Method for manufacture of ultra-low carbon steel slab

一种制造方法、超低碳的技术,应用在制造工具、铸造设备、铸造熔融物容器等方向,达到防止喷嘴堵塞的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

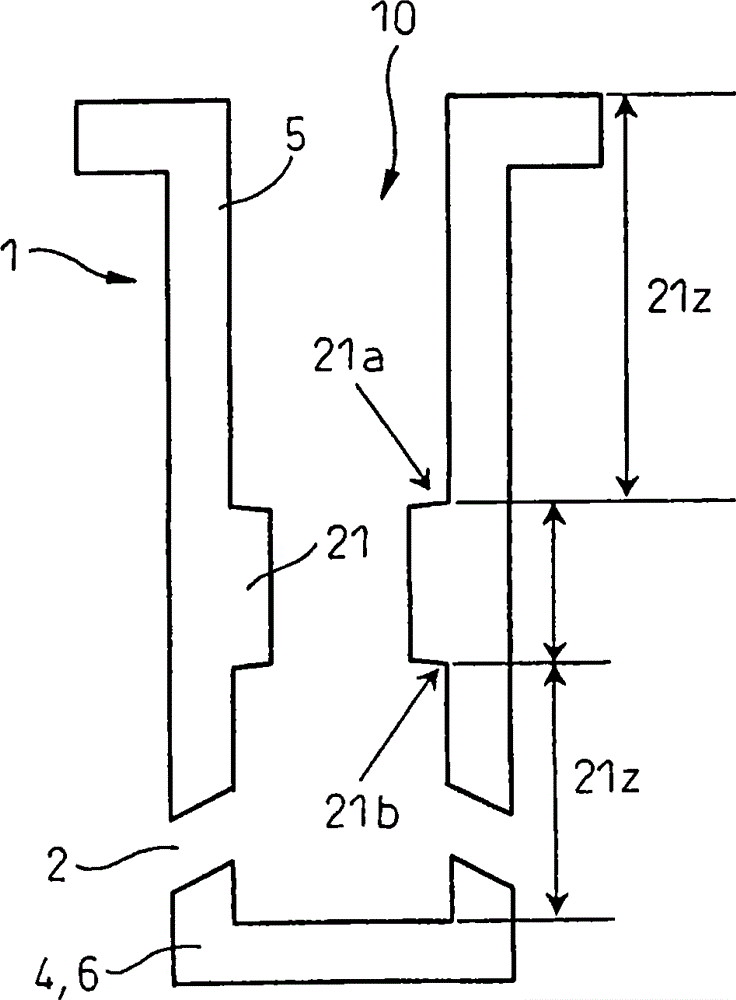

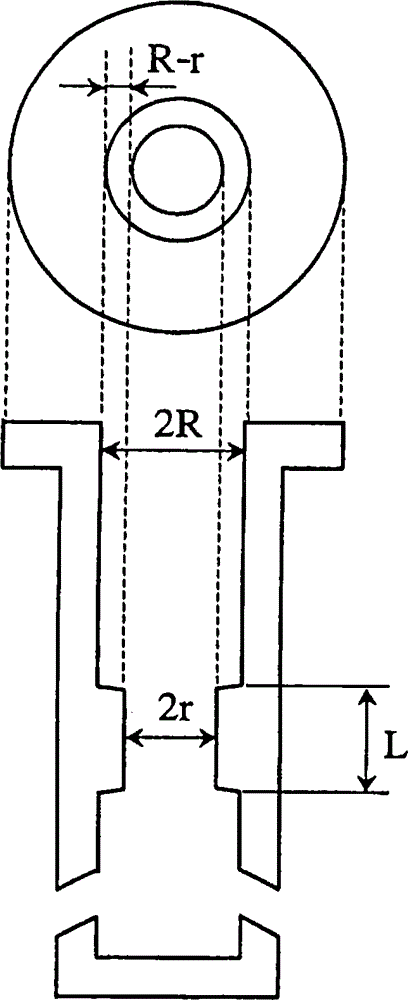

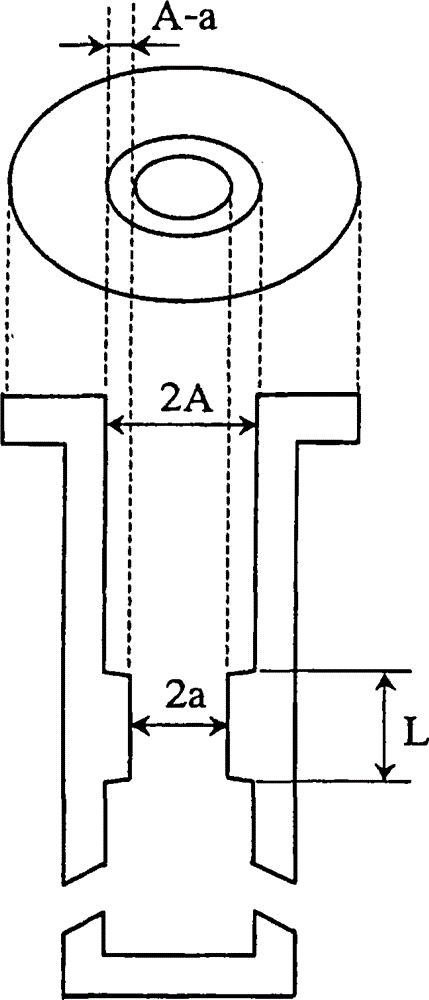

[0139] Hereinafter, by enumerating examples and comparative examples (refer to Table 1), the use of submerged nozzles with various shapes (refer to Table 1) Figure 1~6 ) of the present invention will be described.

[0140]

Embodiment 1-1

[0142] Ti was added to 300 tons of molten steel in a ladle whose carbon concentration was 0.002% by mass by refining in a converter and treated by a vacuum degassing device, deoxidized, refluxed for 6 minutes, and then Ce and La were mixed in the mass ratio Ce / La =1.3 was added as a Ce—La alloy, and refluxed for 3 minutes to melt molten steel with a Ti concentration of 0.03% by mass, a total concentration of Ce and La of 0.01% by mass, and a Ce concentration / La concentration of 1.3.

[0143] The molten steel was cast into a slab with a thickness of 250 mm and a width of 1600 mm under the condition of no Ar gas (flow rate 0 Nl / min) by continuous casting.

[0144] The cross-sectional shape of the dipping nozzle is a perfect circle with an outer diameter of 150 mm and an inner diameter of 85 mm. The material of the inner hole is alumina graphite.

[0145] The length from the upper end of the inner hole to the upper end of the discharge hole is 590 mm, and the inner hole is strai...

Embodiment 1-2

[0152] Ti was added to 300 tons of molten steel in a ladle whose carbon concentration was 0.002% by mass by refining in a converter and treated by a vacuum degassing device, deoxidized, refluxed for 6 minutes, and then Ce and La were mixed in the mass ratio Ce / La =1.3 was added as a Ce—La alloy, and refluxed for 3 minutes to melt molten steel with a Ti concentration of 0.03% by mass, a total concentration of Ce and La of 0.01% by mass, and a Ce concentration / La concentration of 1.3.

[0153] The molten steel was cast into a slab with a thickness of 250 mm and a width of 1600 mm by means of a continuous casting method with an Ar gas flow rate of 2.8 Nl / min blown from the upper nozzle of the tundish.

[0154] The cross-sectional shape of the dipping nozzle is a perfect circle with an outer diameter of 150 mm and an inner diameter of 85 mm. The material of the inner hole is alumina graphite.

[0155] The length from the upper end of the inner hole to the upper end of the dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com