Liquid dynamic surface fermentation tower

A fermentation tower and dynamic technology, which is applied in the field of microbial liquid fermentation devices, can solve the problems of equipment versatility, poor flexibility in flexible operation, huge system of main equipment and auxiliary equipment, and low degree of spatial adjustment of production capacity fluctuations. Speed and conversion rate of raw materials, elimination of air purification equipment and stirring equipment, and the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

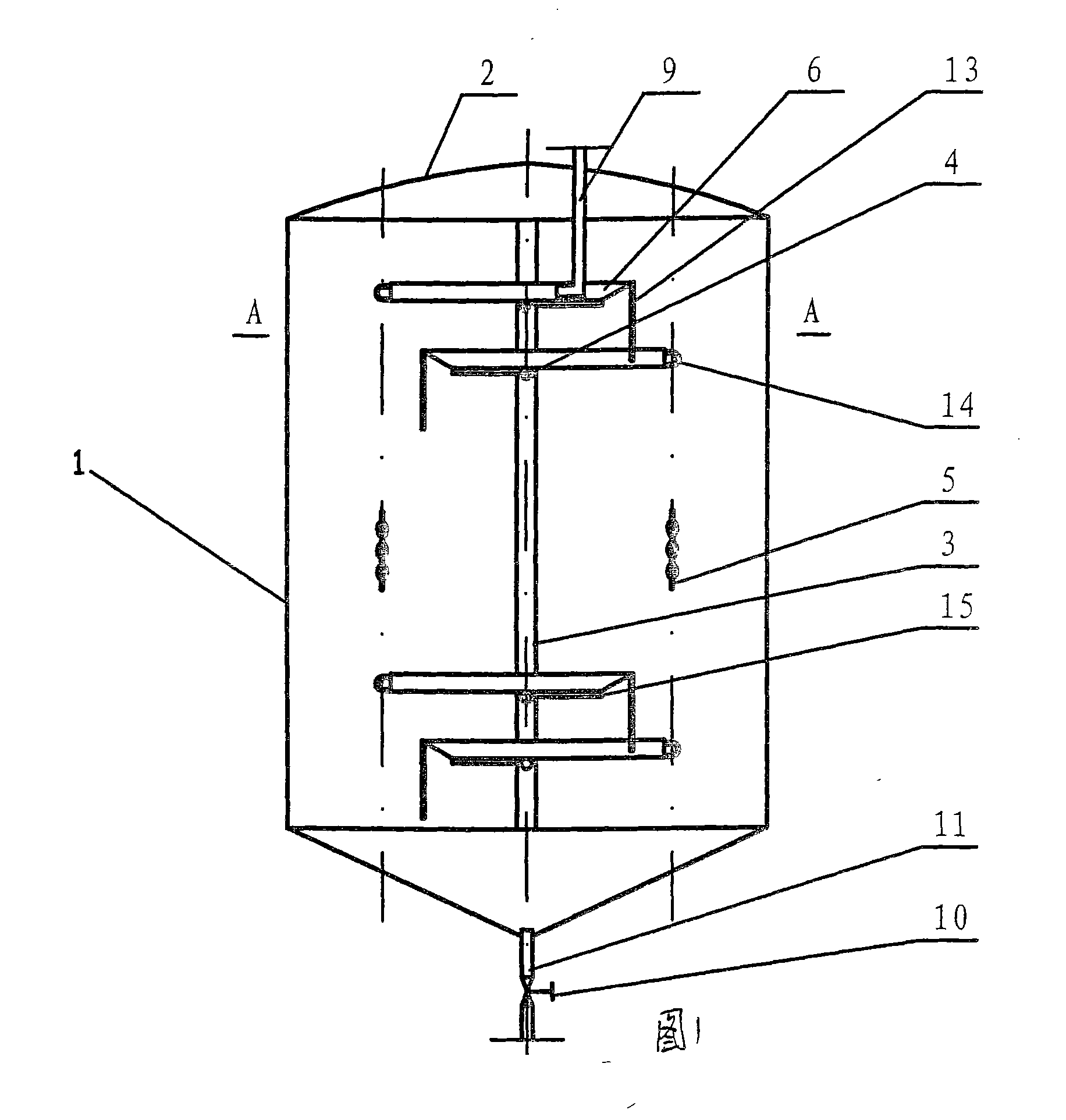

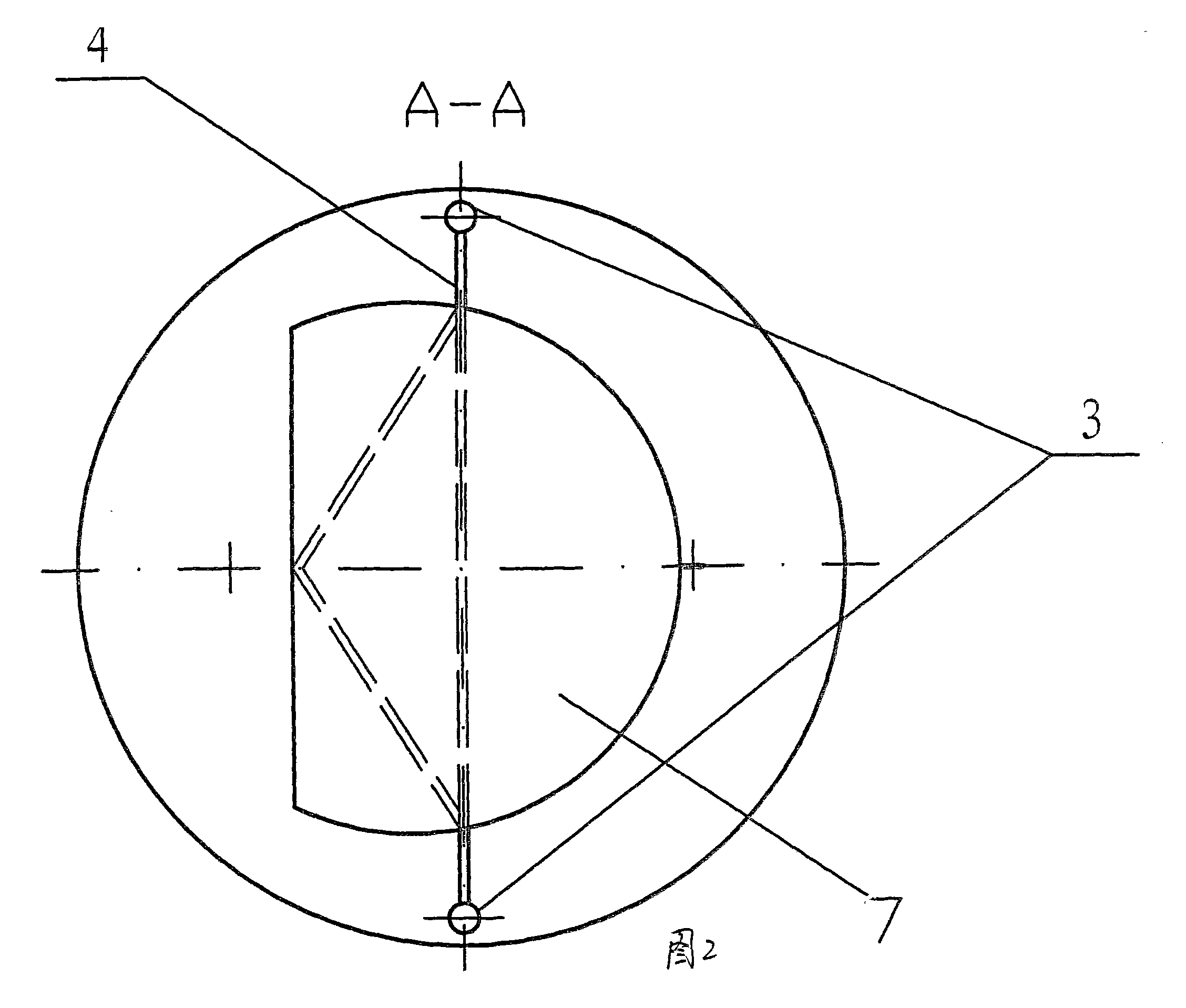

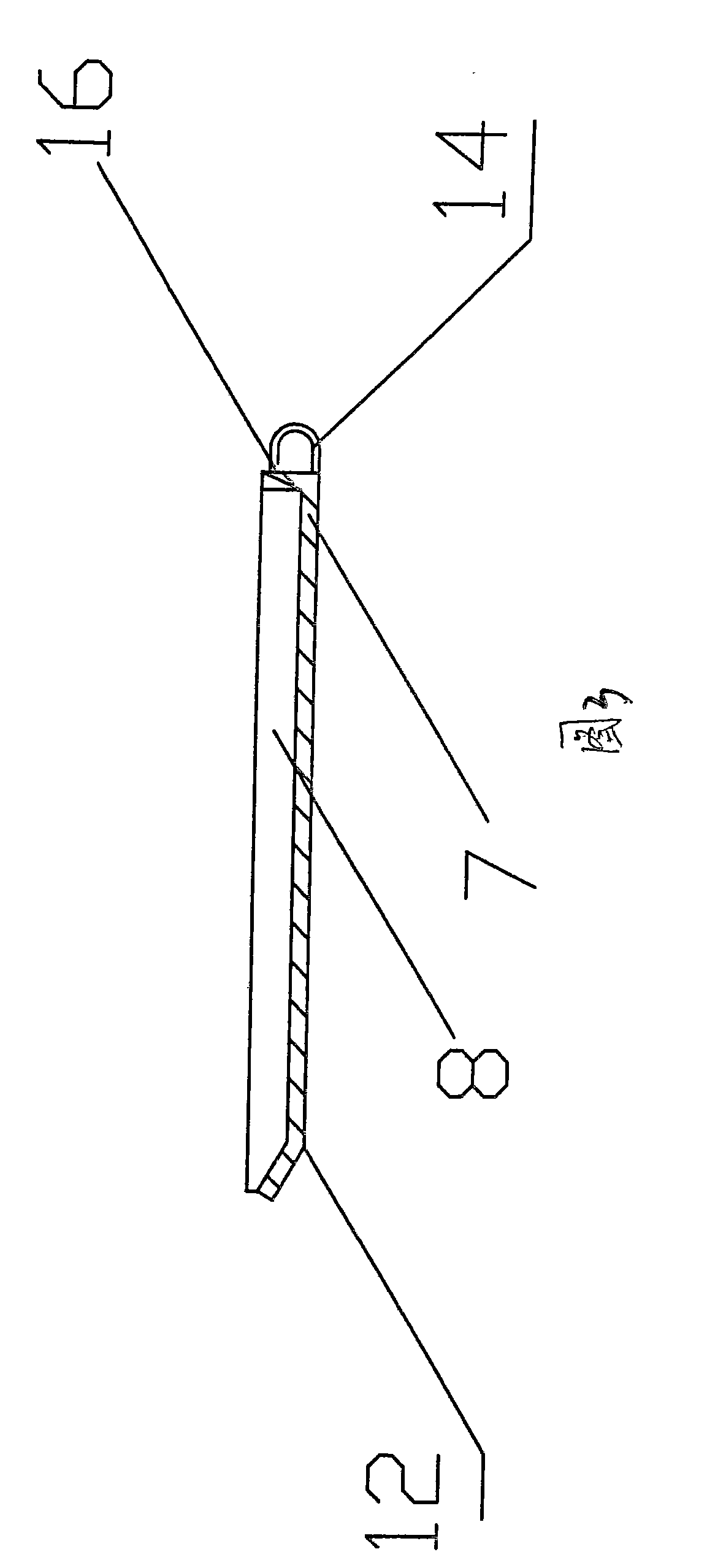

[0022] As shown in Figure 1-3, the fermentation tower includes a tower body 1, a top cover 2, a support column 3, a carrier frame 4, a lifting chain 5 and a circular liquid-receiving tray 6, and the top cover 2 is installed on the tower body 1 to form a circle. Cylindrical fermentation tower, two vertical support columns 3 are installed at both ends of the fermentation tower in the diameter direction, two lifting chains 5 are installed in the fermentation tower and the support columns 3 are arranged in a cross shape, and a group of rotating shafts 4 are layered horizontally It is movably installed on the supporting column 3, and the circular segment liquid receiving plate 6 is installed on the rotating shaft 4, and the arc apex of the circular segment liquid receiving plate 6 is connected with the lifting chain 5 by the chain ring 14, and the circle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com