Dominant cloth roll group in fixation steaming box

A cloth roller set and steaming box technology, applied in the field of color-fixing steaming box, can solve the problems of increased floor space, uneven dyeing of cloth surface, difficult cleaning, etc. The effect of uniform and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

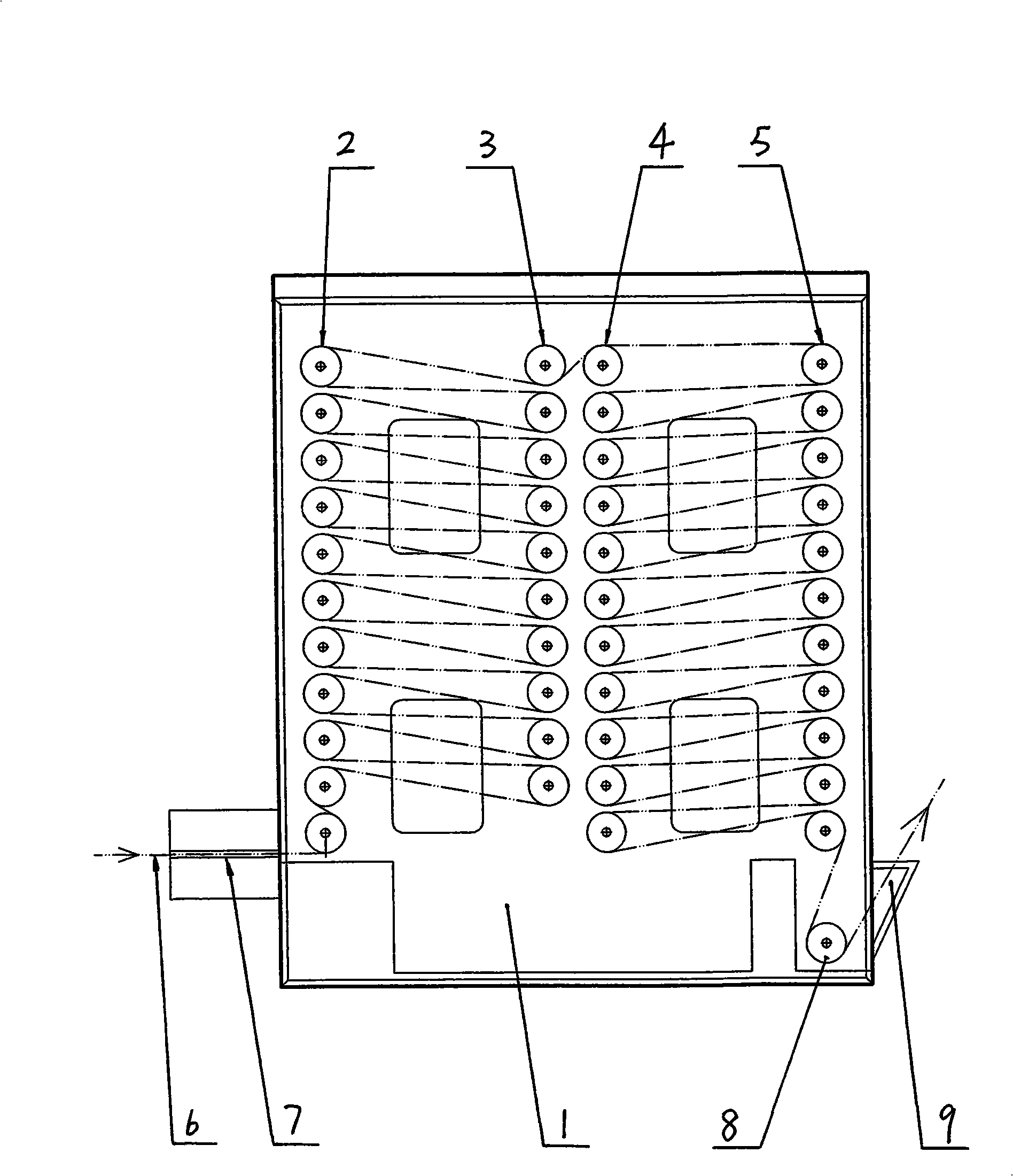

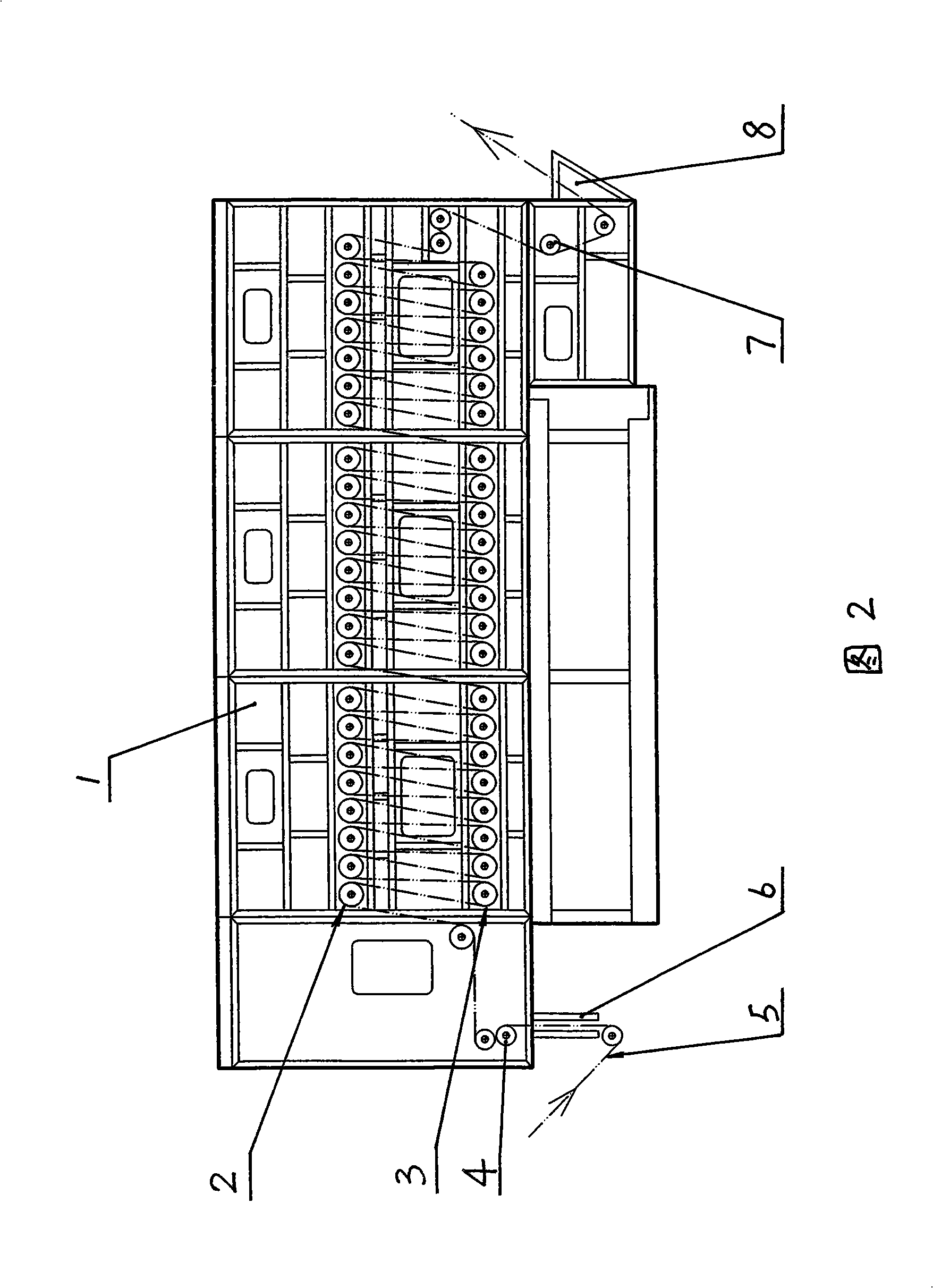

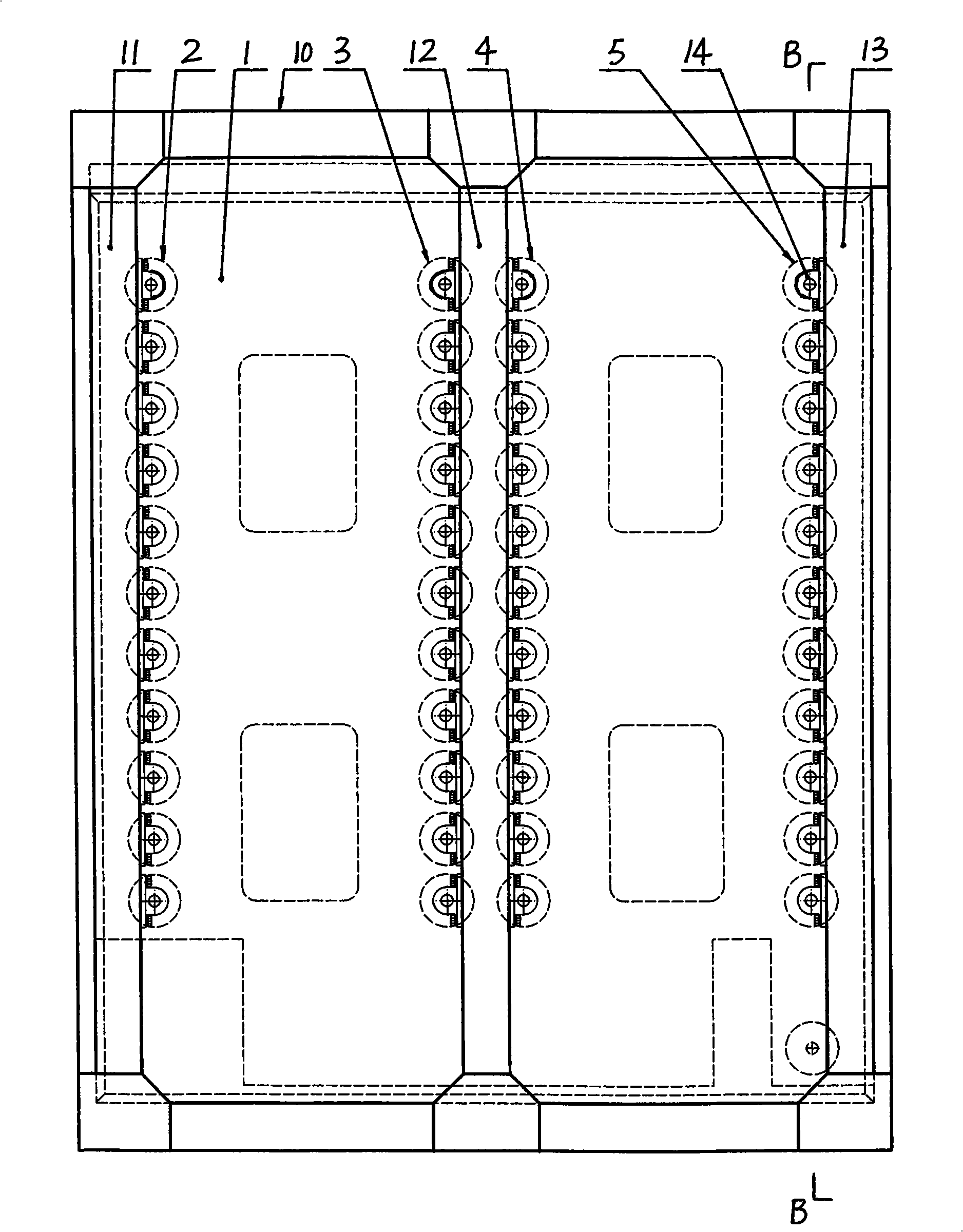

[0012] The technical solutions and advantages of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, it is a preferred embodiment of the present invention, the main cloth roll group in the described fixing color steam box is made up of four rows of main cloth rolls 2,3,4,5, each row of main cloth rolls 2,3 , 4, and 5 are all vertically arranged in the casing 1 of the color-fixing steam box, and each row of leading cloth rollers 2, 3, 4, and 5 is composed of several cloth guiding rollers, and these four rows of leading cloth rollers 2 , 3, 4, 5, every adjacent two rows of 2 and 3, and 4 and 5 respectively constitute a group of partner leading cloth rollers for the operation of fabric 6. When working, the fabric 6 enters the box body 1 from the cloth inlet 7, firstly passes around from the bottom of a group of partner leading cloth rollers 2 and 3, runs to the top, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com