Flat plate type solar heat collector

A solar collector, flat-plate technology, applied to solar collectors, solar thermal energy, solar collectors using working fluid, etc. The effect of reducing production costs and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

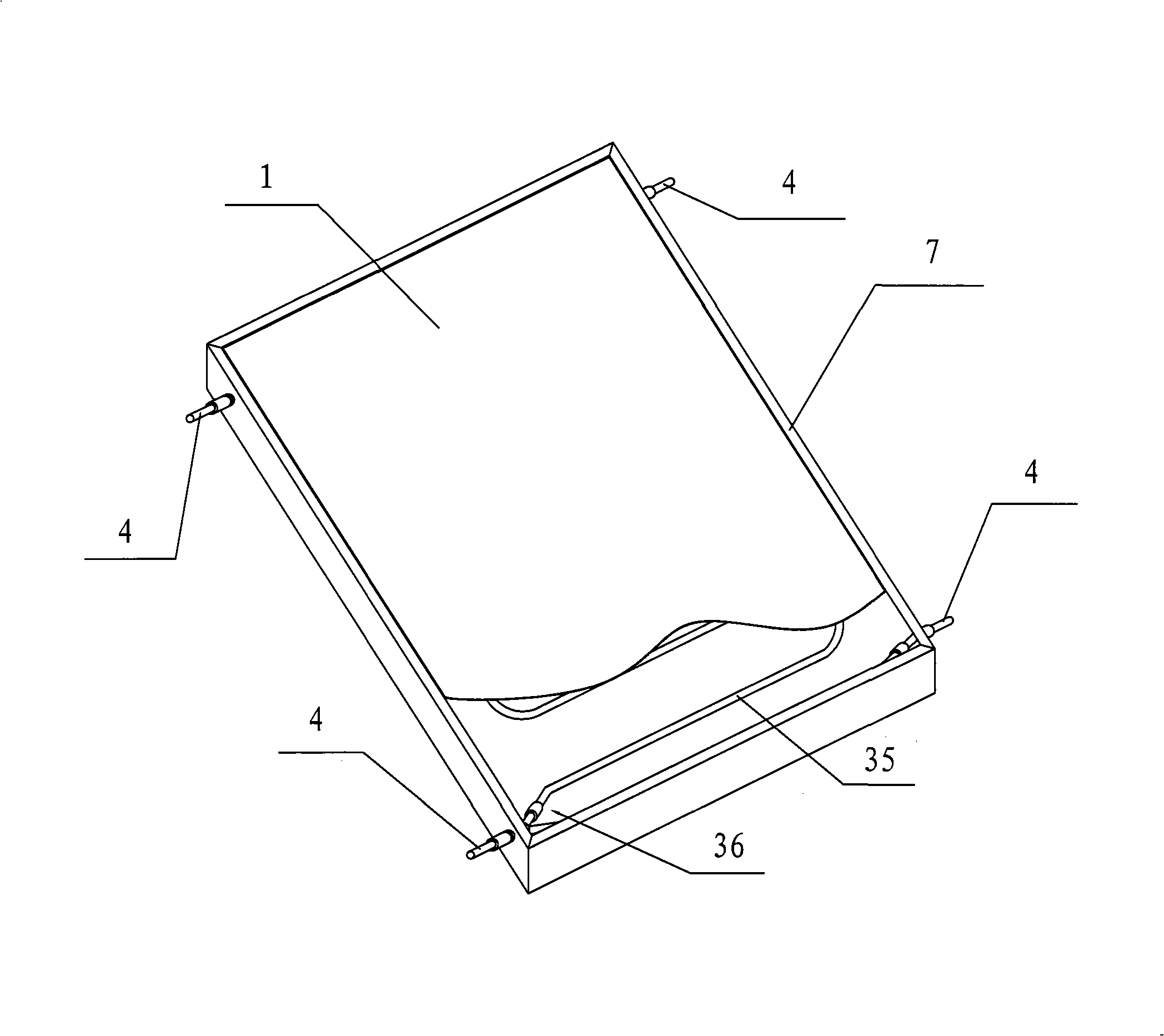

[0020] as attached figure 1 As shown, the flat-plate solar heat collector implemented according to the present invention includes a transparent cover plate 1 of glass, a heat collecting plate 2 made of aluminum, a tubular heat-conducting fluid channel 3, a bottom plate, and is used to connect the transparent cover plate 1, The heat collecting plate 2, the heat transfer fluid channel 3, the frame 7 fixed by the bottom plate, and the heat insulation cotton filled between the heat transfer fluid channel 3 and the bottom plate.

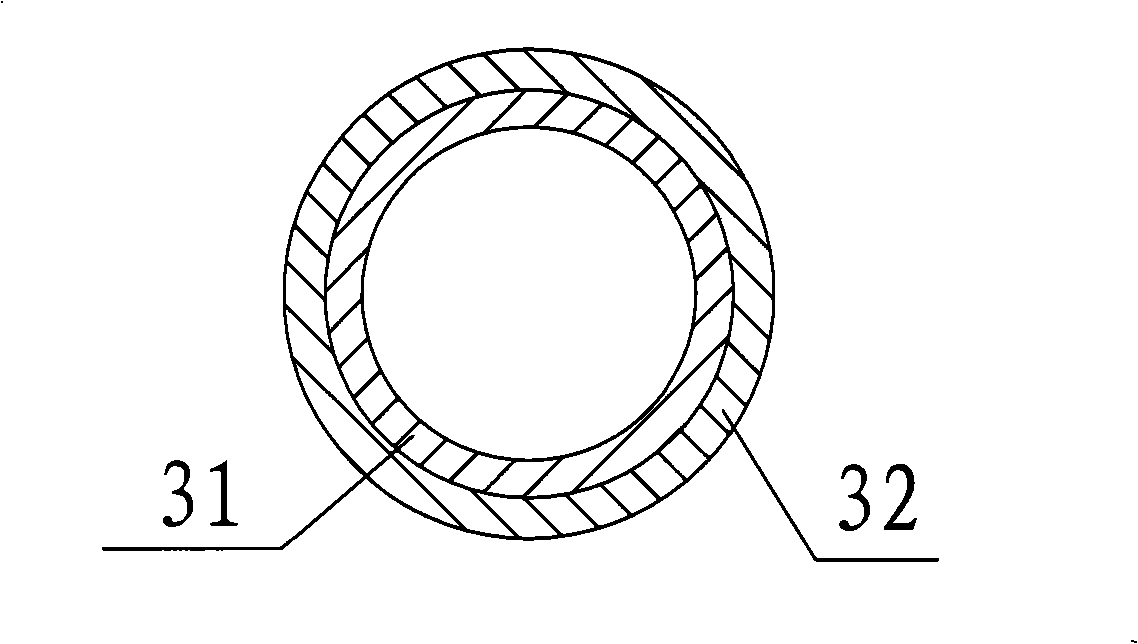

[0021] Wherein, the cross-sectional structure of the pipe fittings used in the heat transfer fluid channel 3 is as attached figure 2 As shown, it consists of an inner layer 31 made of copper and an outer layer 32 made of aluminum. And the heat conducting fluid channel 3 is welded to the lower surface of the heat collecting plate 2 .

[0022] A heat collecting film for absorbing heat energy is coated on the heat collecting plate 2 . The heat-collecting...

Embodiment 2

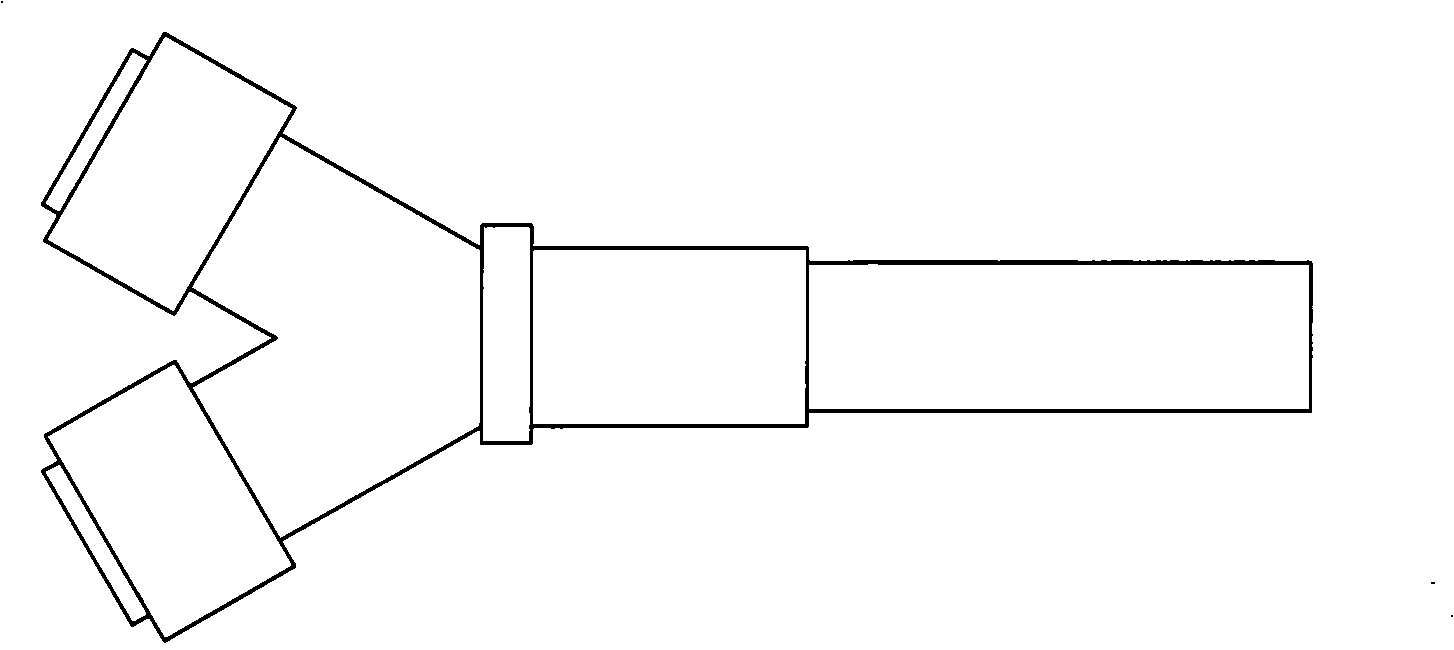

[0029] The difference between embodiment 2 and embodiment 1 is that the installation position of the fluid delivery pipe 4 is different, which is located on the other side of the heat collecting tube. Therefore as attached Image 6 As shown, during installation, the second end is directly connected to the fluid delivery pipe 4 , and the end of the extension pipe 41 is closed.

[0030] Since it is impossible to predict the arrangement position of the fluid delivery pipeline 4 during installation, it is impossible to determine from which side the fluid will flow into the serpentine pipe 35, so the three-way joint 36 is provided to facilitate installation and construction.

[0031] It is also possible to set tee joints 36 and extension pipes 41 at both ends of the fluid delivery pipeline 3, and reserve 4 pipeline joints on the 4 corners of the heat collector, so as to facilitate construction according to the position of the fluid delivery pipeline 4. Select the connector to be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com