Transverse remote control straddle carrier

A technology of straddle and traverse, applied in the field of transport vehicles, can solve the problem that high temperature slabs are not suitable for straddle vehicles, and achieve the effects of simple structure, reasonable overall layout and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

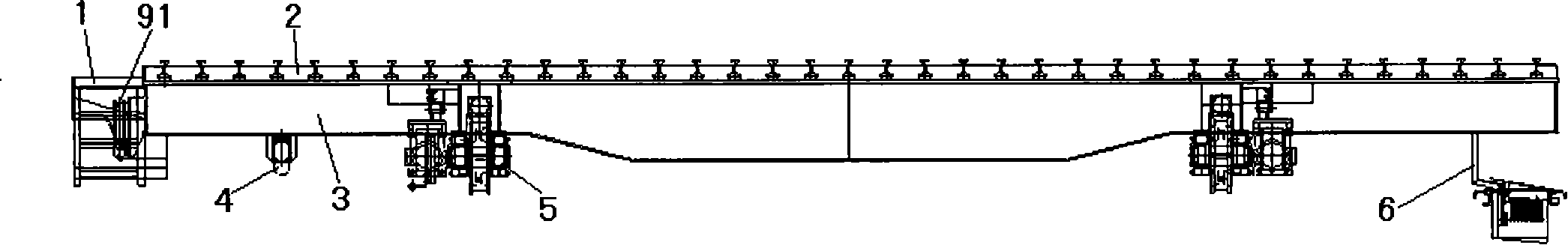

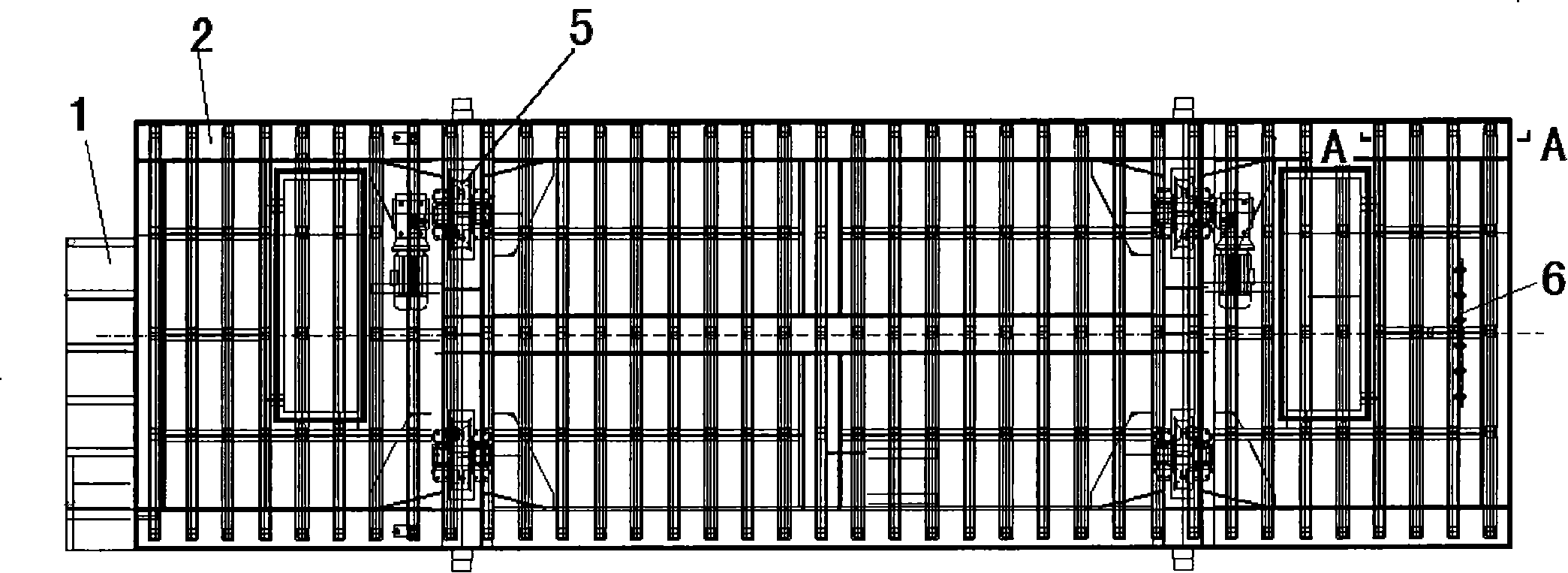

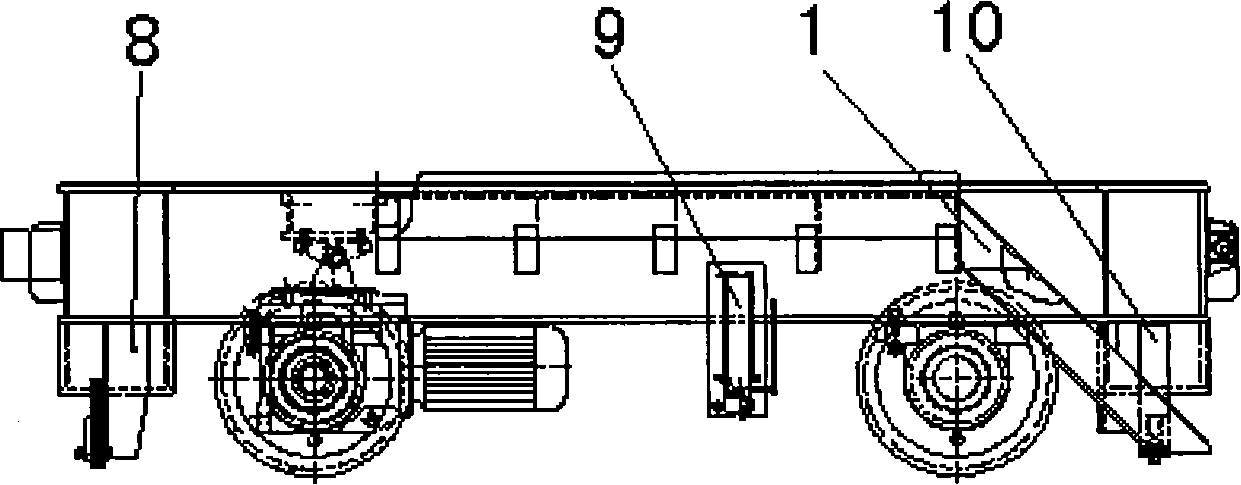

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

[0017] Such as Figure 1~4 As shown, the present invention traverses the remote control over straddle vehicle, comprises the walking ladder 1, the platform 2, the vehicle frame 3 and the travel drive mechanism 5, the described travel drive mechanism 5 is arranged under the vehicle frame 3, and the described platform 2 is fixedly installed on the vehicle The frame 3 also includes an audible and visual alarm device 4, a trolley line device 6, a track cleaner 8, a centralized lubricating device 9 and a proximity switch 10 which are fixedly arranged on the vehicle frame 3, and the traveling drive mechanism 5 is perpendicular to the vehicle The length direction of the frame 3 is arranged, and the table top 2 includes a panel 21, a plurality of rails 22 and a thermal insulation layer 24. The panel 21 is welded and fixed on the frame 3, and the rails 22 are arranged on the panel at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com