High-temperature condensation water recovery device

A technology of high-temperature condensation and water recovery, which is applied in the direction of supplementary feed water, feed water heater, preheating, etc., and can solve problems such as insufficient boiler inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

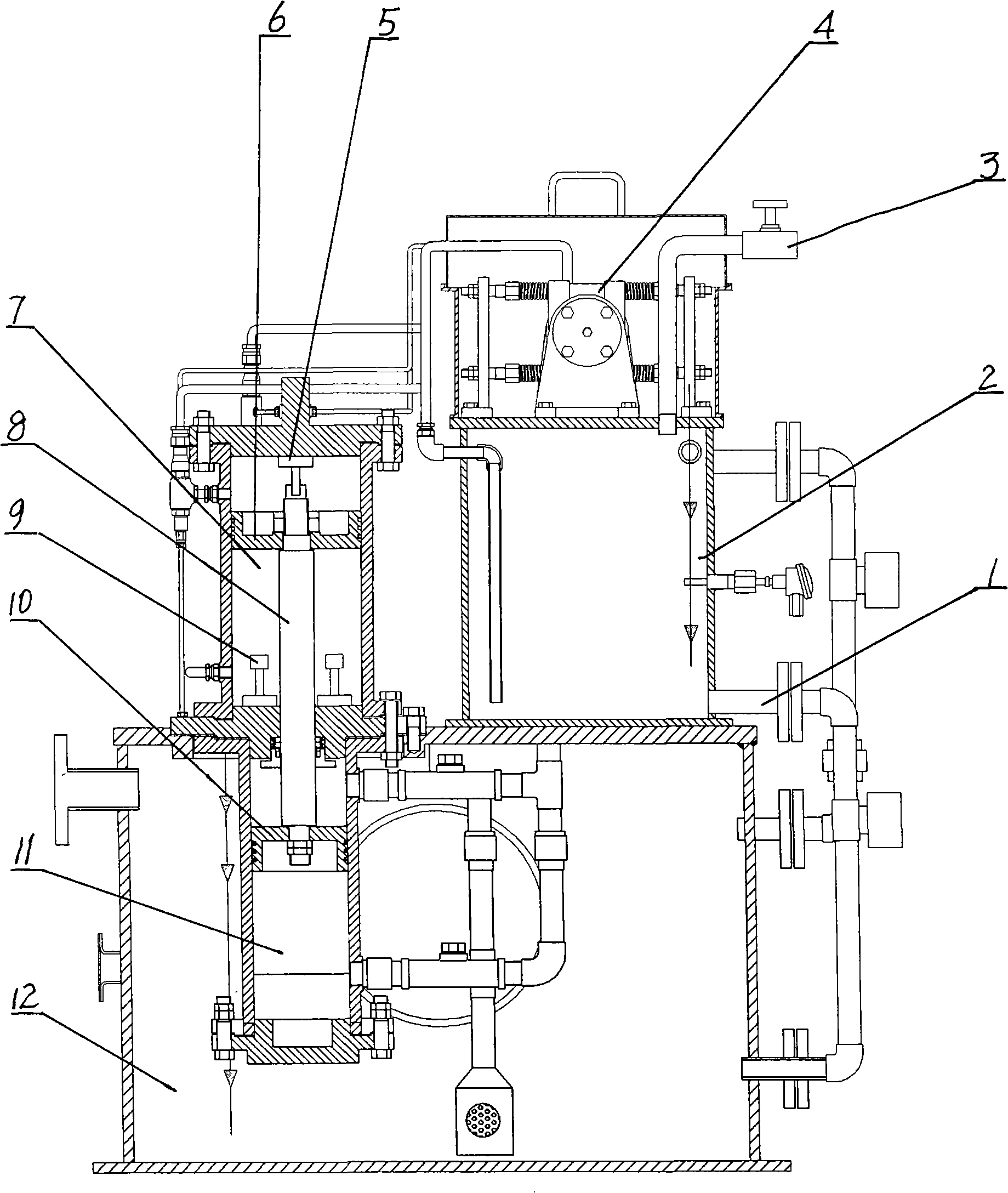

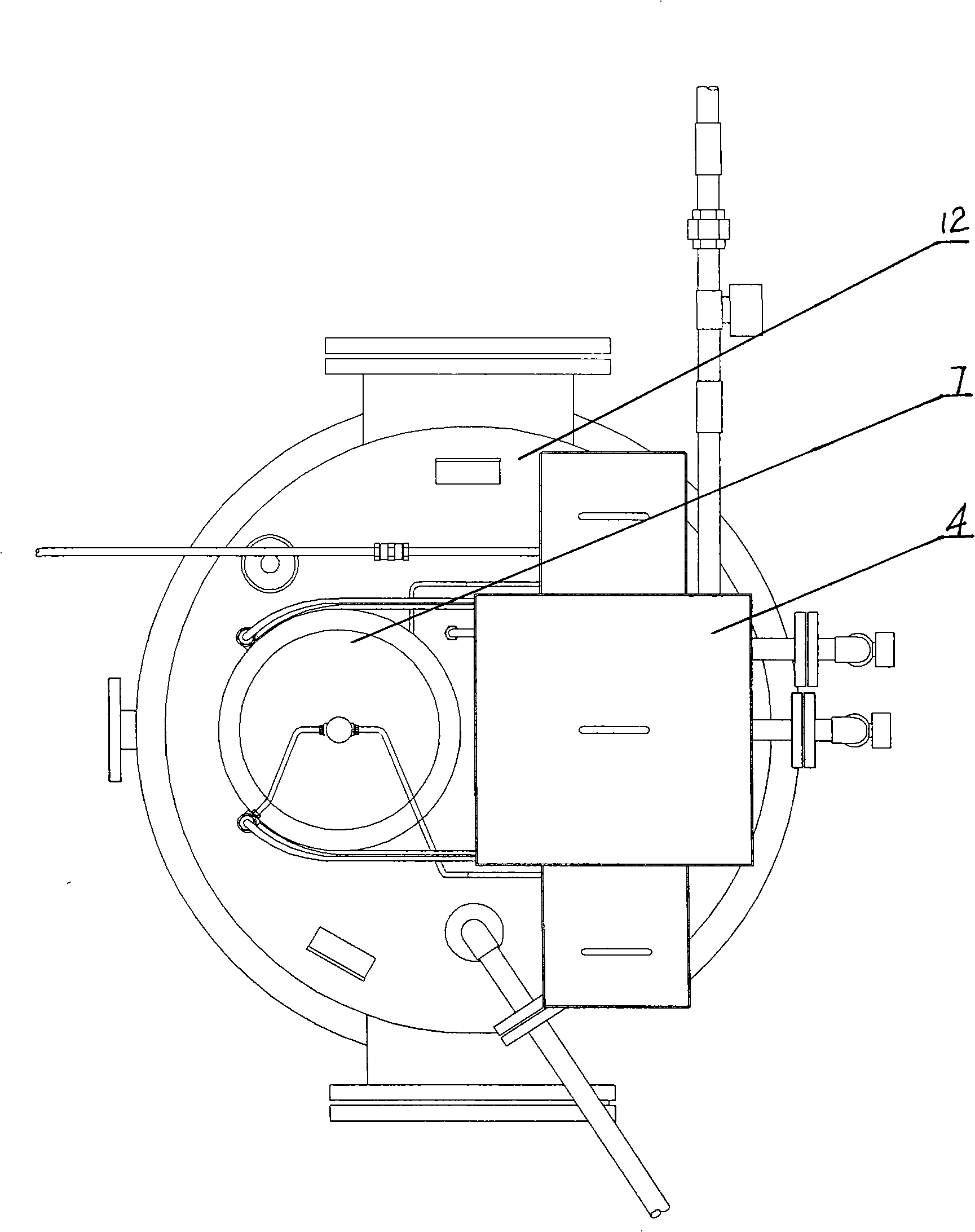

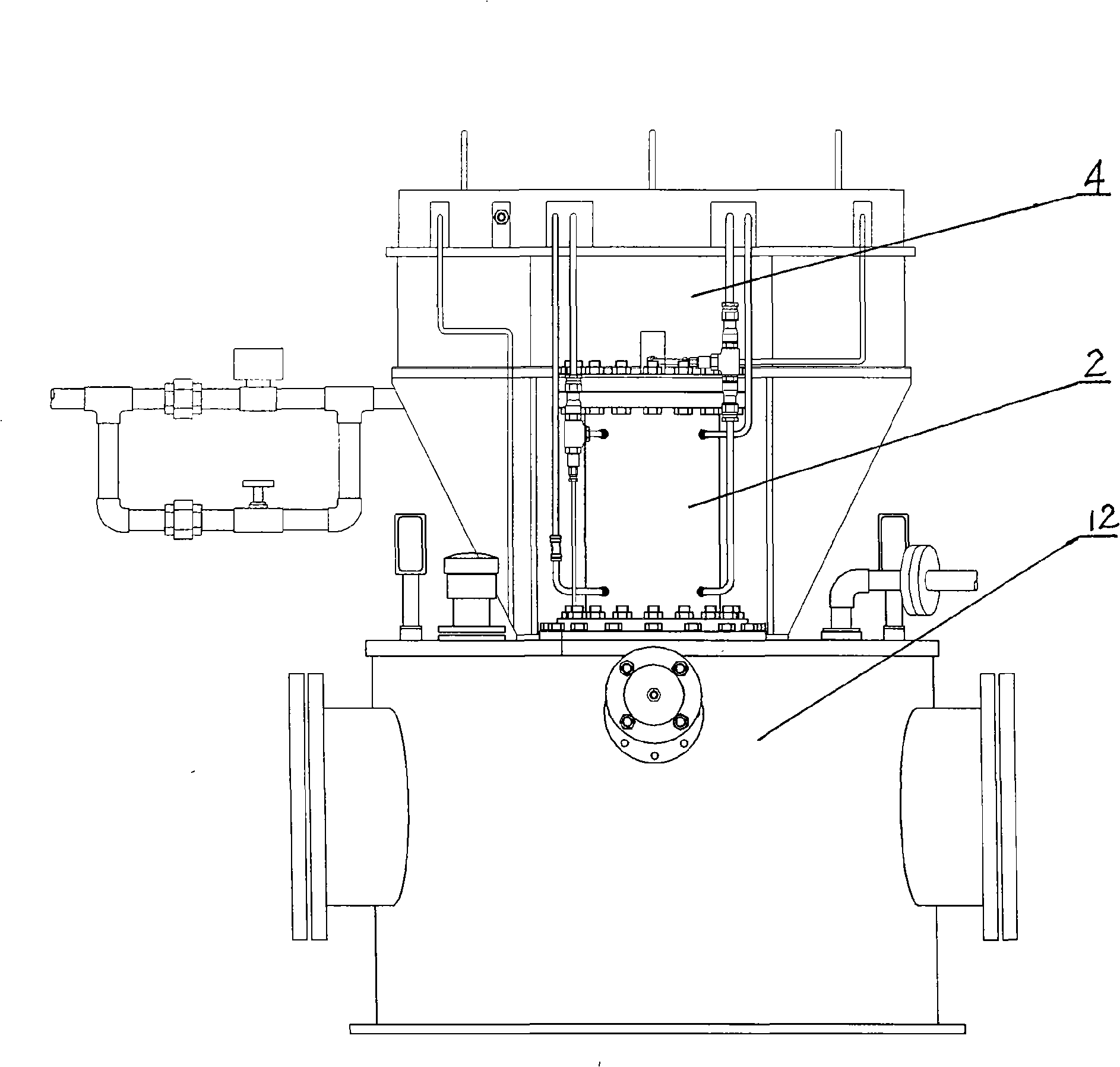

[0043] The present invention includes a condensed water tank 12, the condensed water tank 12 is connected with the upper replenishing water tank 2 through the pipeline 1, the steam power cylinder 7 is above the condensed water recovery cylinder 11 in the condensed water tank 12, and the condensed water recovery cylinder 11 is shared with the steam power cylinder 7 The piston rod 8 and the diameter of the piston 10 of the condensed water recovery cylinder 11 are smaller than the diameter of the piston 6 of the steam power cylinder 7 .

[0044] The top and bottom of the cylinder body of the steam power cylinder 7 are respectively provided with a top valve 5 and a bottom valve 9. The valve 4 is connected; the reversing rod 18 between the reversing cylinder 19 and the reversing valve 4 is provided with a fixed block 17 and a sliding reversing block 14, and the reversing rod 18 between the fixed block 17 and the sliding reversing block 14 A return spring 16 is provided, and pre-tig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap