Mine rock material profile modeling recovery method and special equipment thereof

A technology of mining method and special equipment, which is applied in open-pit mining, stone processing equipment, ground mining, etc., can solve the problems of inconvenient hoisting and transportation of large stones, inability to meet the needs of stone profiling, and occupation of worktables, etc. The effect of manual carving and chiseling process, reducing transportation weight and improving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

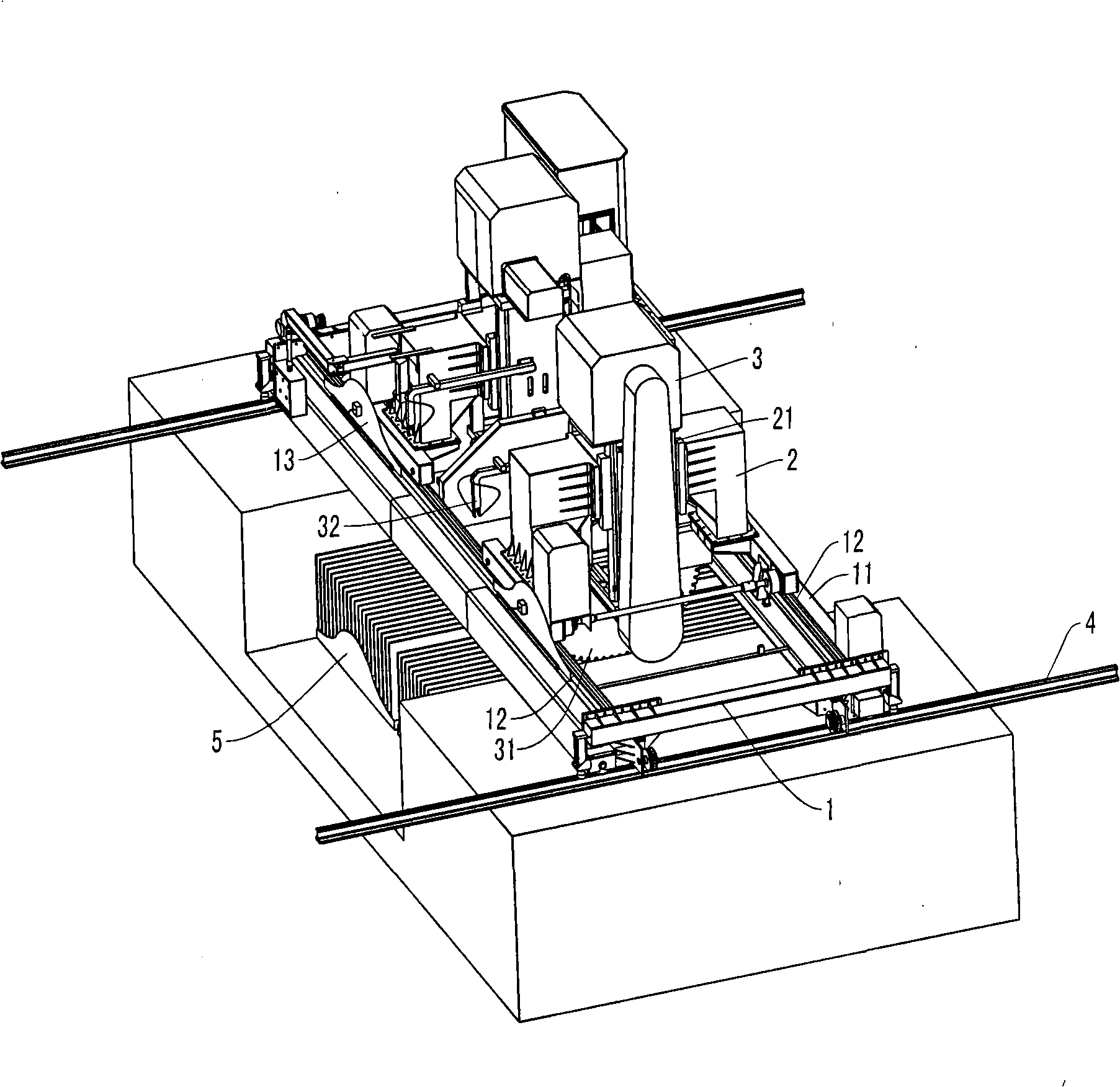

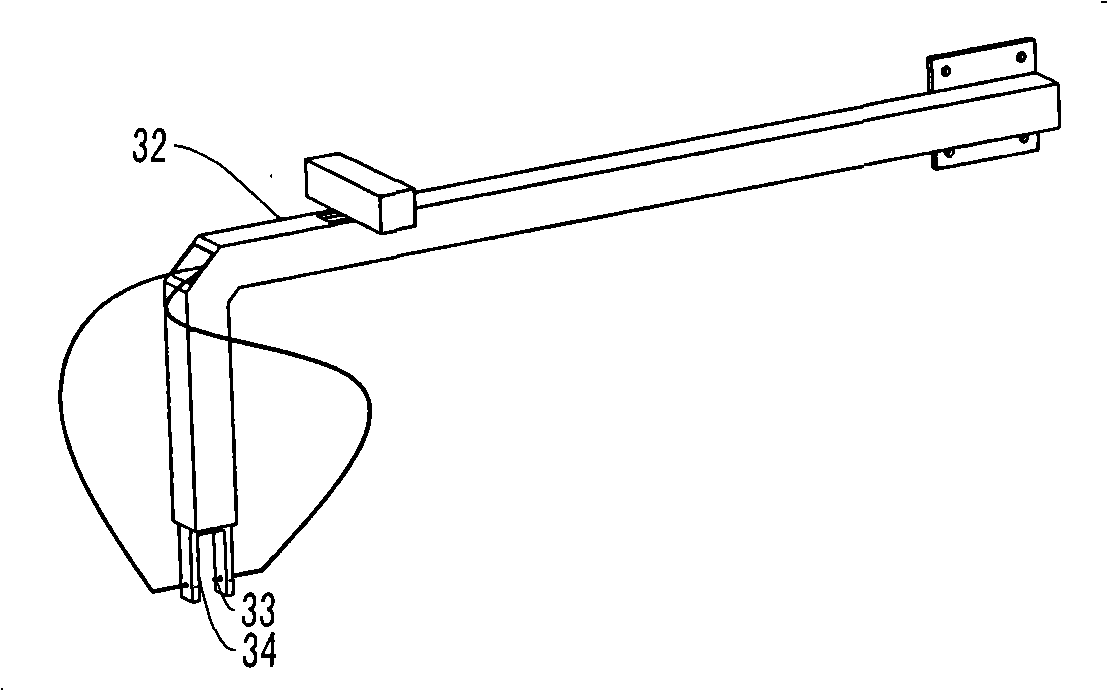

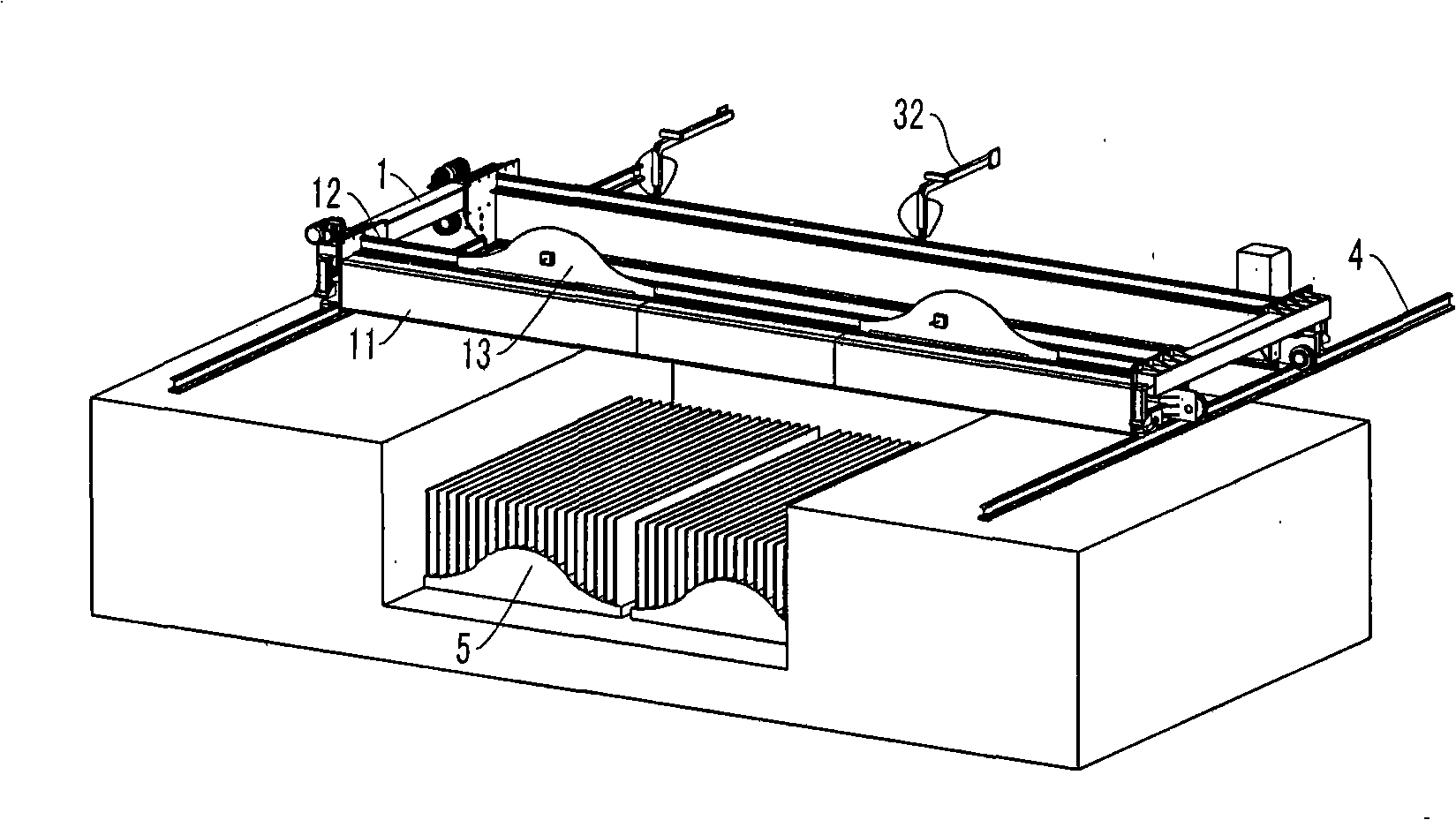

[0029] refer to figure 1 , figure 2 and image 3 , special equipment for mine stone profiling mining, including a walking frame 1 that can walk on the track 4 fixed on the surface of the mine. The walking frame 1 has a rectangular structure. The auxiliary track 12 is equipped with a support frame 2 on the auxiliary track 12. This support frame 2 can be a beam or two columns. The vertical rail 21 is arranged on the support frame 2, and the lifting saw machine 3 is installed on the vertical rail 21. The lifting saw machine 3 can move up and down under the drive of power, so that the saw blade 31 in the lifting saw machine can move up and down. , to complete the profiling cutting in different shades. The profiling cutting is completed by the cooperation of the following mechanisms. Its one-way profiling is composed of a horizontal cam 13 arranged in the parallel direction of the auxiliary rail 12 and a height sensing rod 32 fixed on the lifting saw machine 3. The lateral cam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com