Biological-chemical dipolar reactor leaching process

A bioreactor and reactor technology, applied in the field of metallurgical bioengineering, can solve the problems of increasing power consumption, limiting the application value of traditional heap leaching process, and limited leaching rate of sulfide ore, so as to increase economic benefits, improve ore leaching rate, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

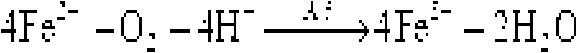

Method used

Image

Examples

Embodiment

[0024] Example Biological-chemical bipolar reaction system leaching of Jinchuan nickel ore

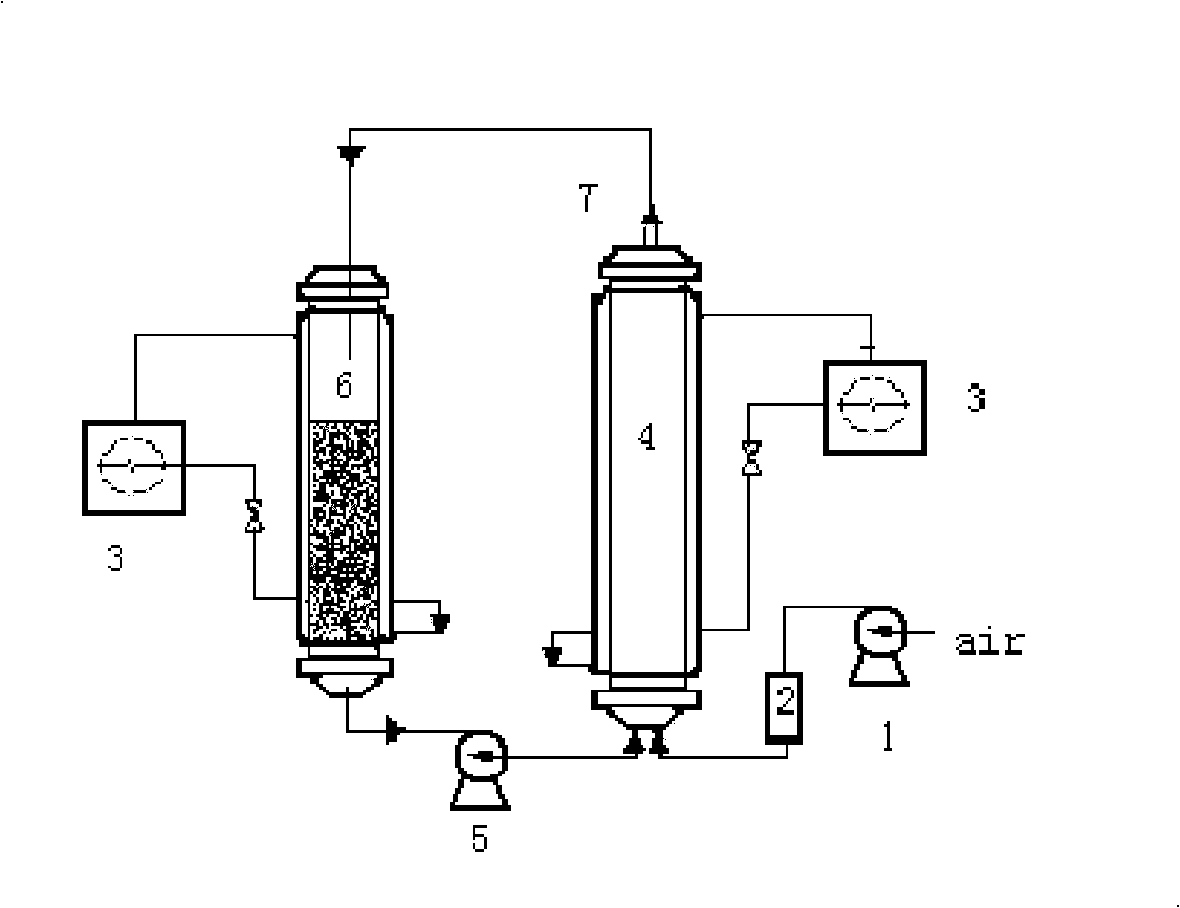

[0025] The main body of the process device is composed of bioreactors and chemical reactors, which are bipolar reactors connected in series. The bioreactor is a hollow glass tube (Φ3.0cm×40cm) with stoppers at both ends, and its effective volume is 270ml. The effective volume of the chemical reactor is 300ml. When the bipolar reactor is in operation, the bioreactor is firstly connected with Thiobacillus ferrooxidans, and then the continuous culture system of Thiobacillus ferrooxidans is started, and the operating temperature is 30°C. When the microbial activity meets the requirements and the effective volumes of the bioreactor and the chemical reactor reach 270ml and 300ml respectively, the process of continuous leaching of Jinchuan nickel ore by Thiobacillus ferrooxidans begins. Wherein, 15g of Jinchuan nickel ore is added into the chemical reactor, and the operating temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com