Highly effective natural energy heat pump

A natural energy and high-efficiency technology, applied in the field of heat pump systems and high-efficiency natural energy heat pumps, can solve the problems of low refrigerant evaporation and heat absorption capacity, high return air and exhaust pressure, and slow heating speed, etc., to achieve long service life, Stable working performance, efficient and rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

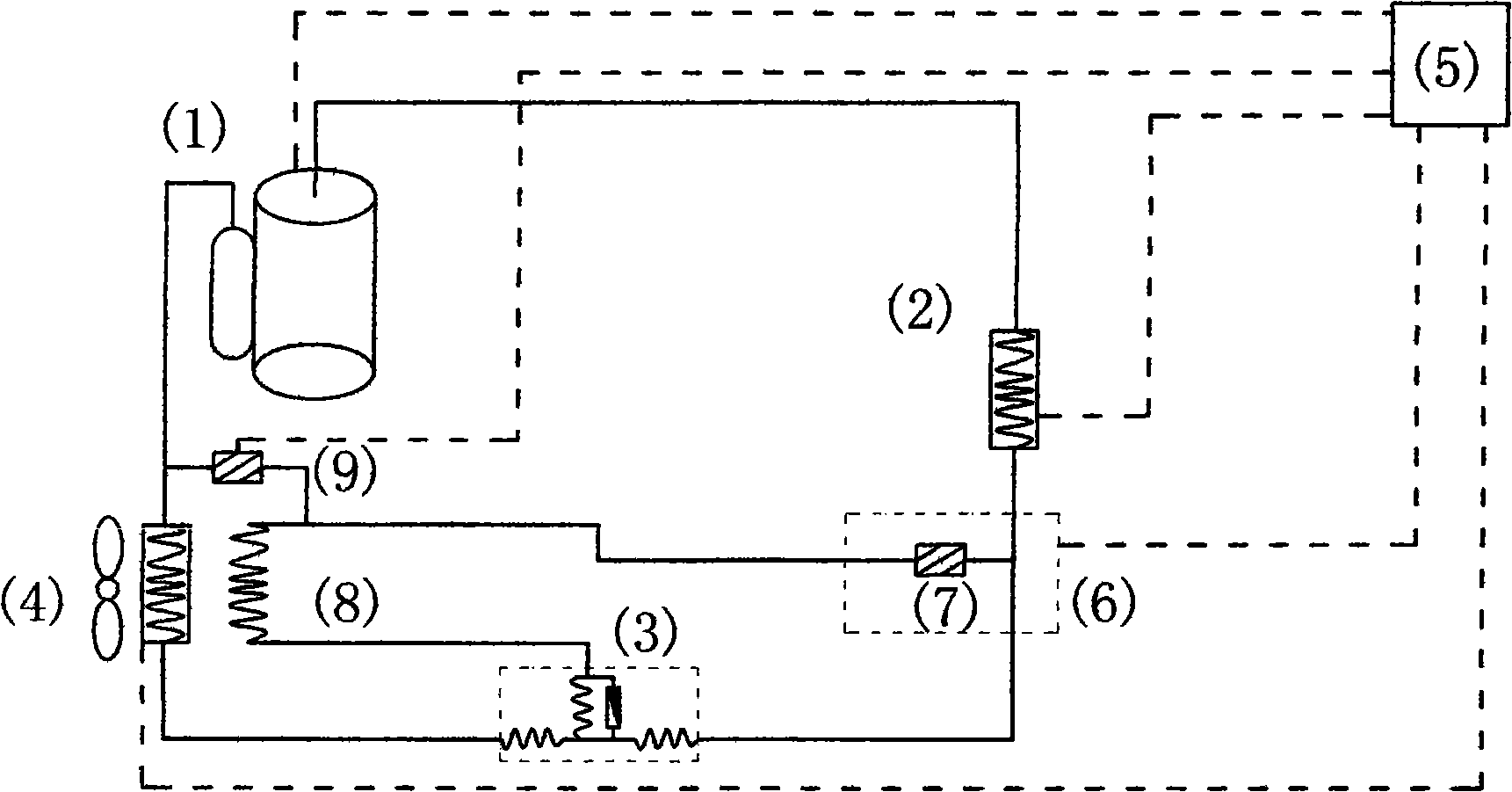

Embodiment 1

[0016] Embodiment 1: A high-efficiency natural energy heat pump mainly consists of a compressor (1), an indoor heat exchanger (2), a throttling device (3), and an outdoor heat exchanger (4), and is composed of an appropriate amount of copper pipes, etc. The accessories are connected in sequence to form a refrigerant closed cycle passage system, and the system is controlled by the electric control device (5). The diverter device (6) is divided into two paths, one of which is connected to the throttling device (3) through corresponding copper pipes and other fittings, and the other path is connected with a natural The inlet of the natural energy heat exchanger (8) is connected, the outlet of the natural energy heat exchanger (8) is connected with the throttling device (3) through corresponding copper pipes and other fittings, and the inlet of a return air valve (9) is also connected with the The refrigerant inlet of the natural energy heat exchanger (8) is connected, and the out...

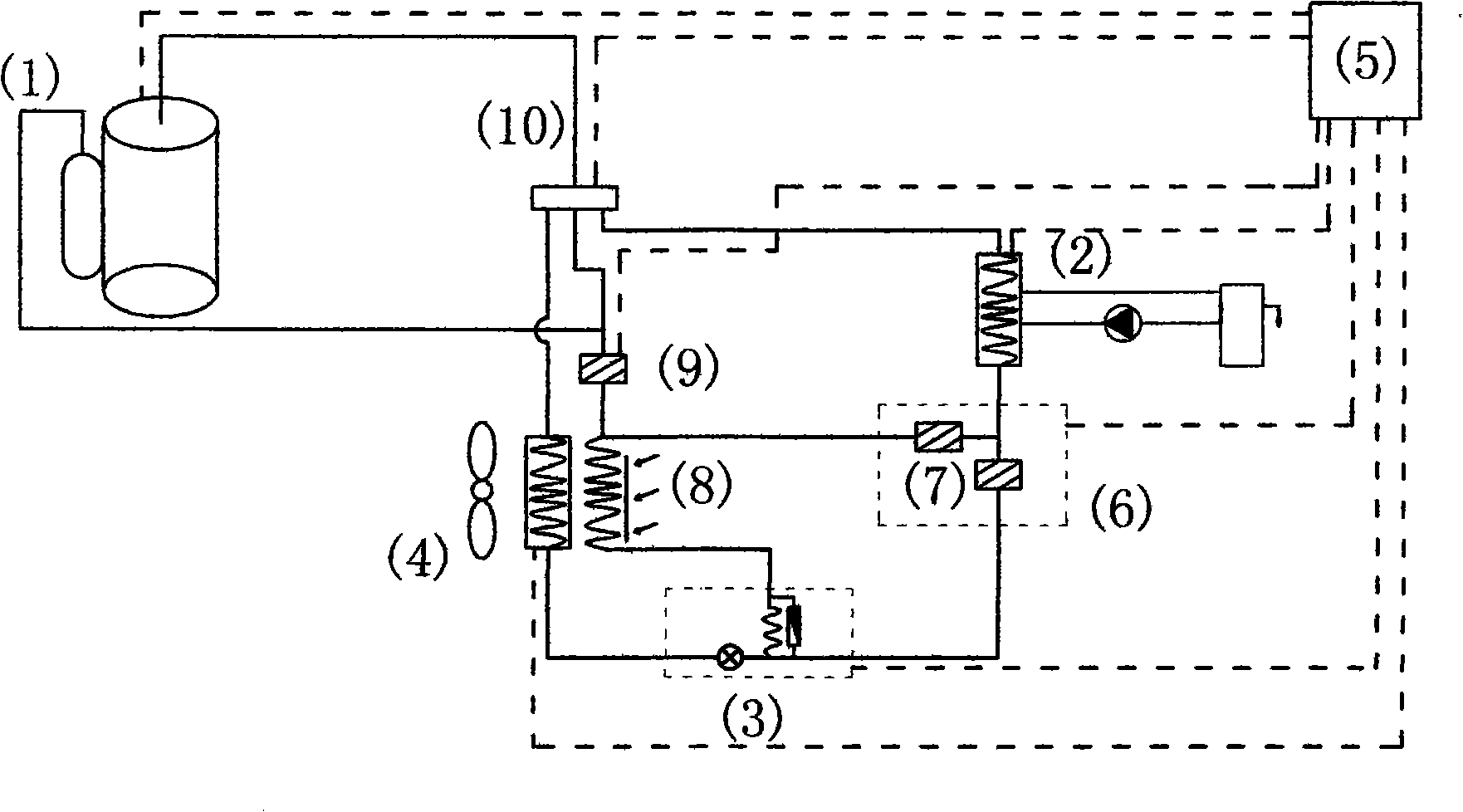

Embodiment 2

[0019] Embodiment 2: A high-efficiency natural energy heat pump mainly includes a compressor (1), a four-way reversing valve (10), an indoor heat exchanger (2), a throttling device (3), and an outdoor heat exchanger (4) It is composed of a proper amount of copper pipes and other fittings to form a refrigerant closed cycle passage system. This system is controlled by an electric control device (5). In particular, in the above system, the refrigerant outlet of the indoor heat exchanger (2) passes through A diversion device (6) equipped with a control valve (7) is divided into two circuits, one of which is connected in series with a control valve (7) and connected with the throttling device (3) through corresponding copper pipes and other fittings. The other path of another control valve (7) is connected to the inlet of a natural energy heat exchanger (8) through corresponding fittings such as copper pipes, and the outlet of the natural energy heat exchanger (8) is connected to th...

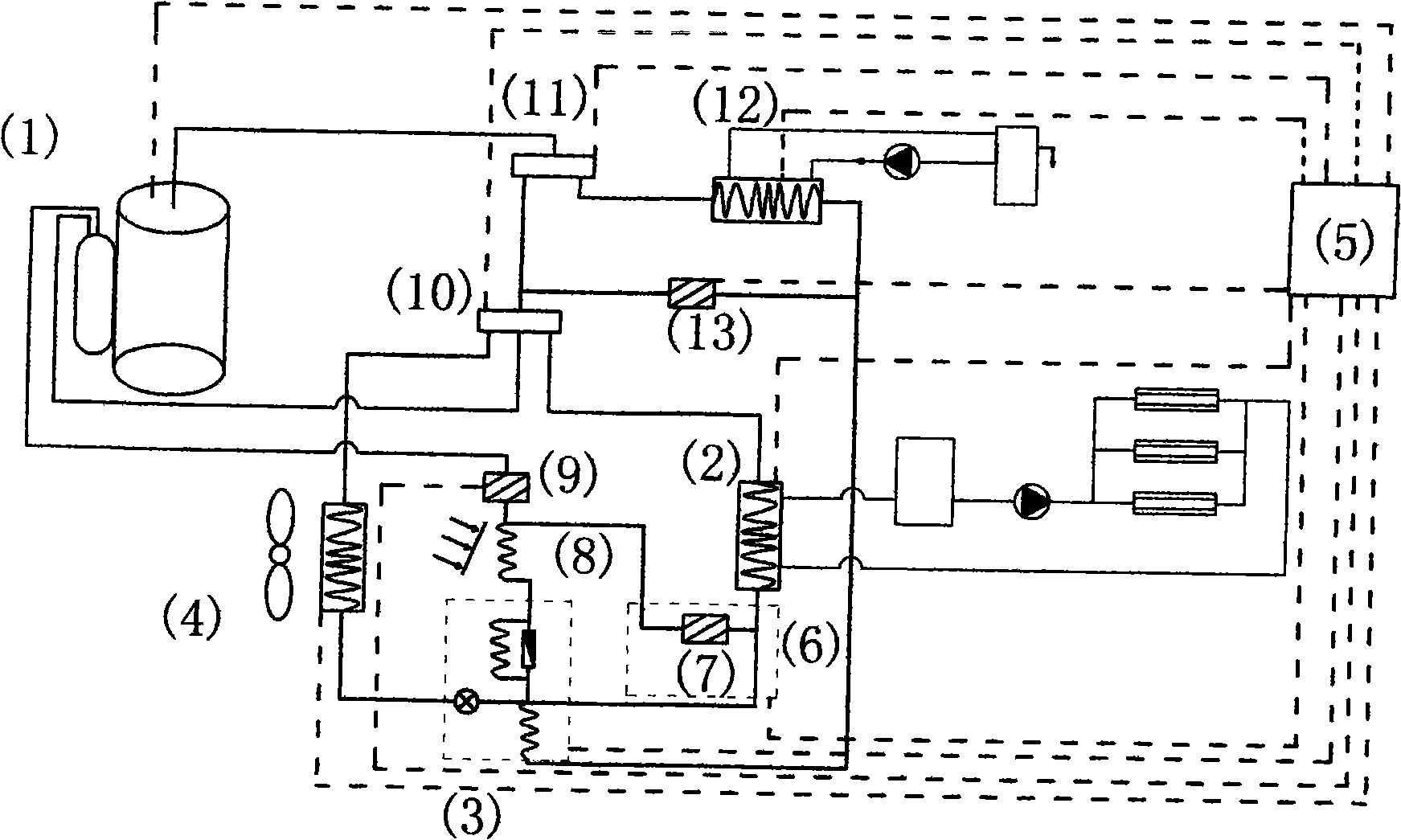

Embodiment 3

[0022] Embodiment 3: A high-efficiency natural energy heat pump mainly includes a compressor (1), a gating valve (11), a water condenser (12), a gating device (13), a four-way reversing valve (10), an indoor The heat exchanger (2), the throttling device (3), and the outdoor heat exchanger (4) are connected in turn by a proper amount of copper pipes and other accessories to form a refrigerant closed circulation path system. The system consists of an electric control device (5 ) control work, in particular, the refrigerant outlet of the indoor heat exchanger (2) in the above system is divided into two paths through a diverter device (6) with a control valve (7), one of which passes through corresponding copper pipes and other fittings and joints. flow device (3), connected in series with a control valve (7), the other channel is connected to the inlet of a natural energy heat exchanger (8) through corresponding copper pipes and other fittings, and the outlet of the natural energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com