Capacitance type touch control panel and manufacturing method thereof

A technology of capacitive touch and manufacturing method, which is applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., and can solve problems such as eye discomfort and visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

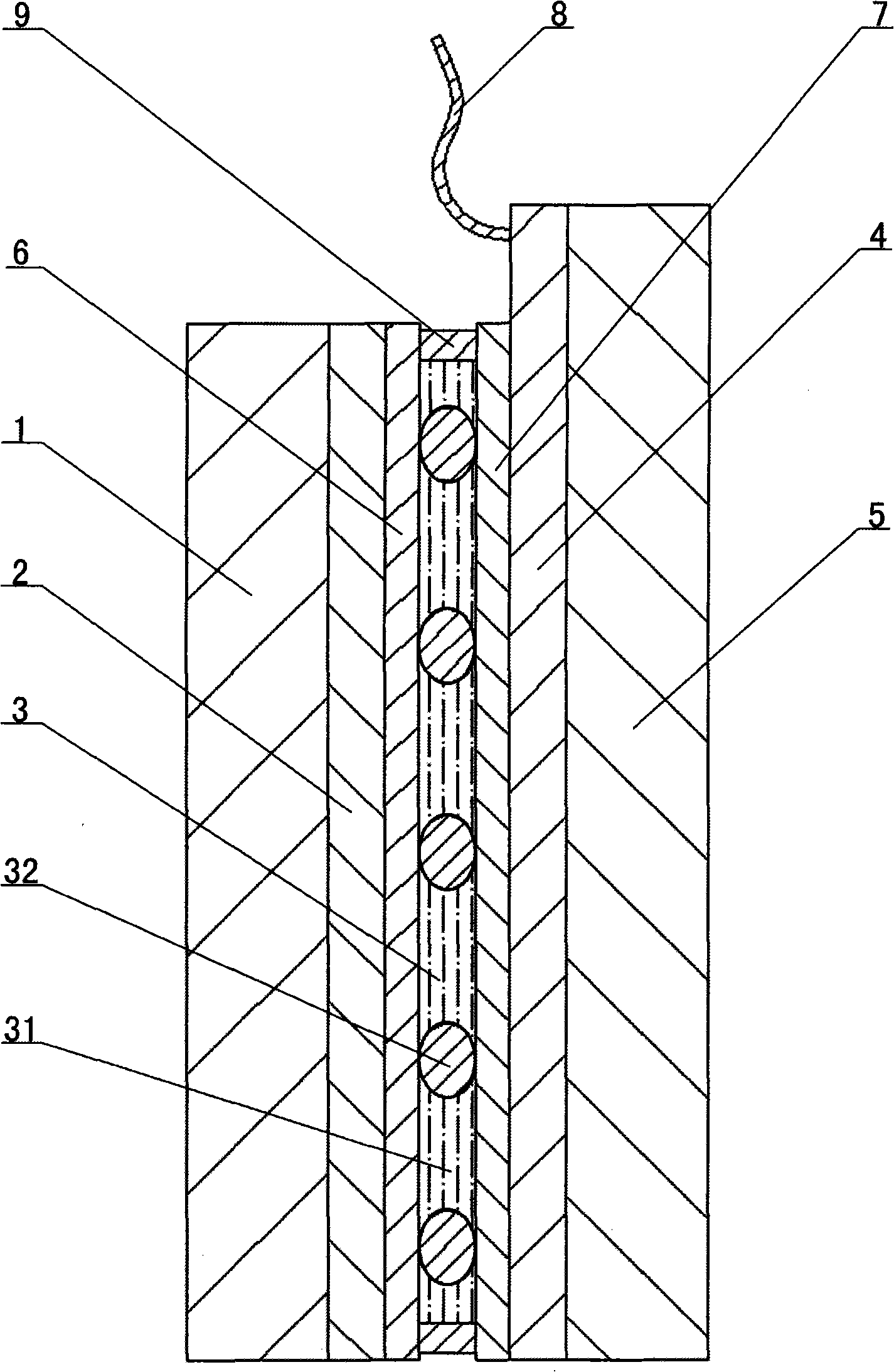

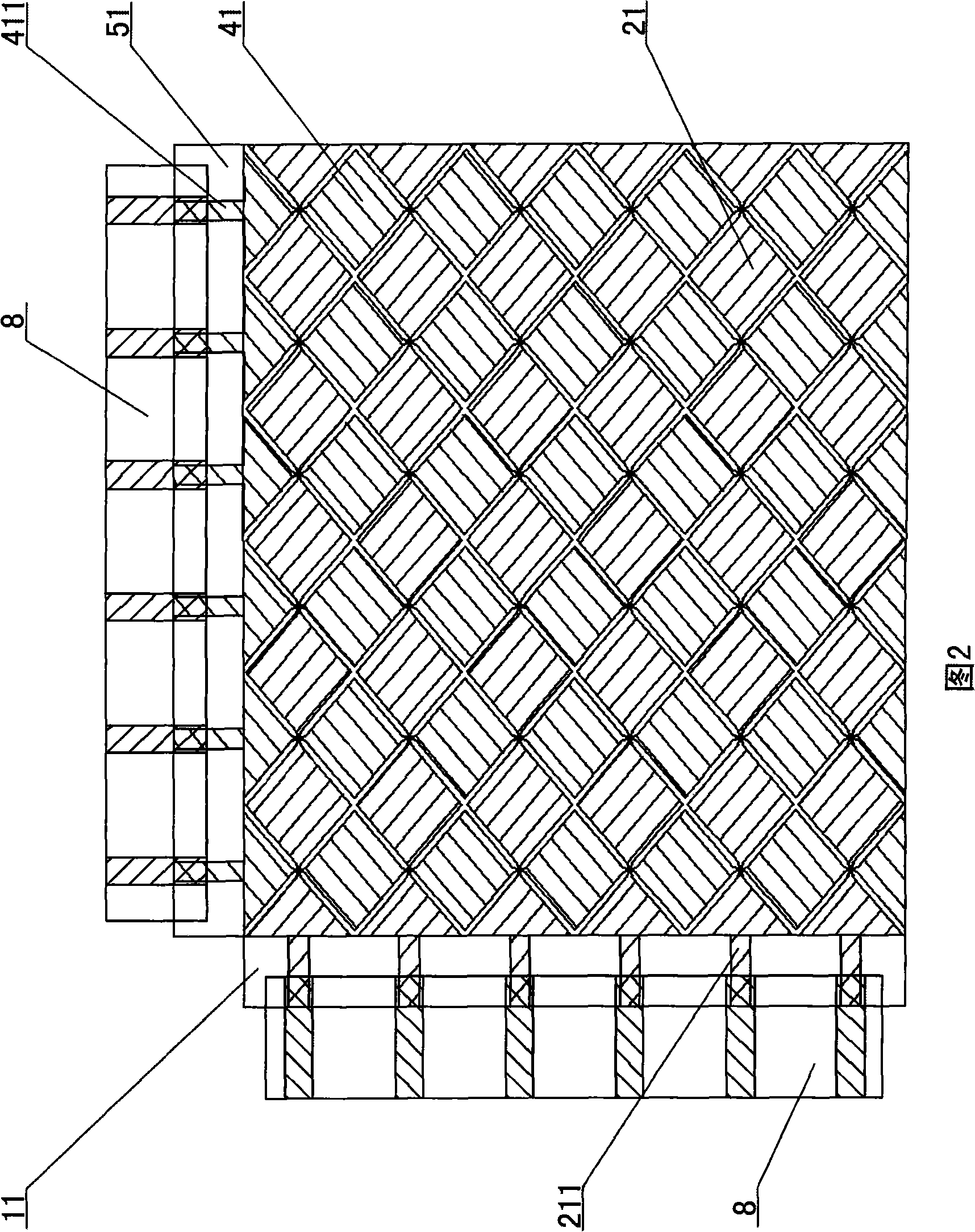

[0039] like figure 1 As shown in FIG. 2, this capacitive touch panel includes in order a first transparent insulating layer 1, a first transparent conductive material layer 2 containing an X-axis trace 21, a second transparent insulating layer 3, and a layer containing a Y-axis trace 41. The second transparent conductive material layer 4 and the third transparent insulating layer 5, the X-axis trace 21 has a first trace contact 211, and the Y-axis trace 41 has a second trace contact 411; the second transparent insulating layer 3 and the first transparent conductive material A first transparent alignment layer 6 is arranged between the layers 2, a second transparent alignment layer 7 is arranged between the second transparent insulating layer 3 and the second transparent conductive material layer 4; the second transparent insulating layer 3 is composed of liquid crystal 31, and the liquid crystal 31 is distributed with insulating particles (that is, the liquid crystal 31 is fil...

Embodiment 2

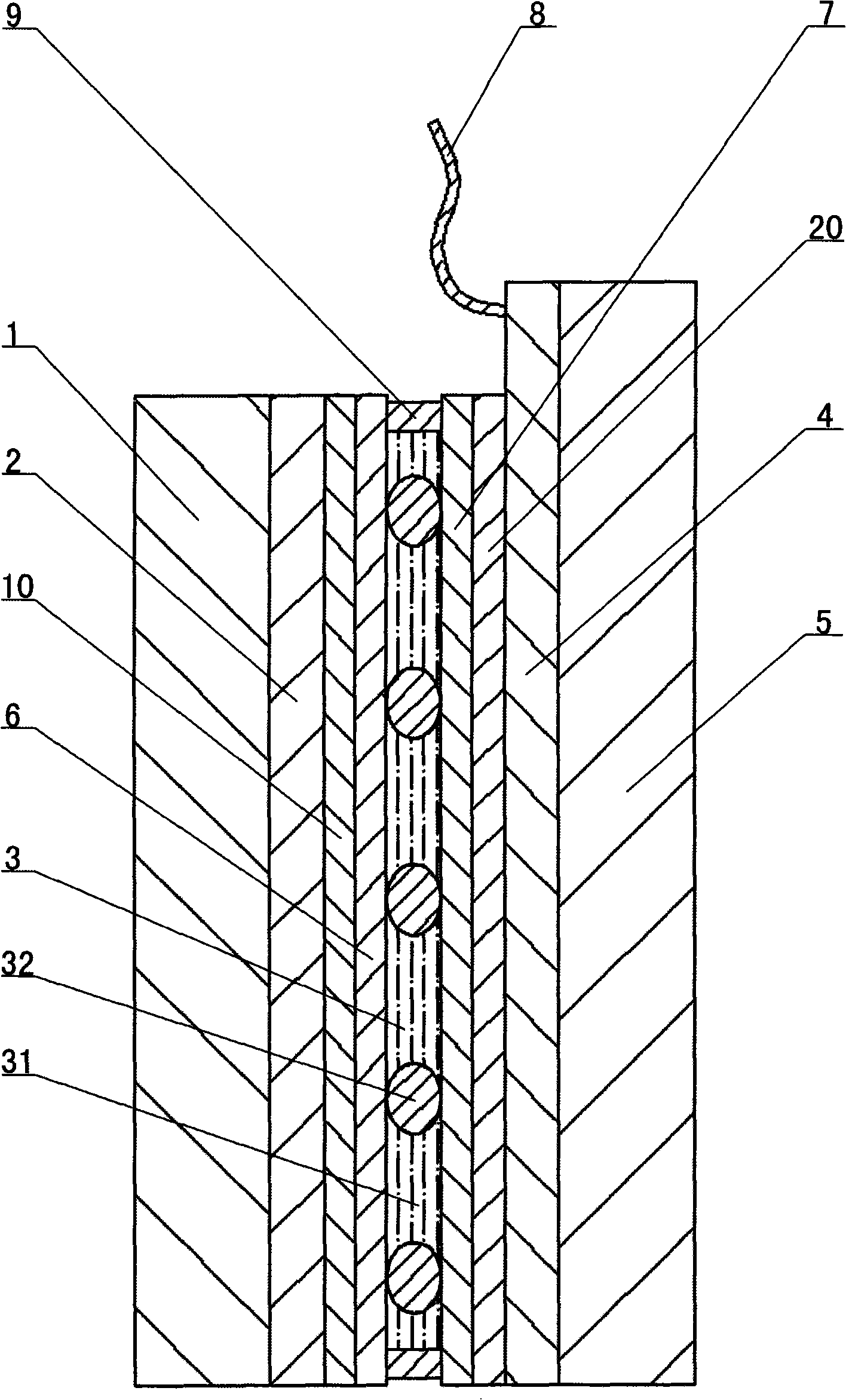

[0054] like image 3 As shown, a layer of transparent insulating material film layer 10 is arranged between the first transparent conductive material layer 2 and the first transparent alignment layer 6 of this capacitive touch panel, and the second transparent conductive material layer 4 and the second transparent alignment layer There is a layer of transparent insulating material film layer 20 between 7, and the transparent insulating material film layer 10 and the transparent insulating material film layer 20 are made of silicon carbide.

[0055] This capacitive touch panel is suitable for color liquid crystal display. The wavelength range of the emitted light of the color liquid crystal display is 380nm~780nm. The center wavelength λ=550nm can be selected as the basis for determining the optical path difference |Δn|d of the second transparent insulating layer , that is, the value of the optical path difference |Δn|d of the second transparent insulating layer. The optical pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com