Surface gas flow purging thermal desorption sampling device

A technology of airflow purging and sampling device, which is applied in the field of sampling device of ion mobility spectrometer, can solve the problems of not being suitable for on-site rapid analysis, unable to directly analyze solid and liquid samples, etc., and achieves a reasonable structure and wide applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

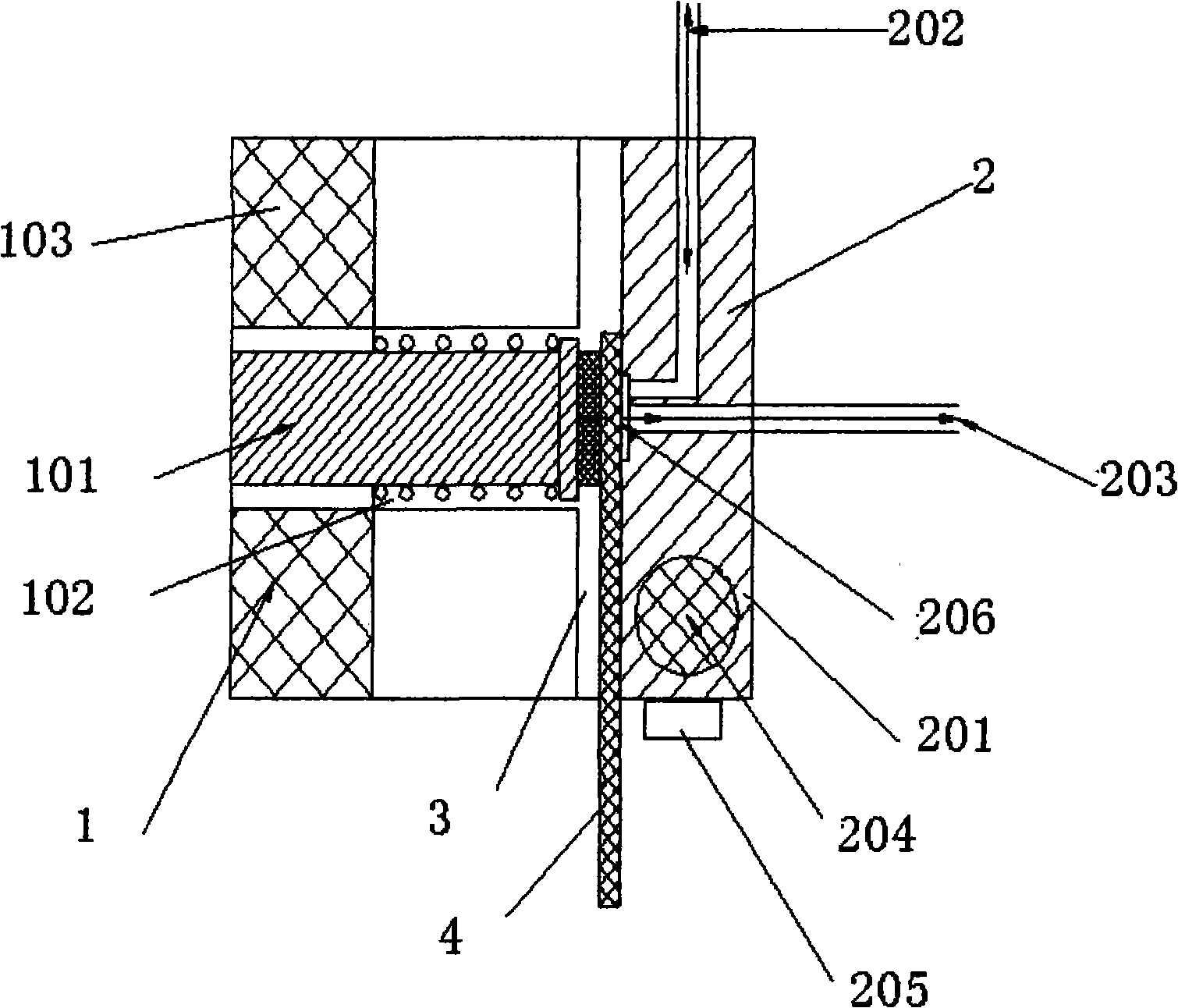

[0022] A surface air flow purging thermal desorption sampling device, characterized in that: the surface air flow purging thermal desorption sampling device includes a fixed control device (1) for controlling whether the sample attachment sheet is clamped or not, The surface airflow purging device (2), the gap formed between the two is a sample slot (3) for inserting a sample attachment sheet; between the fixed control device (1) and the surface airflow purging device (2) Fixed connection.

[0023] The surface air flow purging device (2) includes a thermal analysis body (201), a gas channel one (202), a gas channel two (203), a heating rod (204), a temperature control device (205), a thermal The surface air flow formed between the concave part of the analysis body (201) and the sample attachment sheet sweeps the thermal analysis cell (206);

[0024] Gas channel 1 (202) and gas channel 2 (203) are fixedly connected inside the thermal analysis body (201) respectively, and the h...

Embodiment 2

[0029] A surface air flow purging thermal desorption sampling device, characterized in that: the surface air flow purging thermal desorption sampling device includes a fixed control device (1) for controlling whether the sample attachment sheet is clamped or not, The surface airflow purging device (2), the gap formed between the two is a sample slot (3) for inserting a sample attachment sheet; between the fixed control device (1) and the surface airflow purging device (2) Fixed connection.

[0030] The surface air flow purging device (2) includes a thermal analysis body (201), a gas channel one (202), a gas channel two (203), a heating rod (204), a temperature control device (205), a thermal The surface air flow formed between the concave part of the analysis body (201) and the sample attachment sheet sweeps the thermal analysis cell (206);

[0031] Gas channel 1 (202) and gas channel 2 (203) are fixedly connected inside the thermal analysis body (201) respectively, and the h...

Embodiment 3

[0036] A surface air flow purging thermal desorption sampling device, characterized in that: the surface air flow purging thermal desorption sampling device includes a fixed control device (1) for controlling whether the sample attachment sheet is clamped or not, The surface airflow purging device (2), the gap formed between the two is a sample slot (3) for inserting a sample attachment sheet; between the fixed control device (1) and the surface airflow purging device (2) active connection.

[0037] The surface air flow purging device (2) includes a thermal analysis body (201), a gas channel one (202), a gas channel two (203), a heating rod (204), a temperature control device (205), a thermal The surface air flow formed between the concave part of the analysis body (201) and the sample attachment sheet sweeps the thermal analysis cell (206);

[0038] Gas channel 1 (202) and gas channel 2 (203) are respectively fixedly connected inside the thermal analysis body (201), the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com