Construction method for embedding thermal insulation in concrete structure exterior wall surface

A technology of concrete structure and construction method, applied in the direction of thermal insulation, wall, building components, etc., can solve the problems of not achieving good thermal insulation effect, cracking on the outer surface of the building, affecting the appearance, etc. Degree, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

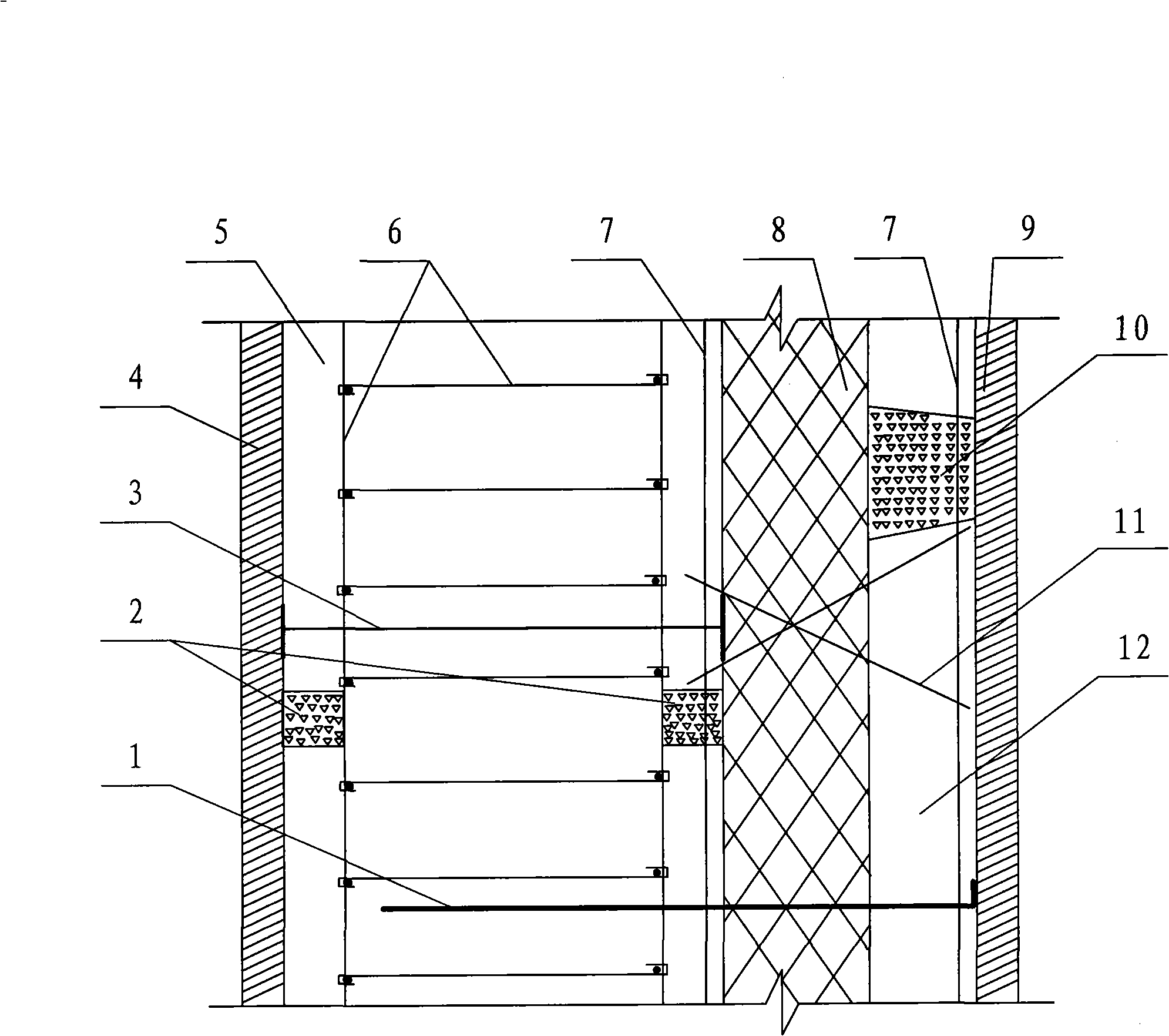

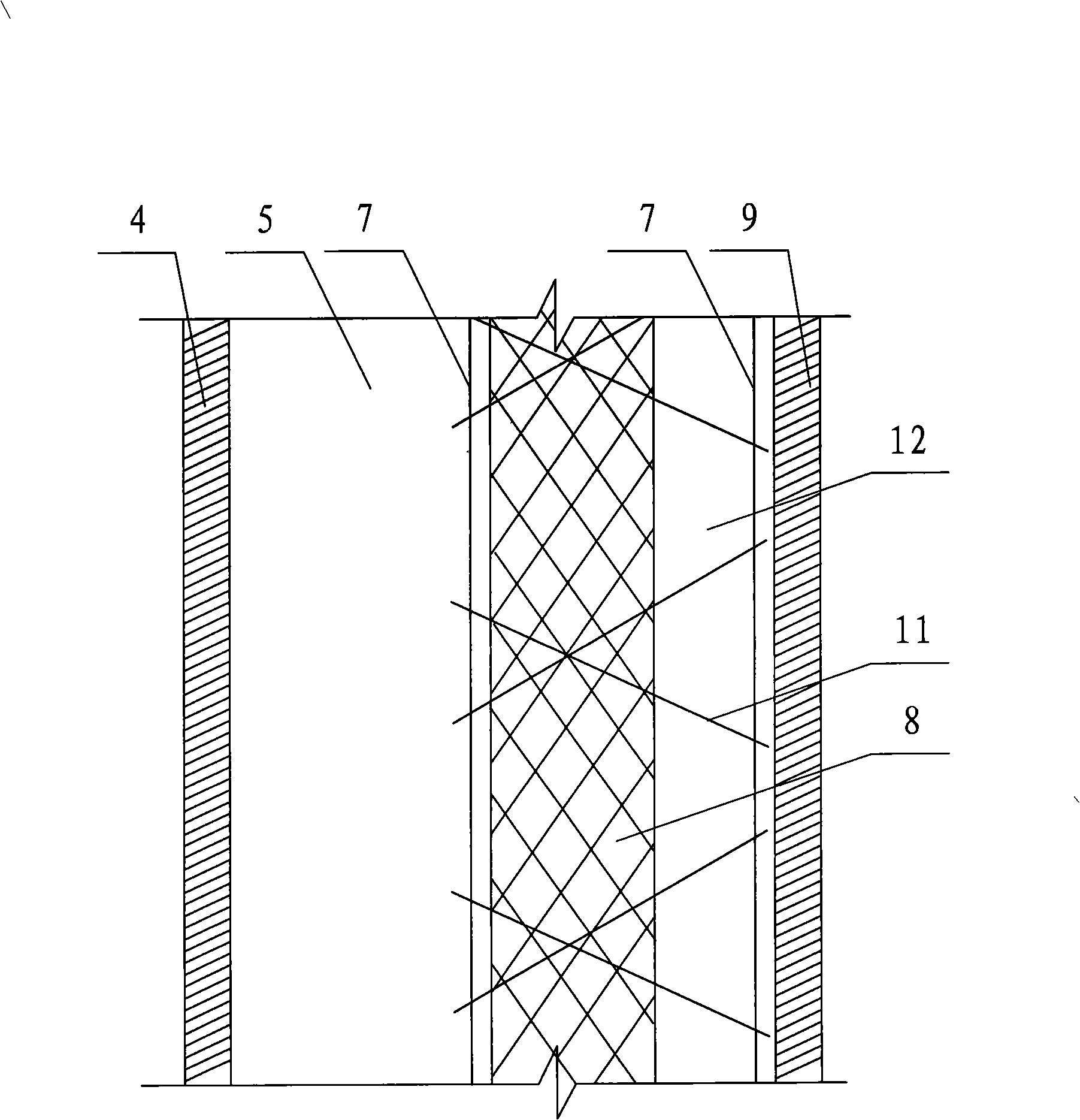

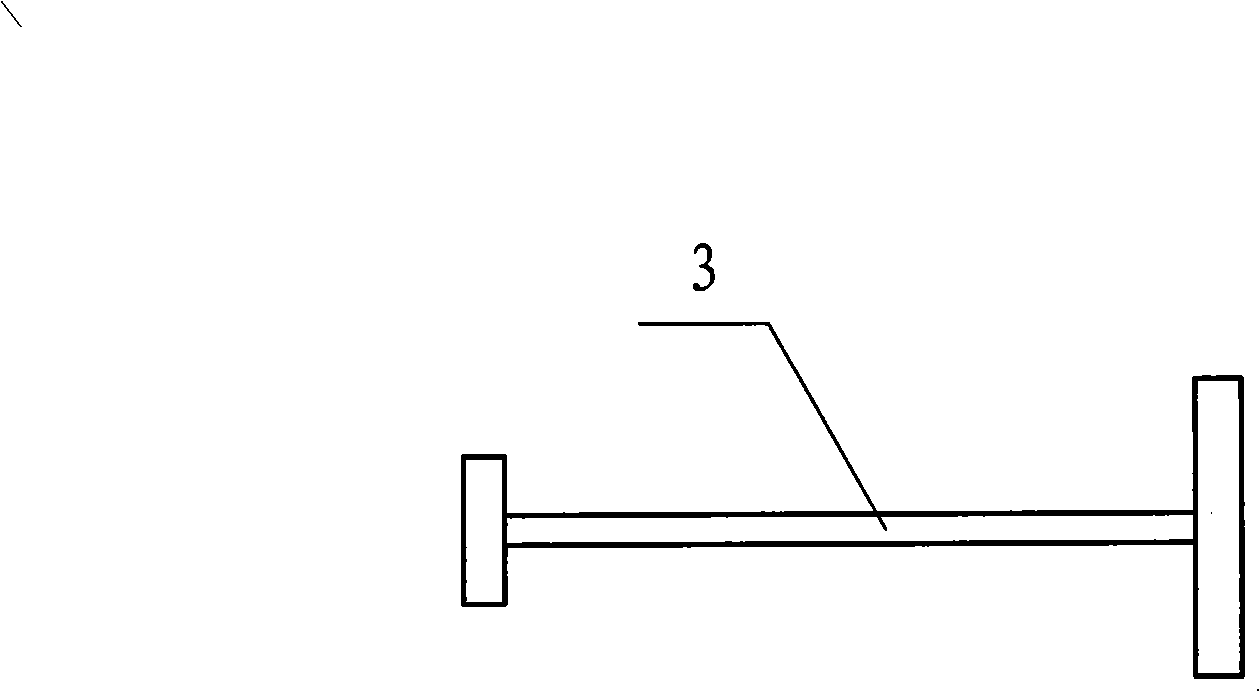

[0034] Example: see Figure 1-Figure 5 , in the figure, 1-auxiliary fixing rod, 2-concrete pad, 3-steel frame, 4-inner formwork, 5-wall, 6-wall structure reinforcement, 7-reinforcing mesh, 8-polystyrene board, 9-outer formwork, 10-concrete cushion block, 11-steel bar (belly wire), 12-self-tight high-performance concrete body.

[0035] In the present invention, the built-in thermal insulation layer of the concrete structure is a structure in which two layers of steel mesh 7 are sandwiched between polystyrene boards 8 and then three-dimensional obliquely inserted steel bars 11 are welded into thermal insulation grid panels, and concrete is poured on both sides at the same time. The polystyrene board 8 is an extruded polystyrene board.

[0036] The construction method of the built-in insulation layer on the outer wall of the concrete structure includes the following steps:

[0037] a. Fabrication of the thermal insulation grid plate: the polystyrene board 8 is placed between tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com