Multi-element transition metal carbide hybrid reinforced copper-based surfacing layer and preparation method thereof

A transition metal and carbide technology is used in the preparation of copper-based surfacing layers, and in the field of copper-based surfacing layers reinforced by multiple transition metal carbides. The performance of composite materials is degraded, and it is difficult to meet service requirements, etc., to achieve the effect of reducing adverse effects, convenient composition adjustment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a copper-based surfacing layer strengthened by the hybridization of multivariate transition metal carbides. The specific steps are as follows:

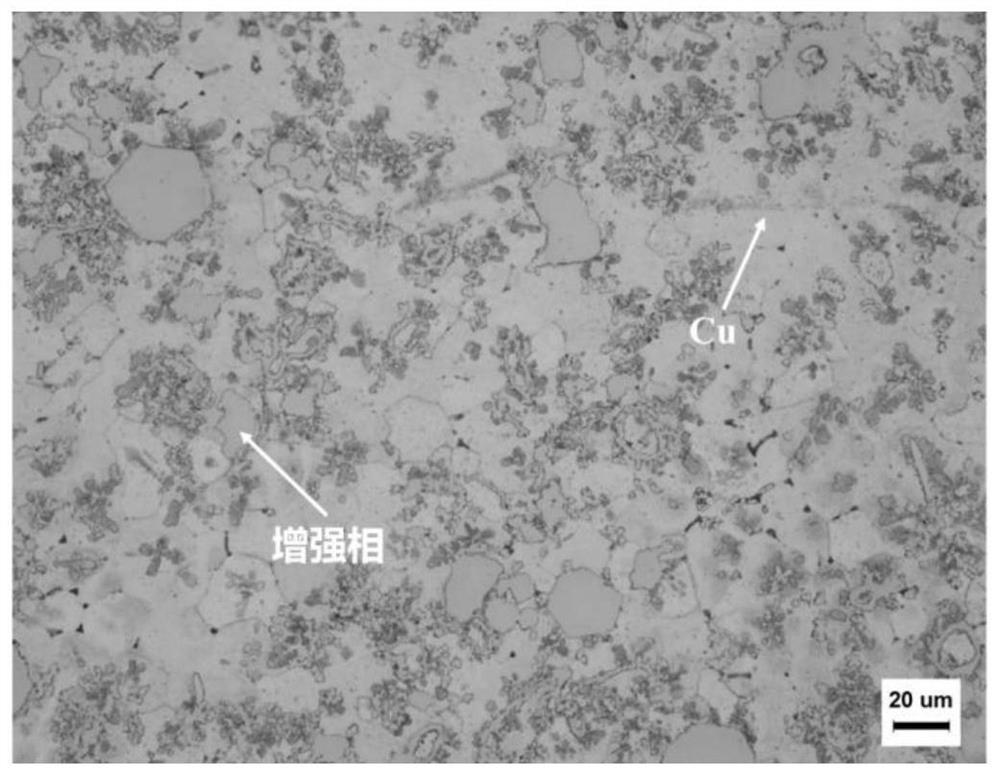

[0046] Step 1: Preparation of flux-cored welding wire for the working layer: Weigh the powder according to mass percentage: C powder 2.5%-6.1%, Nb powder 19.3%, W powder 38.2%, Si powder 1%, Mn powder 1%, and the balance is Cu Powder, the sum of the mass percentages of the above components is 100%; the pure copper strip with a size of 7mm×0.2mm is cleaned with alcohol and placed on a wire drawing machine, and a U-shaped groove is pre-pressed with a mold, and the above powder is mixed evenly and filled in In the U-shaped groove of the copper strip, after closing and reducing the diameter, it is finally made into a flux-cored wire with a diameter of 1.6mm;

[0047] In step 1, by adjusting the C content, the carbide content generated in situ in the working layer can be cha...

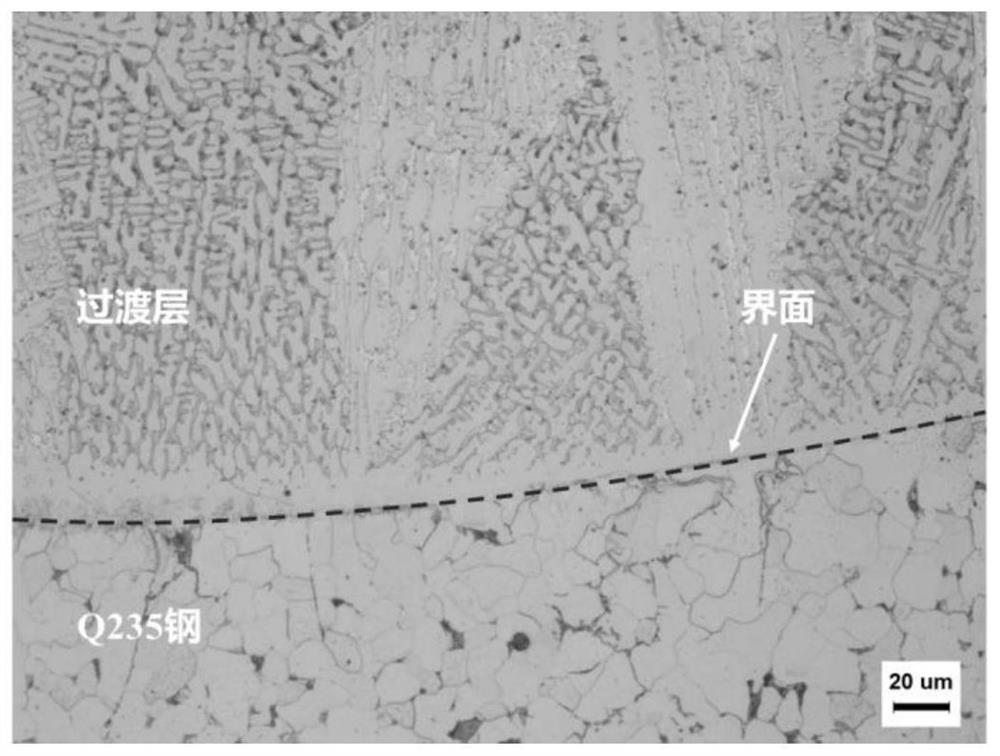

Embodiment 1

[0060] Step 1: Prepare flux-cored welding wire for the working layer: Weigh the powder according to mass percentage, C powder 2.5%, Nb powder 19.3%, W powder 38.2%, Si powder 1%, Mn powder 1%, and the balance is Cu powder, the above The sum of the mass percentages of the components is 100%; the pure copper strip with a size of 7mm×0.2mm is cleaned with alcohol and placed on the wire drawing machine, and the U-shaped groove is pre-pressed with a mold, and the above powder is mixed evenly and filled into the copper strip U In the groove, the filling rate is controlled at 35wt.% to 40wt.%. After closing and reducing the diameter, a flux-cored welding wire with a diameter of 1.6mm is finally produced.

[0061] Step 2: Prepare transition layer flux-cored welding wire: Weigh the powder according to mass percentage, Ni powder 35%, Nb powder 5%, W powder 5%, Si powder 1%, Mn powder 1%, and the balance is Cu powder, the above The sum of the mass percentages of the components is 100%; t...

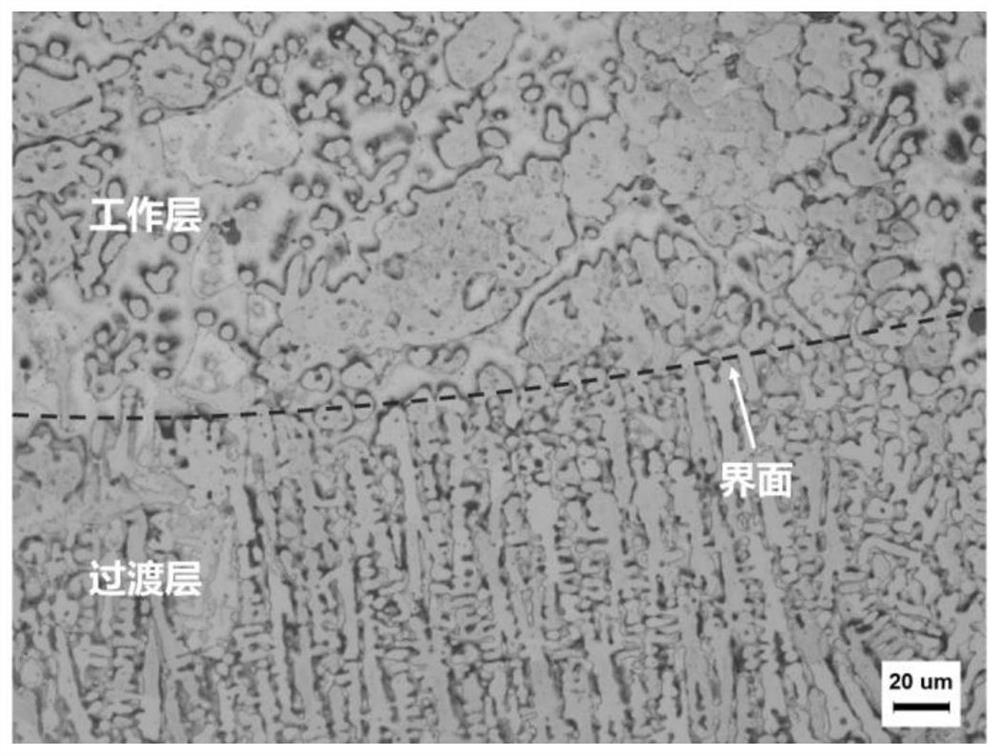

Embodiment 2

[0067] Step 1: Prepare flux-cored welding wire for the working layer: weigh the powder according to mass percentage, C powder 3.7%, Nb powder 19.3%, W powder 38.2%, Si powder 1%, Mn powder 1%, and the balance is Cu powder, the above The sum of the mass percentages of the components is 100%; the pure copper strip with a size of 7mm×0.2mm is cleaned with alcohol and placed on the wire drawing machine, and the U-shaped groove is pre-pressed with a mold, and the above powder is mixed evenly and filled into the copper strip U In the groove, the filling rate is controlled at 35wt.% to 40wt.%. After closing and reducing the diameter, a flux-cored welding wire with a diameter of 1.6mm is finally produced.

[0068] Step 2: Prepare transition layer flux-cored welding wire: Weigh the powder according to mass percentage, Ni powder 35%, Nb powder 5%, W powder 5%, Si powder 1%, Mn powder 1%, and the balance is Cu powder, the above The sum of the mass percentages of the components is 100%; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com