Cleaning method and device for anode roasting fire path wall

The technology of a cleaning device and a cleaning method is applied in the field of cleaning the flue wall of an anode roasting furnace, which can solve problems such as a large amount of dust raised by the anode roasting furnace, unsatisfactory cleaning effect, and long shutdown time, etc., and achieves improvement. The effect of working environment and labor intensity, shortening the shutdown time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

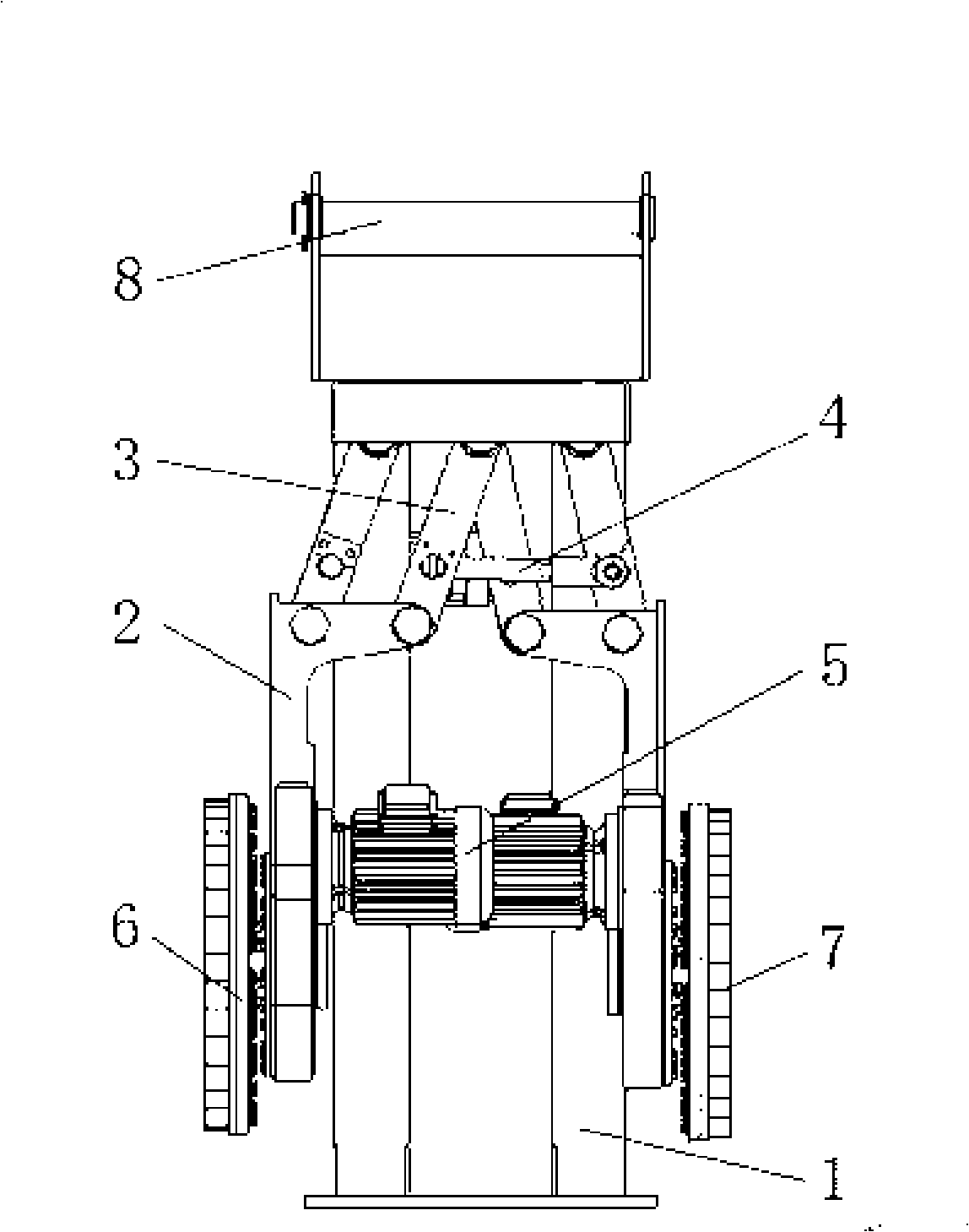

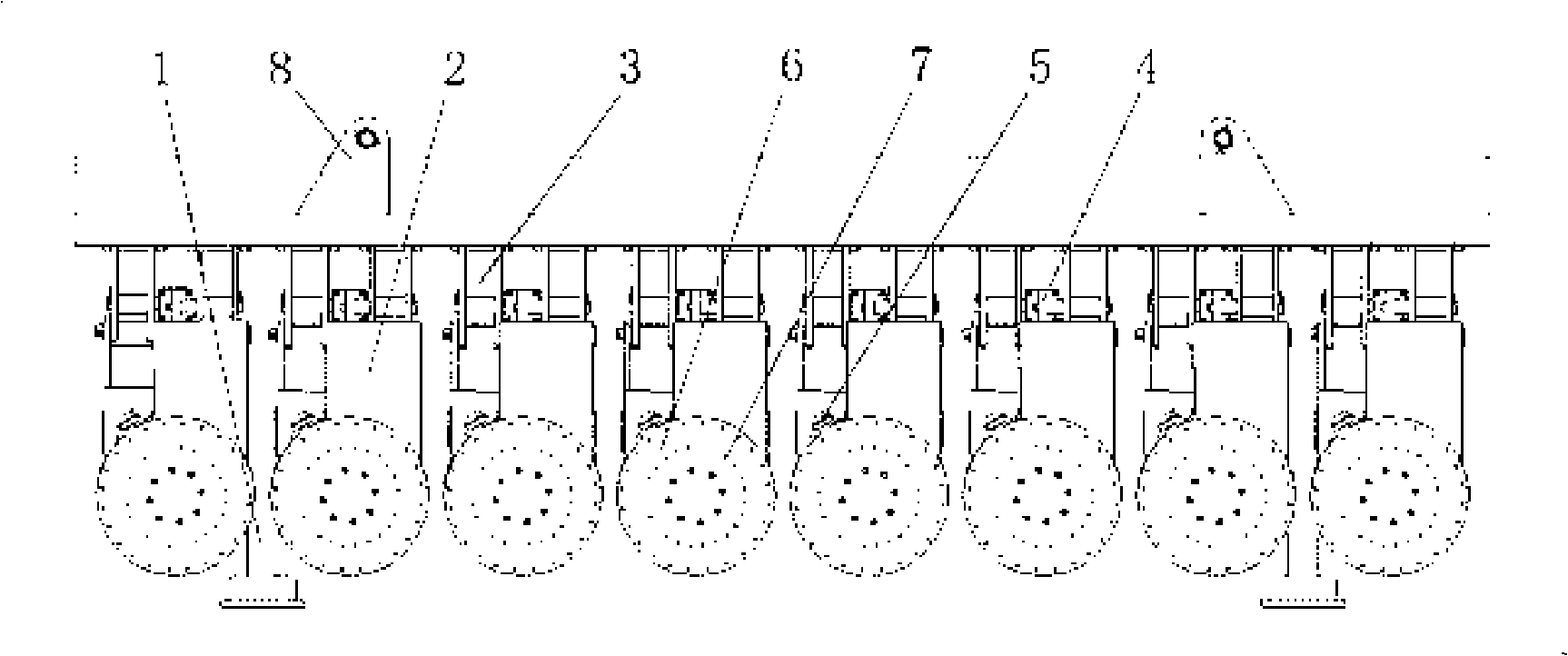

[0017] Examples of the present invention are figure 1 and figure 2 Shown: the method of the present invention is: replace the manual cleaning of prior art with mechanical cleaning, design and make a cleaning device specially for the flue wall of anode roasting furnace earlier, this device it comprises frame 1, in frame 1 A movable support 2 is respectively installed symmetrically on both sides, and the movable support 2 is hinged with the frame 1 through the connecting rod 3, so that the movable support 2 can be freely expanded and contracted by the frame 1 on both sides. The rod 3 adopts a double-link structure parallel to each other, and a telescopic element 4 is hinged between the corresponding connecting rods 3 on both sides of the frame 1; the so-called flexible element 4 can be a cylinder, a hydraulic cylinder, or a solenoid valve. Or spring, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com