Collecting ring used for alternating-current generator and manufacturing method thereof

A technology of alternator and manufacturing method, which is applied in the manufacture of slip rings, collectors, rotating collectors, etc., can solve problems such as short circuit between positive and negative poles of collector rings, high process requirements, and potential safety hazards of generators, and achieve Avoid positive and negative short circuit, optimize the manufacturing process, and provide the effect of reliability

Inactive Publication Date: 2008-10-29

SHANGHAI VALEO AUTOMOTIVE ELECTRICAL SYST

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, since the lead-out wires of the negative electrode need to pass through the inner side of the positive electrode ring, the process of injection molding the lead-out wires of the positive and negative electrodes requires high process requirements, and because the lead-out wires are prone to displacement during the injection molding process, it is easy to use A short circuit occurs during the

However, due to the material defect of the copper ring, during the machining process, there are copper scraps attached to the collector ring, and the copper scraps are too small to be found and cleaned, so it is easy to cause a short circuit between the positive and negative poles of the collector ring. And then cause a safety hazard to the generator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

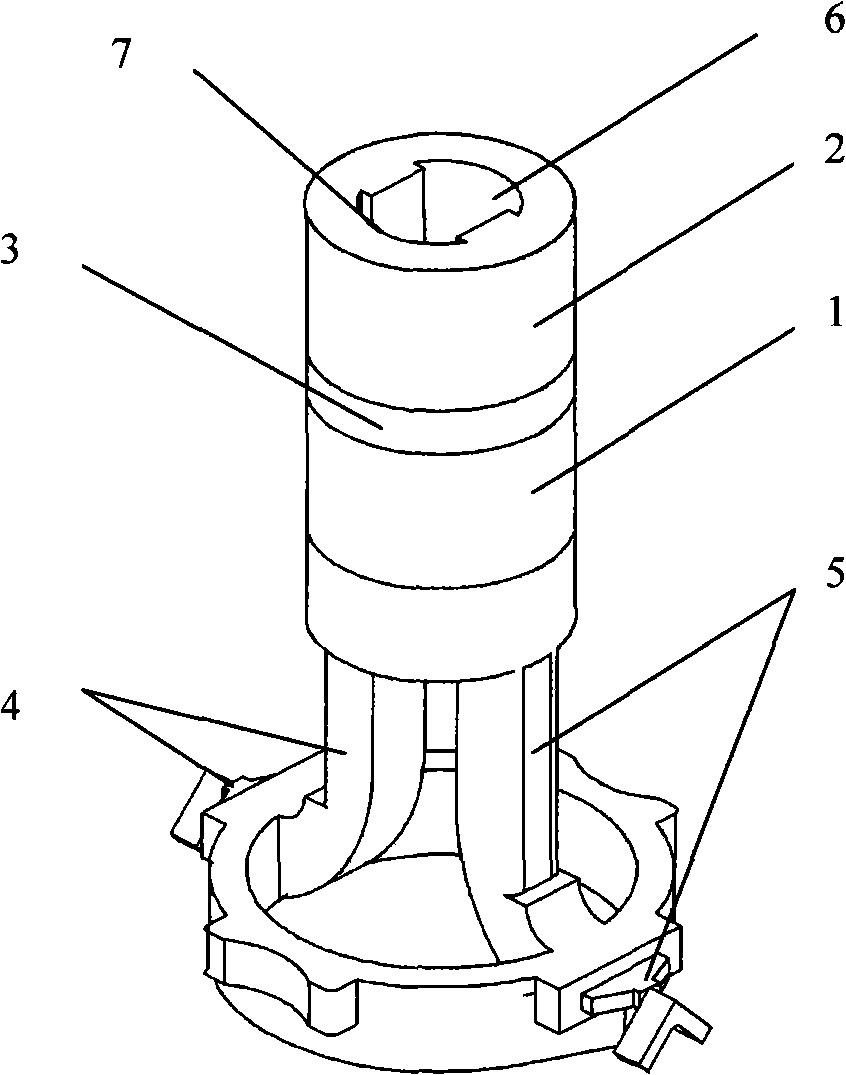

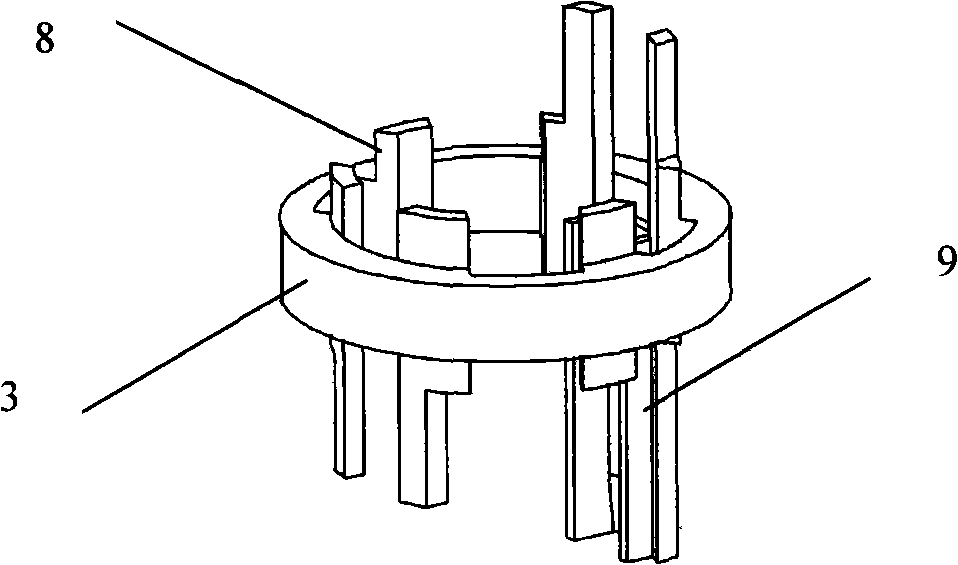

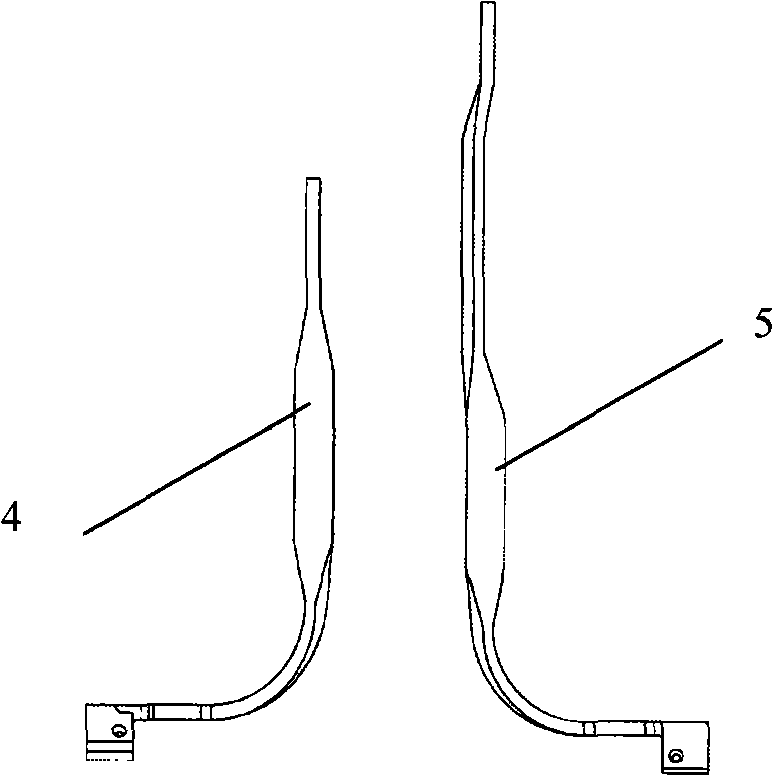

The invention discloses a collector ring applied to alternators and a manufacturing method thereof, which can retain and simplify the characteristic of the overall shaping of the collector rings and avoid the defect of short circuit between the positive and negative electrodes of collector rings, thereby optimizing the manufacture technique of collector rings. The collector ring comprises a positive electrode ring, a negative electrode ring, lead wires of the positive electrode ring and the negative electrode ring, and, an insulation caulking ring arranged between the positive electrode ring and the negative electrode ring and used for separating the positive electrode ring and the negative electrode ring. The manufacturing method of the collector ring is that: firstly, the positive electrode ring and the negative electrode ring of the collector ring are processed respectively; secondly, the positive electrode ring and the negative electrode ring are positioned at the upper end and the lower end of the insulation caulking ring respectively; thirdly, the positive electrode ring, the negative electrode ring and the insulation caulking ring are injected integrally.

Description

Slip ring applied to alternator and manufacturing method thereof technical field The invention relates to an alternator part for automobiles, in particular to a collector ring applied to the alternator. In addition, it also relates to a slip ring manufacturing method. Background technique In the current manufacturing process of the collector ring of the alternator, it is generally to simplify the manufacturing process of the collector ring. At present, the most practical way is to adopt an integral structure to integrate the positive and negative poles of the collector ring, and then after manufacturing and assembling Perform mechanical processing to separate the positive and negative electrodes. In addition, since the lead-out wires of the negative electrode need to pass through the inner side of the positive electrode ring, the process of injection molding the lead-out wires of the positive and negative electrodes requires high process requirements, and because the lea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01R39/08H01R43/10

Inventor 叶勤书李华锋张卫洁

Owner SHANGHAI VALEO AUTOMOTIVE ELECTRICAL SYST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com