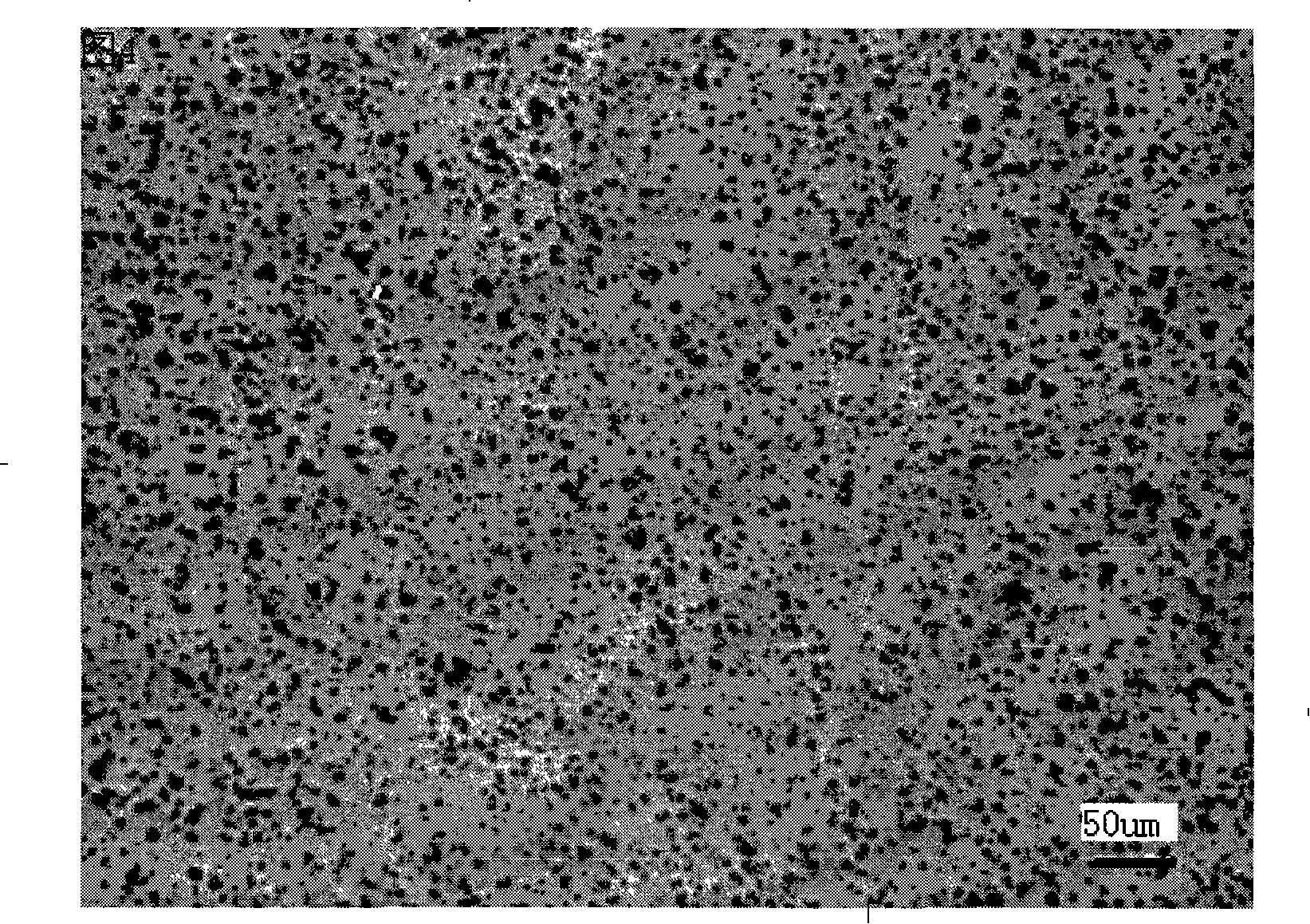

[0030] Get 120 grams of pure magnesium and 13.7 grams of metal manganese powder, melt according to the above-mentioned method and make high manganese content magnesium-manganese master alloy. The obtained magnesium-manganese master alloy ingot with high manganese content, the metallographic structure is shown in figure 2 . Sampling was uniformly taken at 5 points along the diagonal line of the longitudinal section of the ingot, and tested according to GB / T 1506-2002 to obtain a magnesium-manganese master alloy with a high manganese content and an average Mn content of 12.2% (mass percentage).

[0031] in conclusion:

[0032] According to the method described in the patent of the present invention, a magnesium-manganese master alloy with a high manganese content can be prepared with a Mn content of 8-12% (mass percentage). The method is simple to operate, the raw materials and equipment used are common products in the market, and has the characteristics of low cost and suita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com