Material feeding type plastering device

A technology of plastering and feeding, which is applied in the direction of construction and building construction, can solve the problems of labor-intensive operation for workers, and achieve the effect of simple structure, convenient use and easy operation

Inactive Publication Date: 2008-10-22

ZHENGTAI GRP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention mainly aims at the shortcomings of the prior art manual plastering tools that frequently replenish mortar and the labor intensity of the workers, and proposes a feeding type plasterer with simple structure, easy operation, high construction efficiency, and sustainable supply of mortar

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

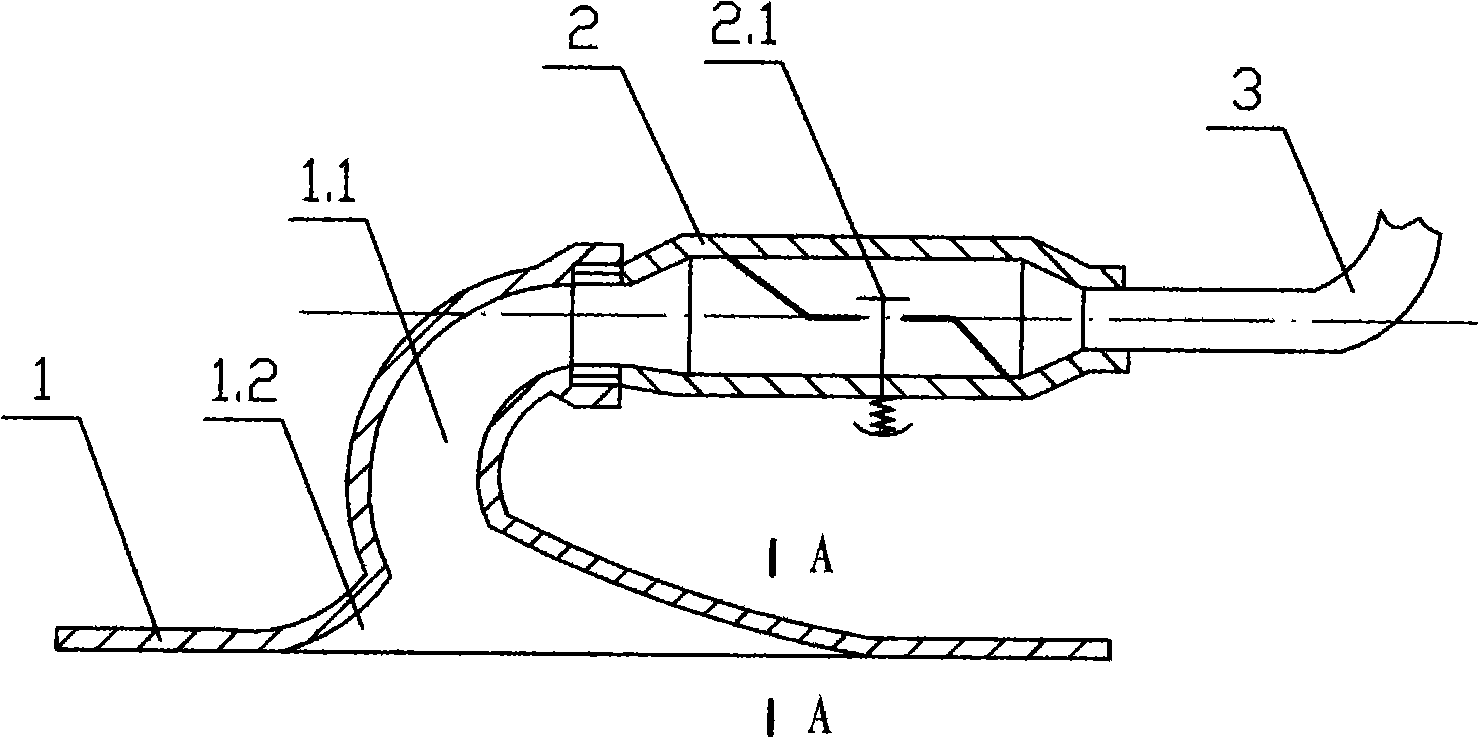

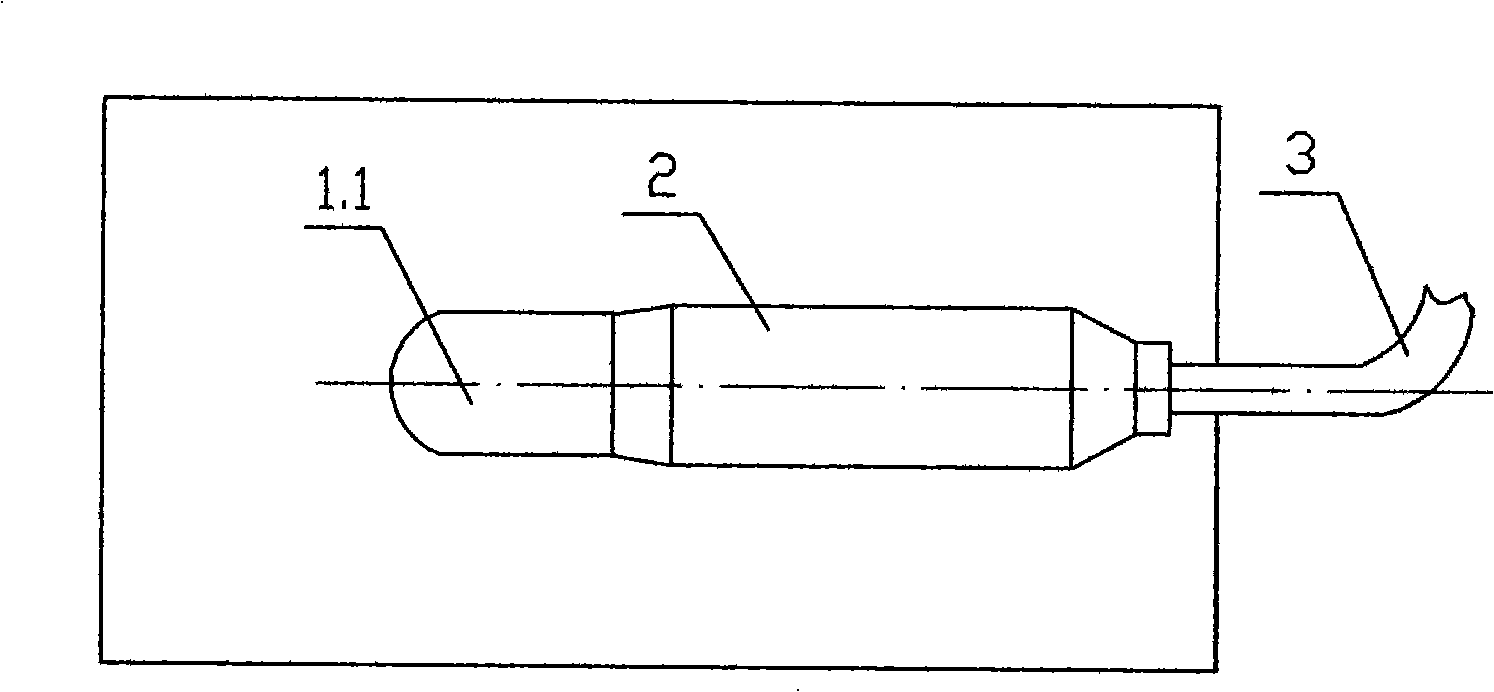

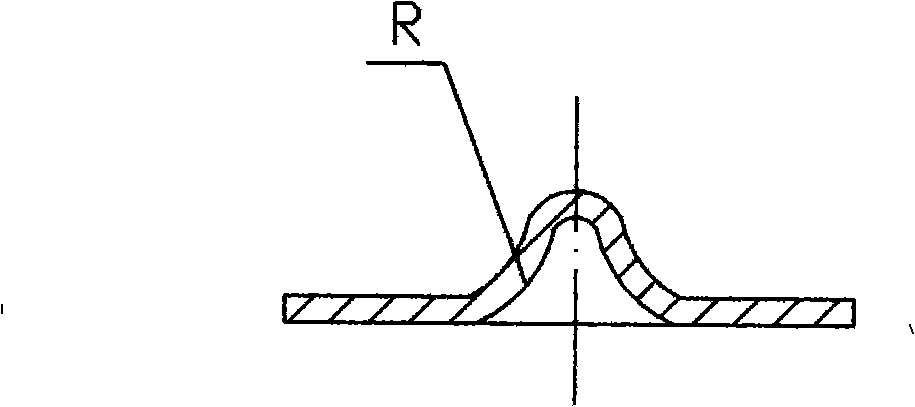

The invention discloses a fed type plasterer, belonging to construction tools. The plasterer comprises a flat, a flow valve and a feeding hose, wherein, the flat is a rectangular component with a thin wall; the bottom surface of the flat is a smooth plane; the middle of the flat is concave upward in the length direction to form a material cavity; the top of the material cavity bends and gradually shrinks into a hollow throat; one end of the flow valve is connected with the hollow throat while the other end is connected with the feeding hose; and the outer wall of the flow valve is provided with a hand switch with a normal close structure. When the plasterer is used, the outer wall of the flow valve is held by hands; the feeding hose is connected and introduced mortar, the bottom surface of the flat faces toward a construction surface, the hand switch is pressed to control the feeding amount of the mortar, the plasterer make rubbing and leveling operations during moving process. The plasterer has the advantages of continuous feeding, nonproductive time conservation, high construction efficiency and low labor intensity, is particularly suitable for extensive constructions.

Description

Feeding Plasterer technical field The invention relates to a building construction tool, in particular to a manual plastering tool. Background technique Plastering is a relatively important process in building construction, and its construction quality directly affects the quality of the building surface. The existing plastering tool is a traditional mud scraper, and the worker uses the mud scraper to take a small amount of mortar and aim at the construction site to apply pressure and knead while smoothing. Although the manual plastering tool in the prior art is simple in structure and cheap, it can realize the troweling operation on the construction site. However, the plastering tools in the prior art require sporadic mortars to be constructed and smoothed separately, which has high labor intensity and low construction efficiency, and cannot meet the efficient construction requirements of construction projects. Contents of the invention The present invention mainly a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04F21/08E04F21/16

Inventor 宋增贤孟向惠

Owner ZHENGTAI GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com